Method of evaluating durability of torsion beam rear axle on basis of road load

A technology of torsion beam rear axle and evaluation method, which is applied in the direction of vehicle testing, machine/structural component testing, measuring devices, etc., can solve problems such as blankness, lack of durability evaluation methods and means, and weak technical foundation, and achieve improvement Effects of Speed and Accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. Although the following content provides detailed implementation methods and specific operation processes, the scope of protection of the present invention is not limited to the following exemplary embodiments.

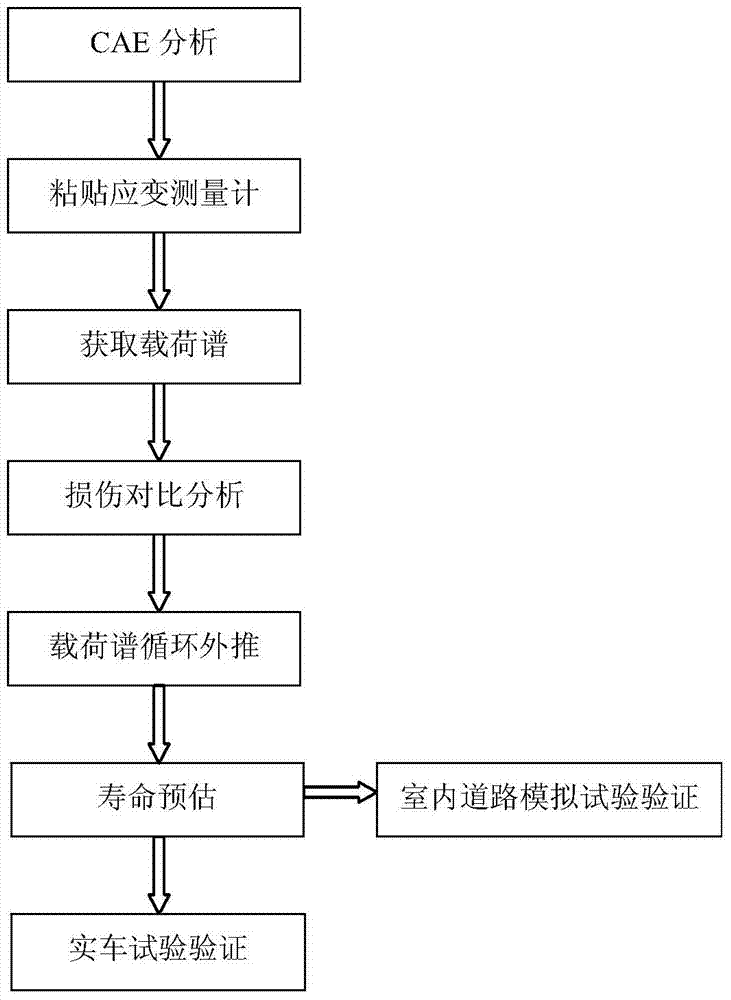

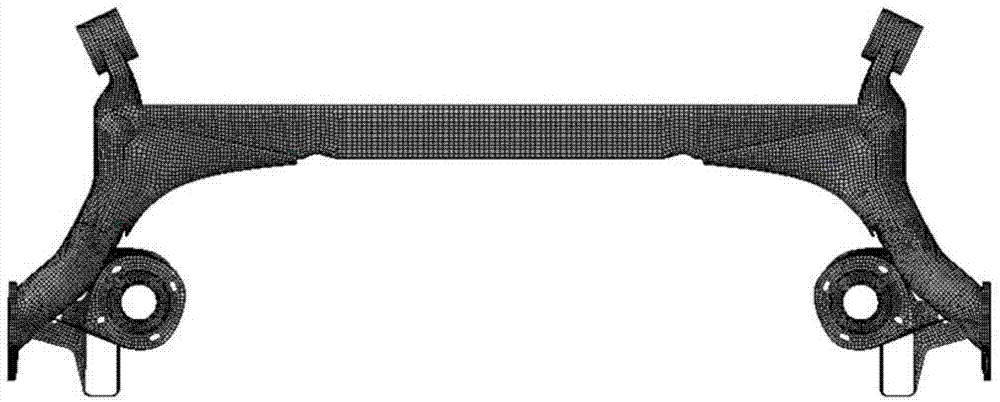

[0034] combine figure 1 , in step one, use CAE analysis software to establish the rear axle (such as figure 2 shown) finite element model, and through finite element analysis under typical working conditions such as acceleration, braking, steering, torsion, etc., the measurement position of the rear axle strain load is determined by combining the dangerous parts of the rear axle under typical working conditions with test experience . That is to use the CAE finite element analysis method to simulate the force of the rear axle of the vehicle in the vehicle, and according to the stress cloud diagram and force direction calculated by CAE, deter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com