Display panel, manufacturing method thereof, and display device

A display panel and pixel unit technology, applied to static indicators, instruments, nonlinear optics, etc., can solve problems such as severe flickering and poor display effects, and achieve the effects of improving crosstalk, improving display effects, and suppressing flickering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

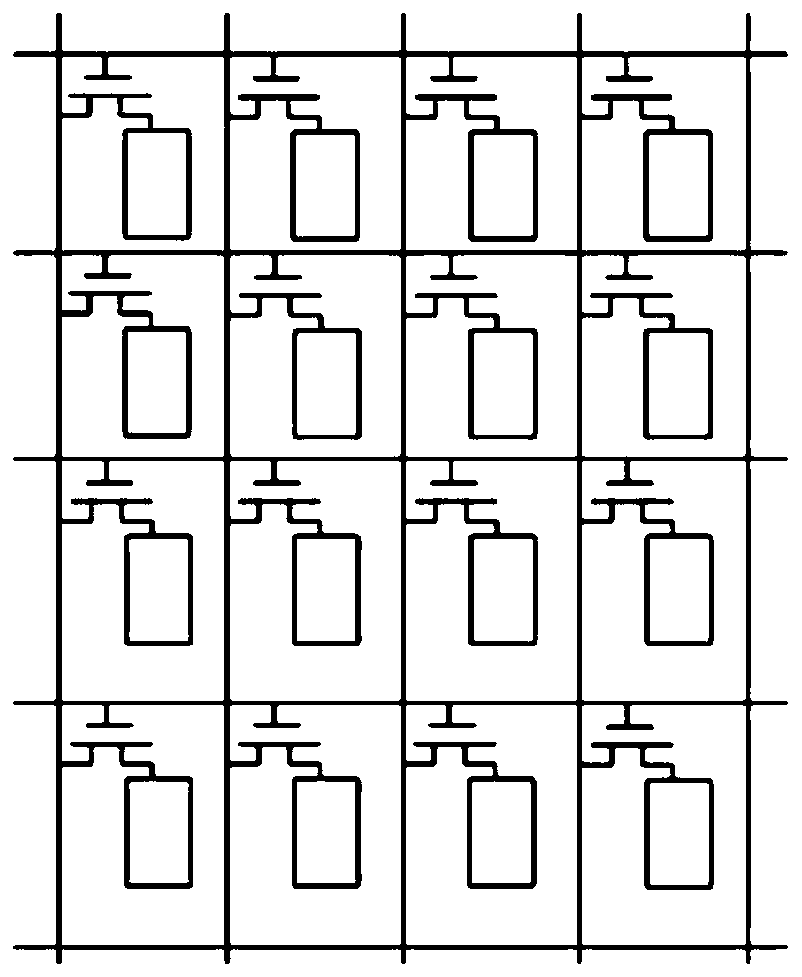

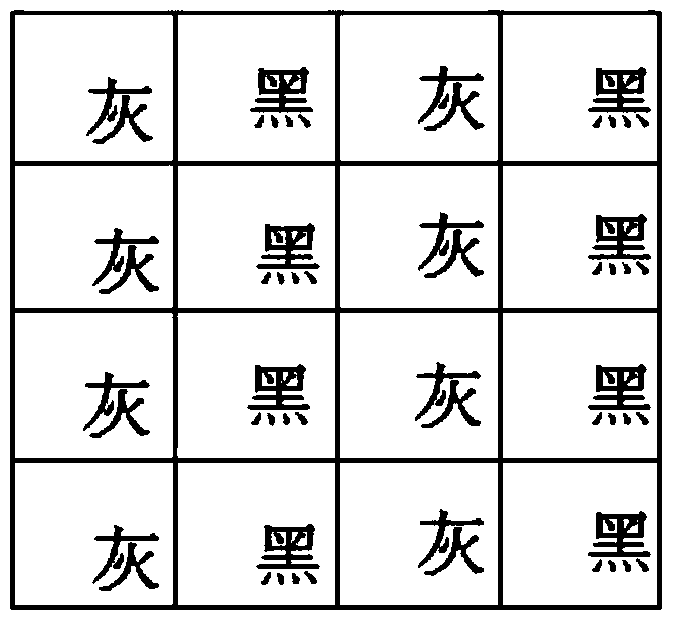

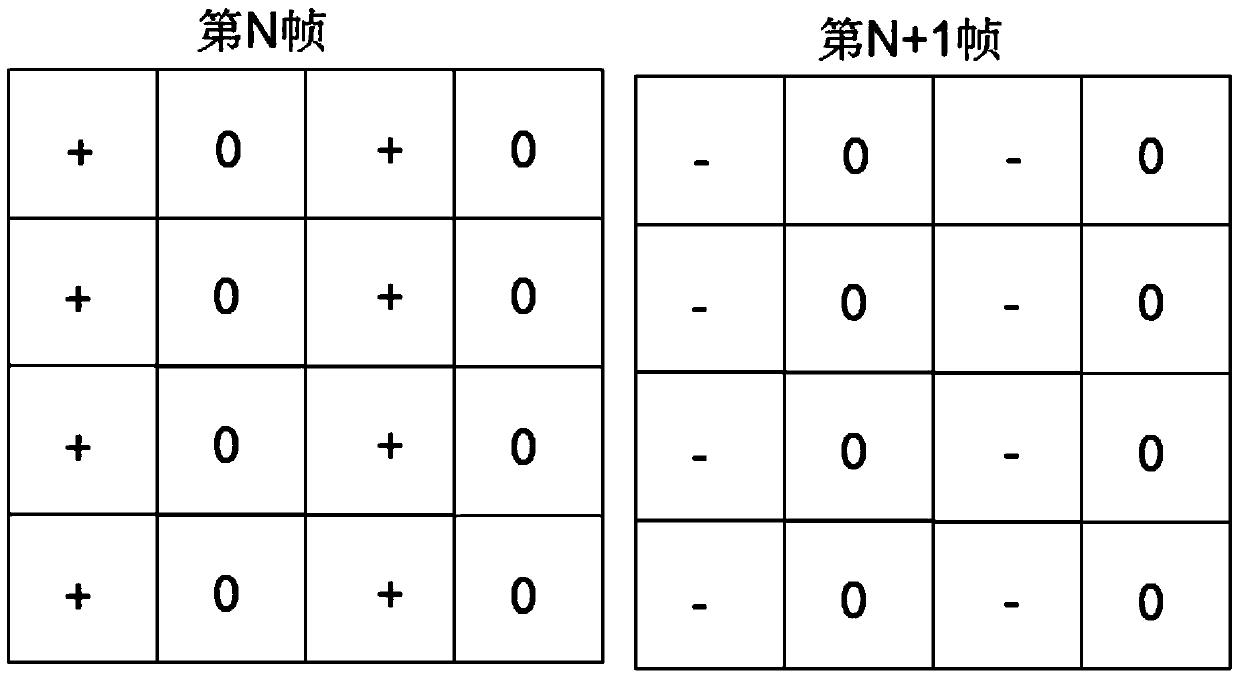

[0077] Embodiment 1 of the present invention provides a display panel 1, such as Figure 4 As shown, a substrate 10 is included, and the substrate 10 can be a glass substrate, a resin substrate, etc., and a plurality of gate lines 11 and a plurality of data lines 12 are arranged on the substrate 10, and the gate lines 11 and the The data lines 12 are insulated and intersect; the gate lines 11 and the data lines 12 are surrounded by a plurality of sub-pixels 13 distributed in an array; the sub-pixels 13 include pixel switches 14, pixel electrodes 15 and common electrodes 16. The pixel electrode and the common electrode form a horizontal electric field; the display panel 1 includes a plurality of first pixel units P1 and a plurality of second pixel units P2; the first pixel units P1 and the second pixel units P2 respectively include Two sub-pixels that are adjacent along the direction of the gate line and have the same electric field direction; from Figure 4 It can be seen tha...

Embodiment 2

[0135] Embodiment 2 of the present invention provides a display panel, the common electrode of the sub-pixel in the first pixel unit is arranged on the same layer as the pixel electrode, the branch electrode of the common electrode of the sub-pixel in the first pixel unit is connected to the branch electrode of the pixel electrode The electrodes are insulated and alternately arranged, and the branch electrodes of the pixel electrodes are located at the edges of the sub-pixels in the first pixel unit;

[0136] The common electrode of the sub-pixel in the second pixel unit is arranged on the same layer as the pixel electrode, the branch electrodes of the common electrode of the sub-pixel in the second pixel unit are insulated and alternately arranged with the branch electrodes of the pixel electrode, and the branch electrodes of the common electrode The electrodes are located at edge positions of the sub-pixels in the second pixel unit;

[0137] Wherein, the first pixel unit and...

Embodiment 3

[0144] Embodiment 3 of the present invention provides a method for manufacturing a display panel, the specific process is as follows Figure 21 shown, combined with the structure of the display panel provided in Embodiment 1, such as Figure 4 , Figure 4a , Figure 4b , Figure 4c As shown, the display panel includes a substrate 10, on which a plurality of gate lines 11 and a plurality of data lines 12 are arranged, and the gate lines 11 and the data lines 12 are insulated to cross; The gate line 11 and the data line 12 are surrounded by a plurality of sub-pixels 13 distributed in an array; the sub-pixel 13 includes a pixel switch 14, a pixel electrode 15 and a common electrode 16, and the pixel electrode and the common electrode form a electric field; the display panel 1 includes a plurality of first pixel units P1 and a plurality of second pixel units P2; the first pixel units P1 and the second pixel units P2 respectively include two sub-pixels with the same electric fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com