Deep ploughing, deep scarification and ridge smashing device

A technology of powder ridge and deep loosening, which is applied in the fields of tillage equipment, application, agricultural machinery and equipment, etc., can solve the problems of poor soil crushing effect, slow plowing speed, and large rotation resistance, and achieves reduced resistance, good effect, high speed quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

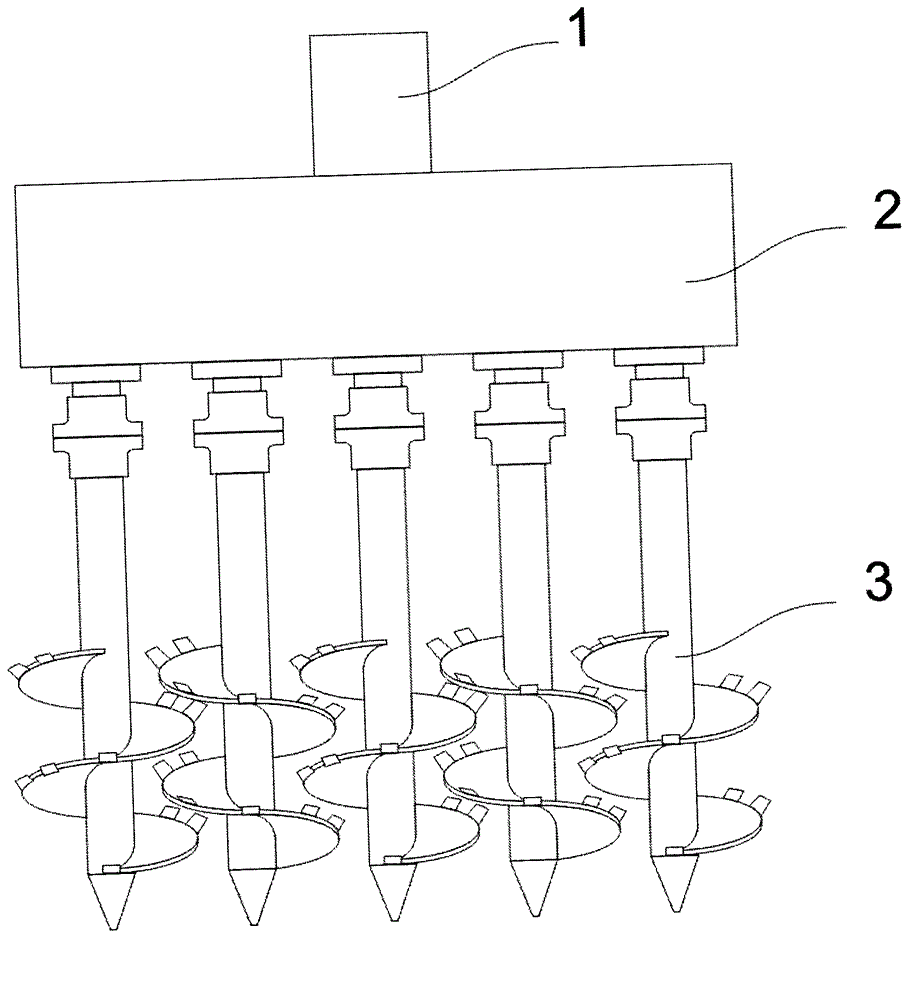

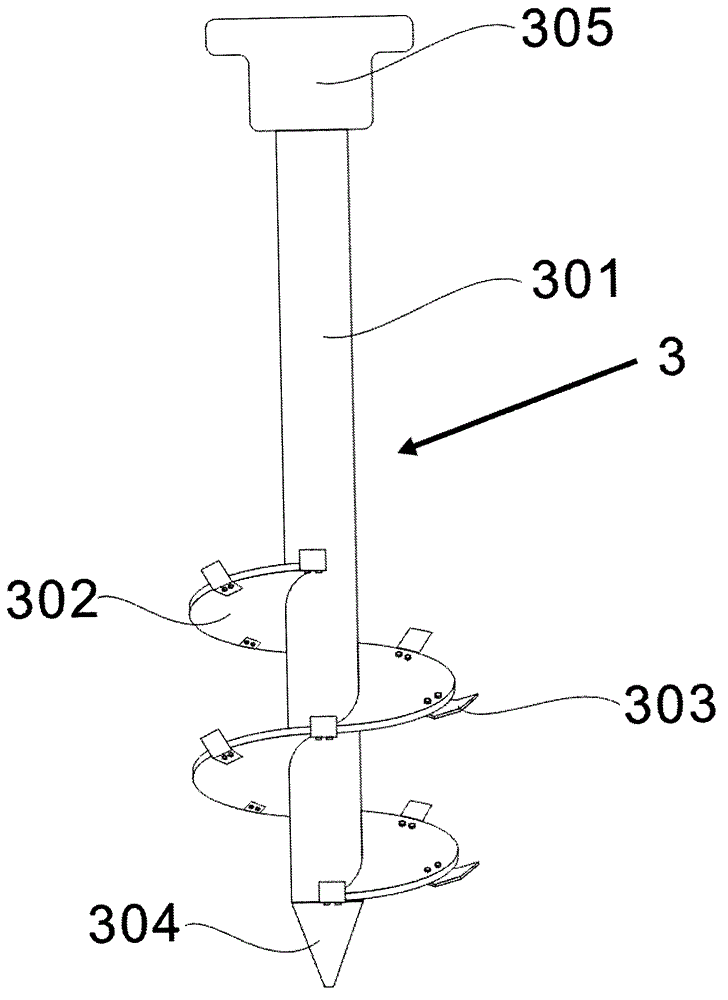

[0014] The device comprises a hydraulic motor 1, a gear transmission case 2 and 5 powder ridge drill bits 3, and the deep plowing and deep loosening powder ridge device can adjust the number of powder ridge drill bits according to the size of the powder ridge area. The power of the hydraulic motor 1 is transmitted to the powder ridge drill bit through the gear transmission box 2. The gears in the transmission box are closely arranged, and the rotation directions of the two adjacent gear shafts are opposite. Among them, the first, third and fifth drill bits Rotate clockwise, the 2nd and 4th drill bits rotate counterclockwise, the spiral direction of the powder ridge blades of the 1st, 3rd and 5th powder ridge drill bits is the same as that of the 2nd and 4th powder ridge drill bits The helical direction of the powder ridge blades is opposite, so that the soil moves upwards along the drill bit, which reduces the travel resistance of the powder ridge drill bit and deep plowing and...

specific Embodiment approach 2

[0017] Such as figure 1 The shown deep plowing and deep loosening powder ridge device includes an electric motor, a transmission box and 3 powder ridge drill bits. The deep plowing and deep loosening powder ridge device can adjust the number of powder ridge drill bits according to the size of the powder ridge area. The power of the hydraulic motor 1 is transmitted to the powder ridge drill bit through the gear transmission box 2. The gears in the transmission box are closely arranged, and the rotation directions of the two adjacent gear shafts are opposite, and the first and third drill bits rotate clockwise. The 2nd drill bit rotates counterclockwise, and the helical direction of the powder ridge blades of the powder ridge drill bits 1 and 3 is opposite to the helical direction of the powder ridge blades of the powder ridge drill bit 2. The soil moves upward along the drill bit, reducing the traveling resistance of the powder ridge drill bit and the deep plowing and deep loos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com