Carbon fiber sandwich gauge framework and manufacturing method thereof

A technology of carbon fiber and carbon fiber plate, which is applied in the field of carbon fiber sandwich inspection tool frame and its preparation, can solve the problems of long production cycle, increased cost, complicated process, etc., and achieve the effect of weight reduction, convenient processing and low process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation of the present invention will be described in detail below in conjunction with examples. It should be understood that the examples are provided to illustrate the invention and not to limit the invention. The scope and essential content of the present invention are defined by the claims.

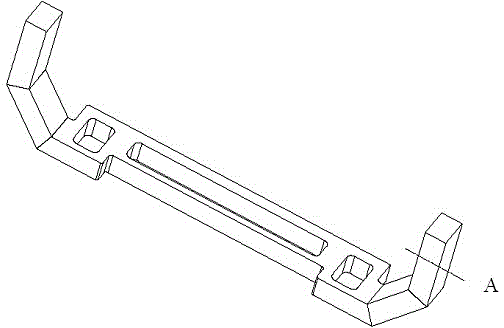

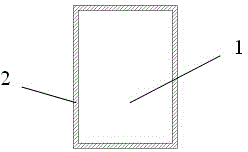

[0022] The carbon fiber sandwich inspection tool of the present invention is composed of an inner foam core 1 and a carbon fiber plate wrapped on the inner foam core 1. The carbon fiber plate is divided into small pieces of different shapes according to the shape of the product and then pasted on the On the inner foam core 1.

[0023] The specific preparation method of the carbon fiber sandwich inspection tool of the present invention is:

[0024] 1. According to the split theory design, the foam block is cut into the required shape according to the product requirements to obtain the foam preform.

[0025] 2. Forming carbon fiber board, the process is:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com