Cylindrical grinding gantry manipulator

A technology of manipulator and cylindrical grinding, which is applied in the direction of grinding machine tool parts, grinding feed movement, grinding/polishing equipment, etc., which can solve the problems of rising labor costs and poor operating environment, and achieve the improvement of biological benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

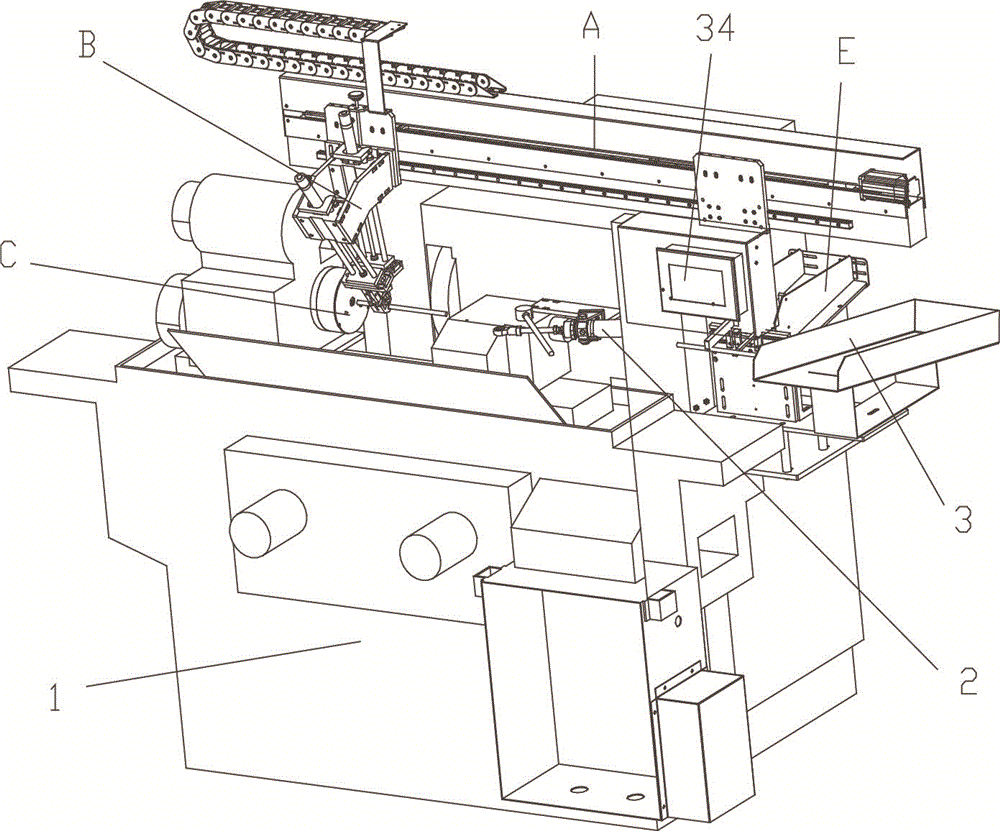

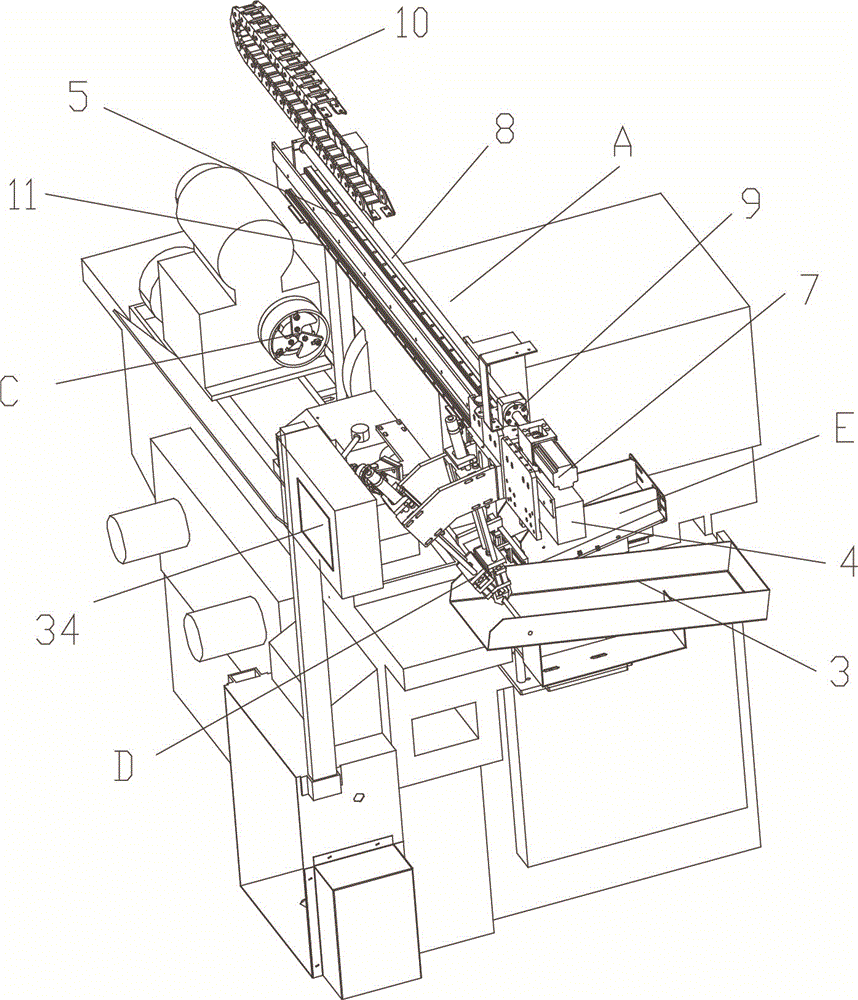

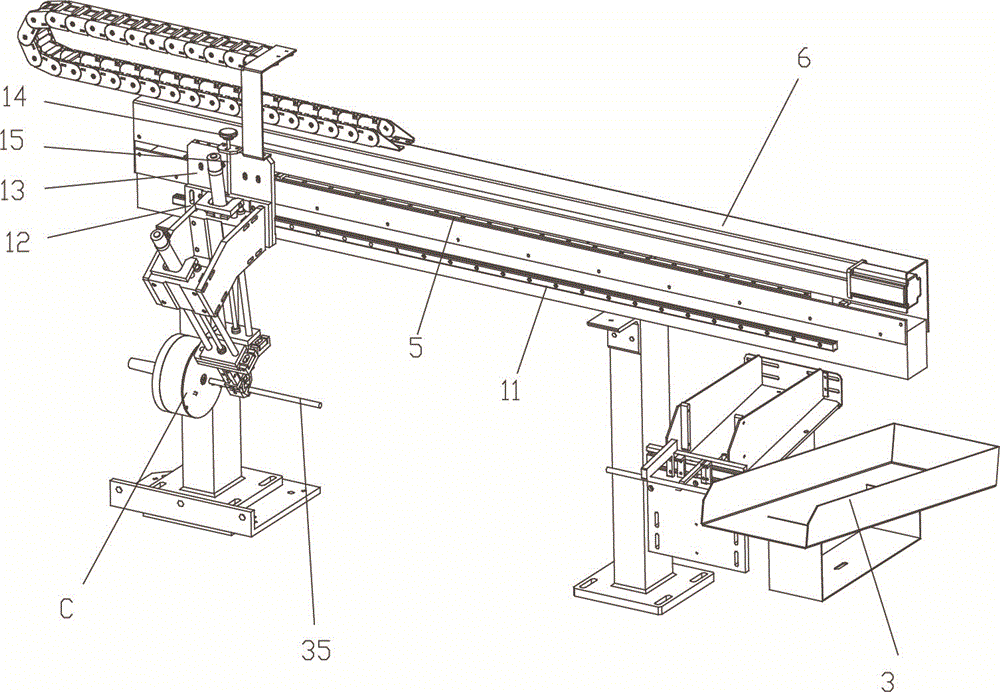

[0023] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1~8 As shown in the figure, the marks are as follows: moving beam A, clamping mechanism B, automatic chuck C, clamping hand D, feeding bin E, cylindrical grinder 1, tailstock cylinder 2, feeding bin 3, beam 4, middle slide rail 5. Beam cover 6, motor 7, screw rod 8, sliding table 9, towline 10, lateral slide rail 11, connecting plate 12, adjusting plate 13, adjusting handle 14, adjusting screw 15, fixed side plate 16, fixed cylinder Block 17, lifting cylinder 18, guide rod 19, guide plate 20, air claw 21, thimble 22, inner turntable 23, outer turntable 24, clamping plate 25, clamping arc-shaped surface 25a, rotating shaft 26, pulling out slide bar 27 , Material silo 28, bottom plate 28a, material distribution hole 28b, material pushing opening 28c, side plate 28d, material blocking block 28e, material silo cylinder 29, material di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com