Automotive lighting cover component

A technology of automotive lighting, cover assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

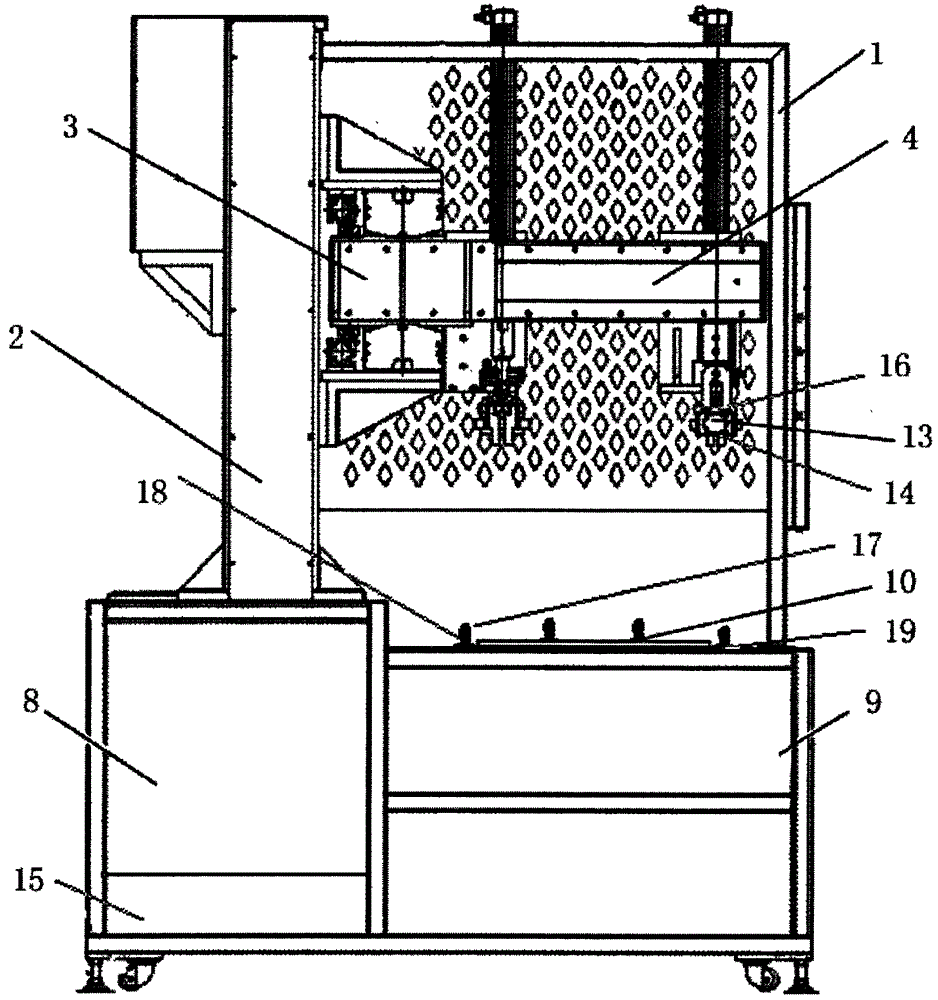

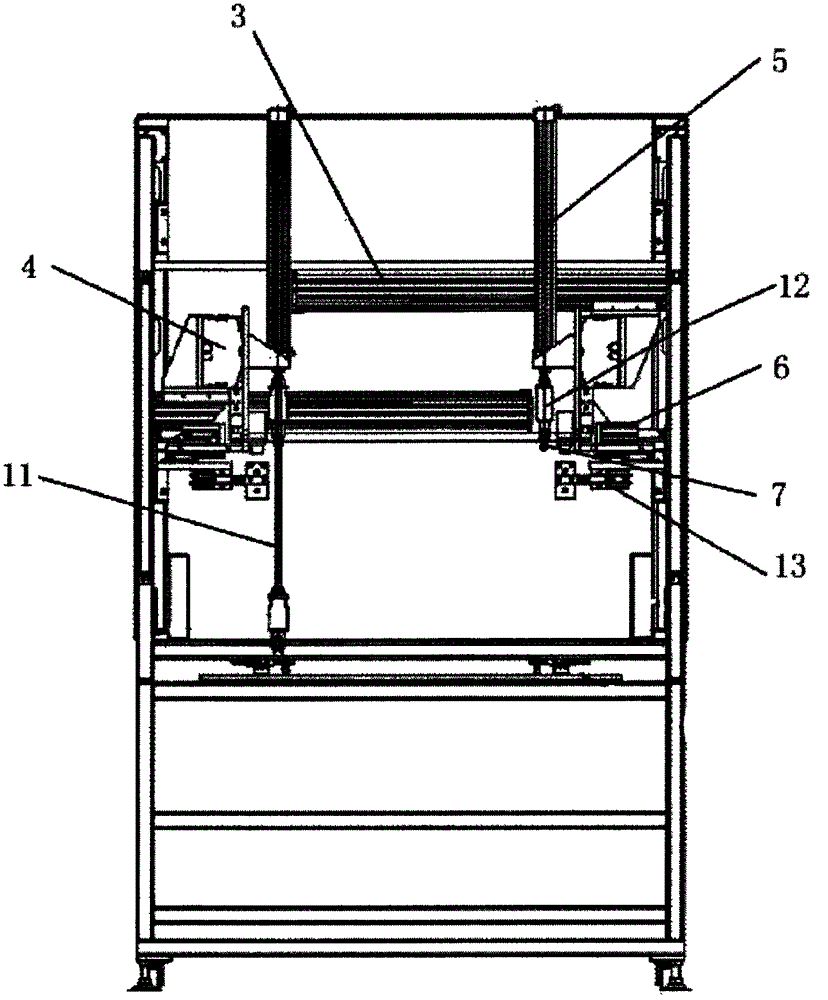

[0017] See figure 1 and figure 2 As shown, an automobile lighting lamp cover assembly includes a frame 1; a slide table column 2 is provided at one end of the frame 1, and an X-axis slide table 3 is arranged laterally on the slide table column 2. The X-axis slide table 3 is provided with a Y-axis slide table 4 for supporting the thermally buried cylinder 5, and the outside of the thermally buried cylinder 5 is equipped with a vertical feeding mechanism 6 that automatically provides screws. Sensor 7, the feeding sensor 7 is connected to the PLC through a signal, the top of the thermal buried pneumatic rod 11 is provided with a screw suction head 12 for sucking up the bolt and a chuck 13 for clamping the bolt, located at the chuck 13 A proximity sensor 14 is connected directly below the working base 10, and a positioning device 17 is arranged on the working base 10, and the positioning device 17 is a diamond-shaped pin 18 and a circular pin 19 distributed diagonally. The slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com