Current collector for a flow battery

A liquid flow battery and current collector technology, which is applied in the field of current collectors, can solve problems such as flow dead zone, battery concentration polarization deterioration, and electrolyte utilization reduction, and achieve simple preparation process, reduced electrode thickness, and reduced ohmic internal energy. The effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

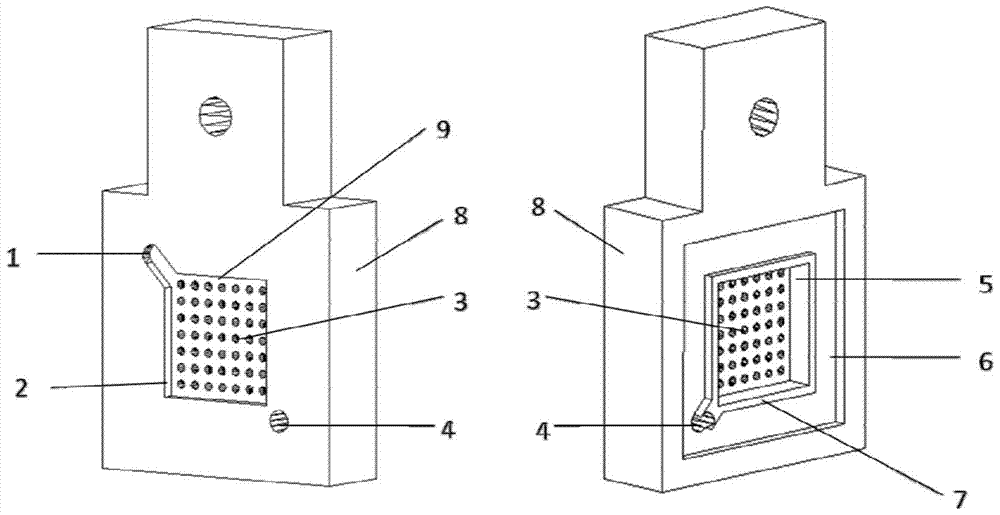

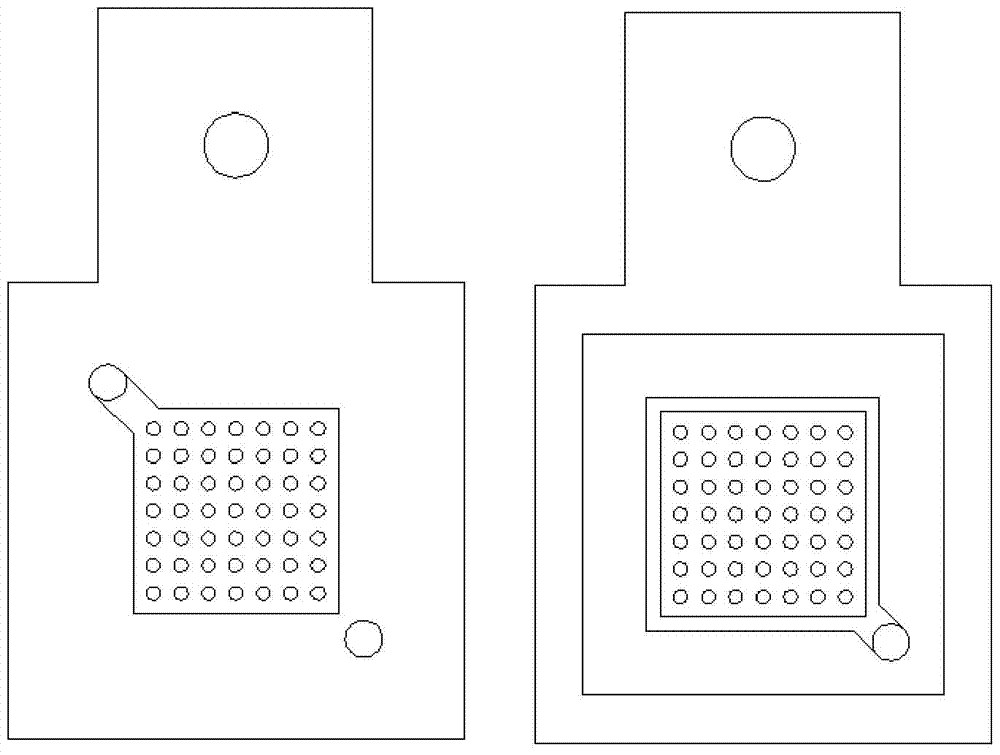

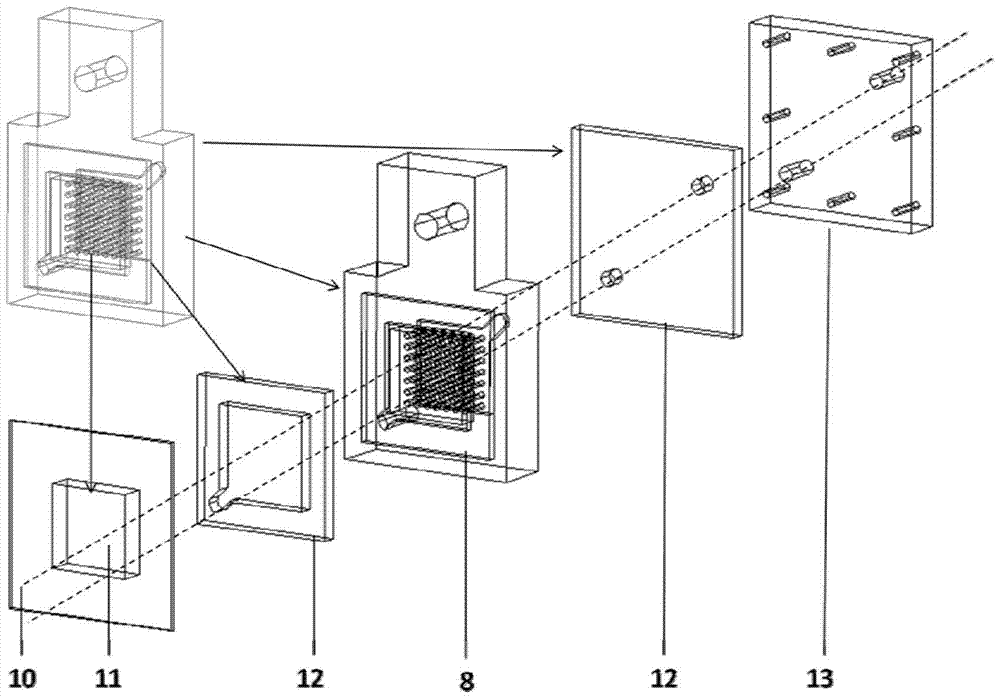

[0032] The thickness of the current collector is 15mm, and the length and width are 50mm; the length and width of the liquid storage groove and the electrode groove are both 30mm; the depth of the liquid storage groove is 1mm; the depth of the electrode groove is 3mm, and the seepage hole is a circular hole structure with a diameter of 1mm , The density of holes in the diagonal area of the liquid in and out is small, and the hole density in the area away from the diagonal line is large; the depth of the sealing groove on the outer edge of the electrode groove is 1mm, and the width of the sealing groove is 1.5mm. The electrode size (length×width×thickness) used in the assembly of the flow battery is 30mm×30mm×6mm, and the electrode compression-stretch ratio is 2; the sealing element is in the shape of a rectangular ring with a thickness of 1mm and a width of 1mm around it. The energy efficiency of the battery tested under the condition of 80mAcm-2 is 81.25%, which is 1% higher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com