Method for preparing flour-coated crispy food

A technology of breading and food, which is applied in the field of preparation of breaded crispy food, can solve the problems of uneven wrapping, long preparation time, high oil content, etc., and achieve the effects of precise temperature control, short frying time, and reduced oil content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

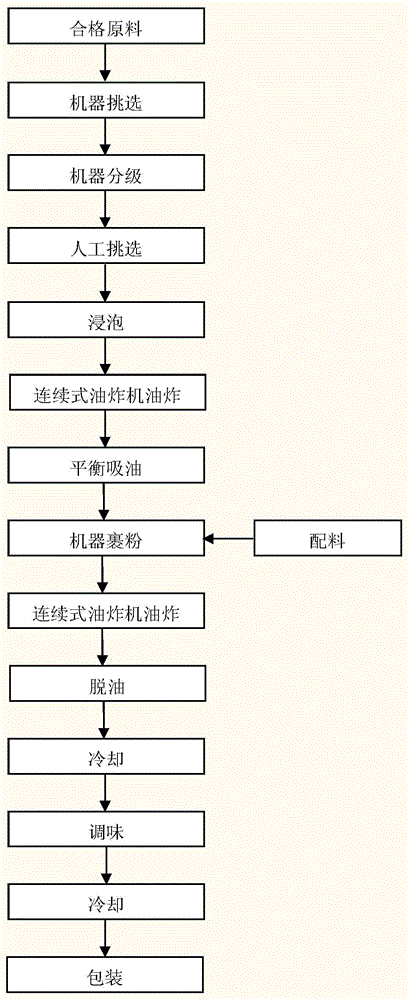

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1 crab roe and peanut food

[0023] (1) Select peanuts with full grains, no incomplete shape, and no rotten fruit, insect fruit or broken peanuts;

[0024] (2) Remove the peel wrapped on the surface of the selected peanuts, then soak them in water with a water temperature of 20°C for 15 hours, and then place them in an automatic fryer for frying. The frying temperature is controlled at 190°C. The frying time is controlled at 2-2.5min;

[0025] (3) Place the fried peanuts in step (2) in the air to automatically cool to 60°C, so that the water is fully diffused; then coat the peanuts for the first time; the ratio of the powder is: 4 parts of salt, 2 parts of monosodium glutamate , 40 parts of flour, 25 parts of starch, and 3 parts of sugar. Now dissolve sugar in water at a ratio of 3g:50ml to water to form sugar water, and stir and dissolve edible salt and monosodium glutamate into sugar water. Mix 40 parts of remaining flour and 25 parts of starch evenly to ...

Embodiment 2

[0029] Embodiment 2 Beef-flavored broad beans

[0030] The preparation steps are the same as in Example 1, except that 50KG of broad beans after being fried and cooled for the first time are selected for the first coating, other ingredients are: 2KG of sugar water (white sugar 1.16KG, water 0.81KG, edible salt 0.02KG , monosodium glutamate 0.01KG), mixed powder 2KG (flour 0.74KG, glutinous rice flour 0.74KG, modified starch 0.3KG, edible cornstarch 0.22KG). Spray and wrap the powder; add edible salt and monosodium glutamate to the sugar water to make the powder taste more delicious; add edible cornstarch and modified starch to the mixed powder to make the product more crispy.

[0031] The second powder coating is the seasoning step. In addition to the 15KG of broad beans (broad bean embryos) after deoiling and cooling, the main seasonings are: sprinkling mixed seasoning powder (such as commercially available spicy cumin seasoning powder) 0.3KG: sauce Juice beef powder 0.12KG,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com