A kind of fresh leaf silage booth green room

A technology of fresh leaves and silage storage, which is applied in tea treatment before extraction, etc., can solve problems such as increasing the difficulty of fresh leaves, increasing production labor, and improper atomization of spray water, so as to achieve flexible production time arrangement and improve product comprehensiveness Productivity, effects of slowing physical and chemical changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

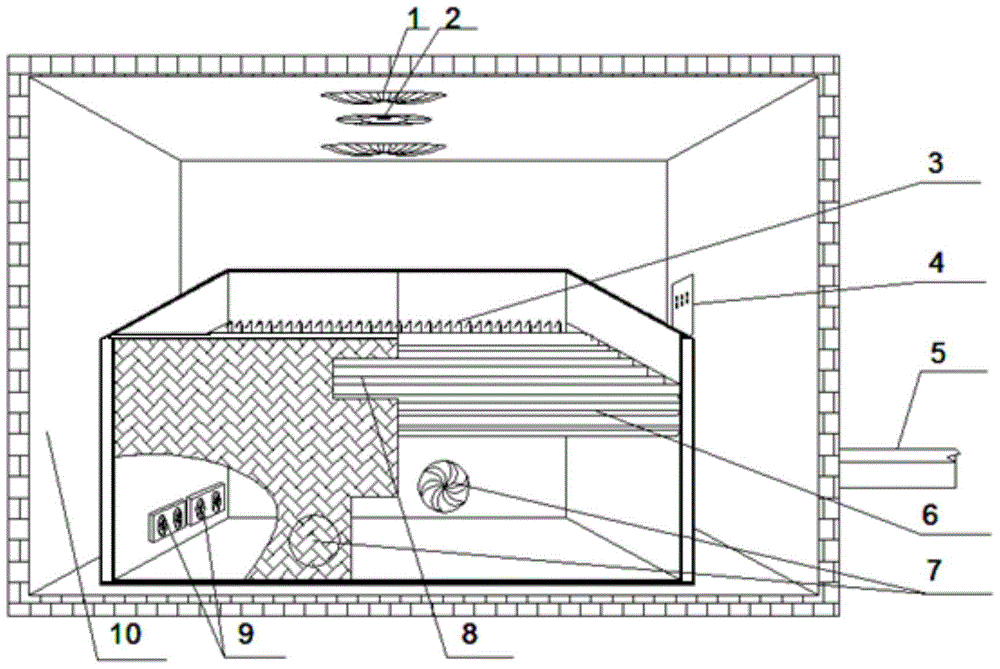

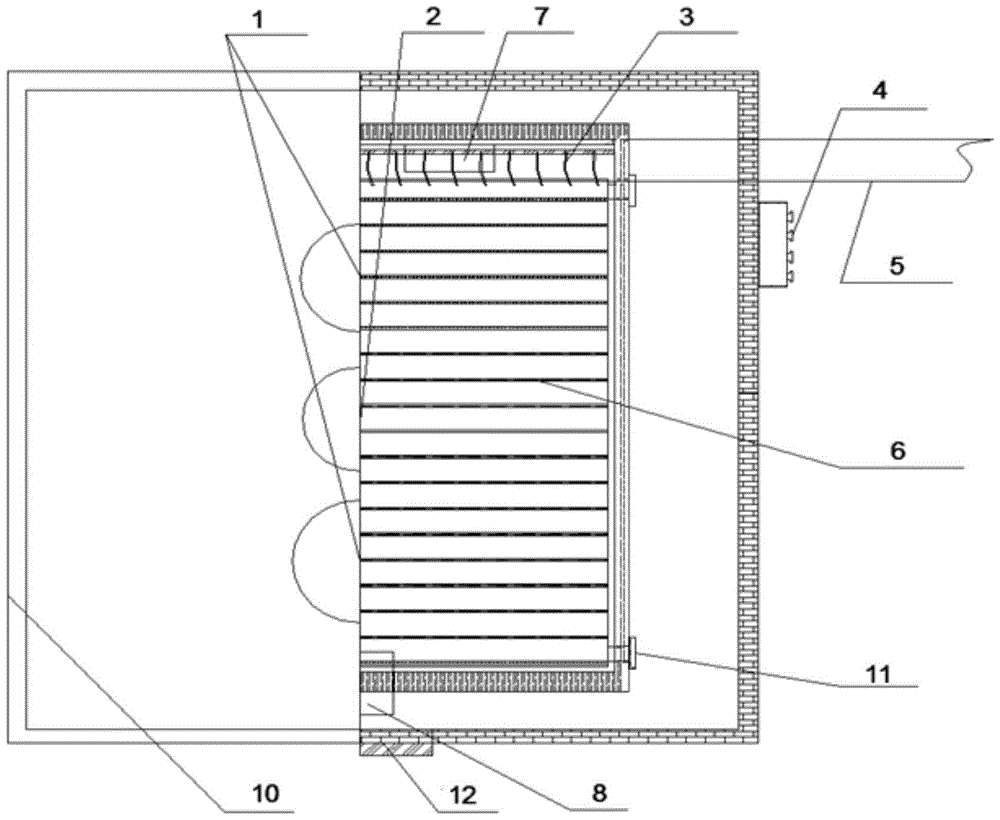

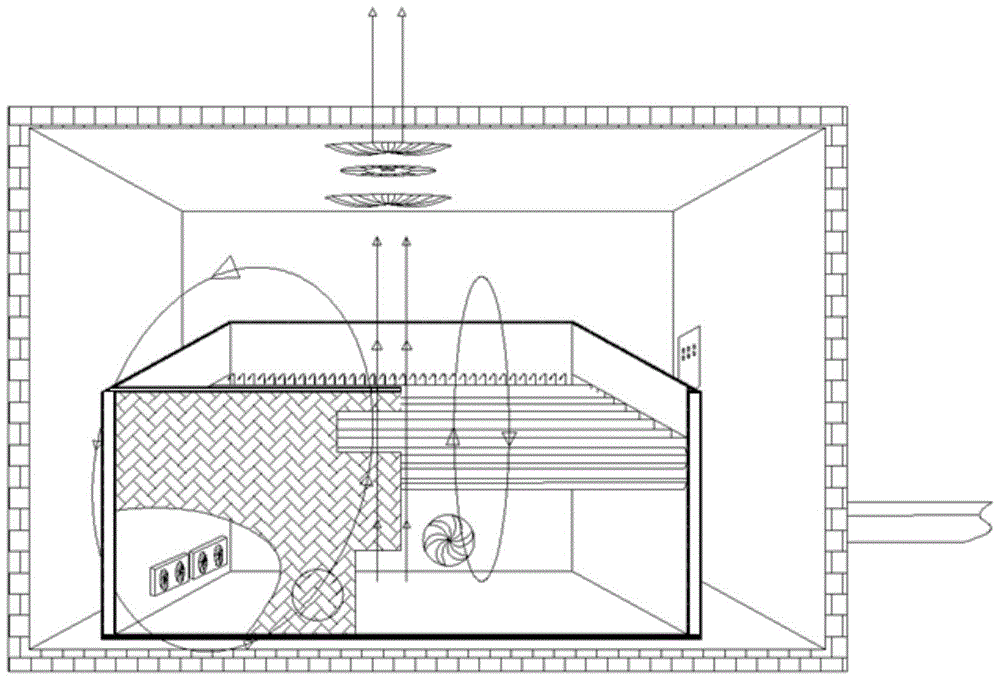

[0020] Embodiment 1: a kind of green room of fresh leaf storage green booth of the present invention, the warehouse body 10 of fresh leaf storage green booth green room is made of color steel insulation board, and the top of fresh leaf storage green booth green room is provided with exhaust fan 1 and Illumination lamp 2, a greening machine is arranged in the middle of the green room of the fresh leaf storage booth, a warehouse door 12 is arranged in front of the green room of the fresh leaf storage booth, and a control cabinet 4 and a vibration discharge chute 5 are arranged on the side of the green room of the fresh leaf storage booth , the vibrating discharge chute 5 is connected on the blue stand machine and stretches to the outdoor of the fresh leaf storage green stand; the control cabinet 4 is connected on the green stand machine to control its operation; Machine bottom, blower fan 7 is placed in the lower part of the side wall at the two ends of the green machine; 19 is ...

Embodiment 2

[0021]Embodiment 2: a kind of fresh leaf silage booth green room of the present invention, the warehouse body 10 of fresh leaf silage booth green room is made of stainless steel inner wall polyurethane insulation board, and fresh leaf silage booth top is provided with exhaust fan 1 and lighting lamp 2, a greening machine is arranged in the middle of the green room of the green leaf storage booth, a warehouse door 12 is arranged in front of the green room of the fresh leaf storage green room, and a control cabinet 4 and a vibration discharge chute are arranged on the side of the green room of the fresh leaf storage green room 5. The vibrating discharge chute 5 is connected on the green stand machine and stretches to the fresh leaf storage green stand outdoor; the control cabinet 4 is connected on the green stand machine to control its operation; the periphery of the green stand machine is provided with wall panels, and the cooling fan 9 is placed The bottom of the green machine,...

Embodiment 3

[0022] Embodiment 3: a kind of fresh leaf silage booth green room of the present invention, the warehouse body 10 of fresh leaf silage booth green room is made of stainless steel inner wall polyurethane insulation board, and fresh leaf silage booth top is provided with exhaust fan 1 and lighting lamp 2, a greening machine is arranged in the middle of the green room of the green leaf storage booth, a warehouse door 12 is arranged in front of the green room of the fresh leaf storage green room, and a control cabinet 4 and a vibration discharge chute are arranged on the side of the green room of the fresh leaf storage green room 5. The vibrating discharge chute 5 is connected on the green stand machine and stretches to the fresh leaf storage green stand outdoor; the control cabinet 4 is connected on the green stand machine to control its operation; the periphery of the green stand machine is provided with wall panels, and the cooling fan 9 is placed The bottom of the green machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com