A process of UV image printing on a surface layer of a respiratory type mouth mask

A printing image, breathing type technology, applied in the direction of printing, copying/marking methods, etc., can solve the problems that no one chooses UV printing technology for protective masks, is not suitable for printing of breathing type masks, and cannot control the position of pictures, etc., and achieves color fastness Good, not easy to fade, simple process operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0012] Taking a breathing mask made of polypropylene non-woven fabric as an example, a UV printing process on the surface of the breathing mask of the present invention is described. When printing UV images, the following steps are included:

[0013] (1) Computer graphics: use computer software to draw the pattern that needs to be printed on the surface of the breathing mask, and adjust the size and proportion of the printed pattern according to the size of the breathing mask;

[0014] (2) Mold fixing: place the breathing mask in the mold, ensure that the mask is placed flat in the groove of the mold, and ensure that the image is printed at the correct position on the surface of the mask;

[0015] (3) UV printing: use a UV printer to print images on the breathing mask;

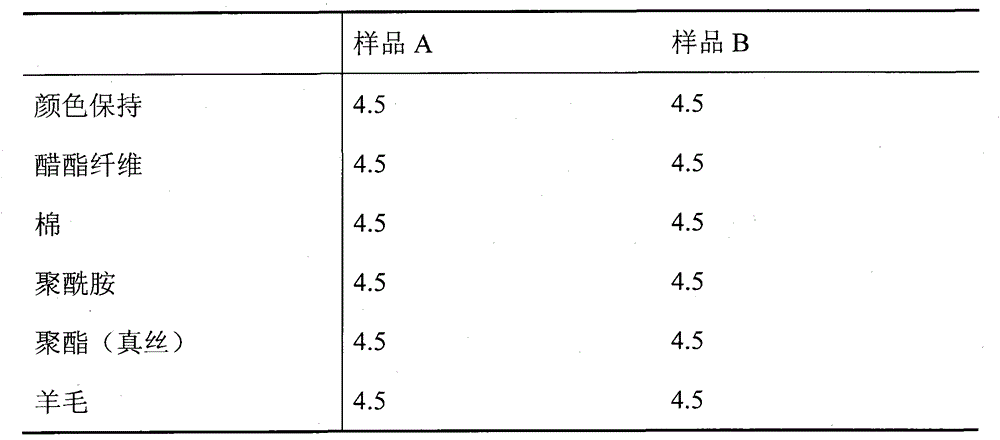

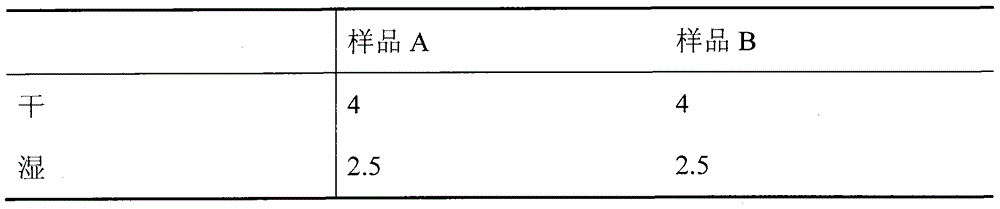

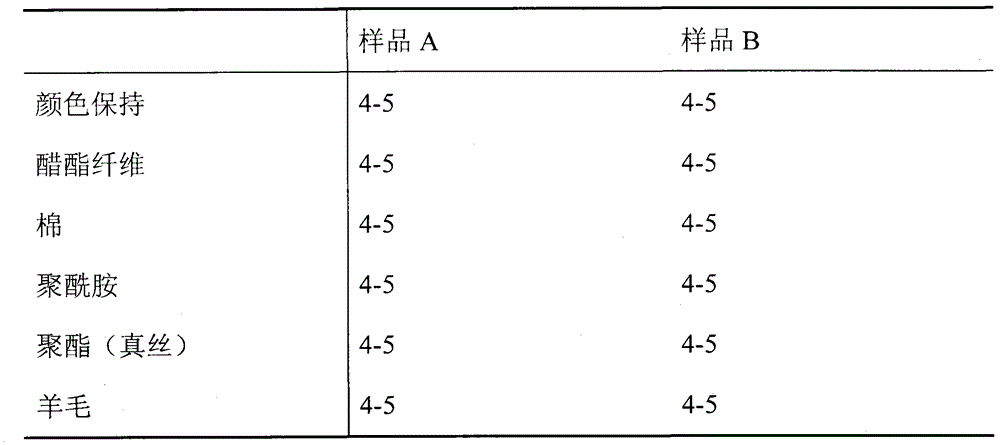

[0016] With the patterned polypropylene non-woven mask prepared through the above steps, we carried out the color fastness test and the volatile organic compound test respectively as follows:

[0017] 1. Col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com