Continuously variable transmission and bicycle with the same

A technology of continuously variable transmissions and bicycles, which is applied to vehicle gearboxes, vehicle components, chain/belt transmissions, etc., and can solve problems such as the need for further improvement in stability and reliability, complex installation structure of transmissions, and unclosed transmission systems, etc. Achieve the effect of simple structure, convenient installation and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

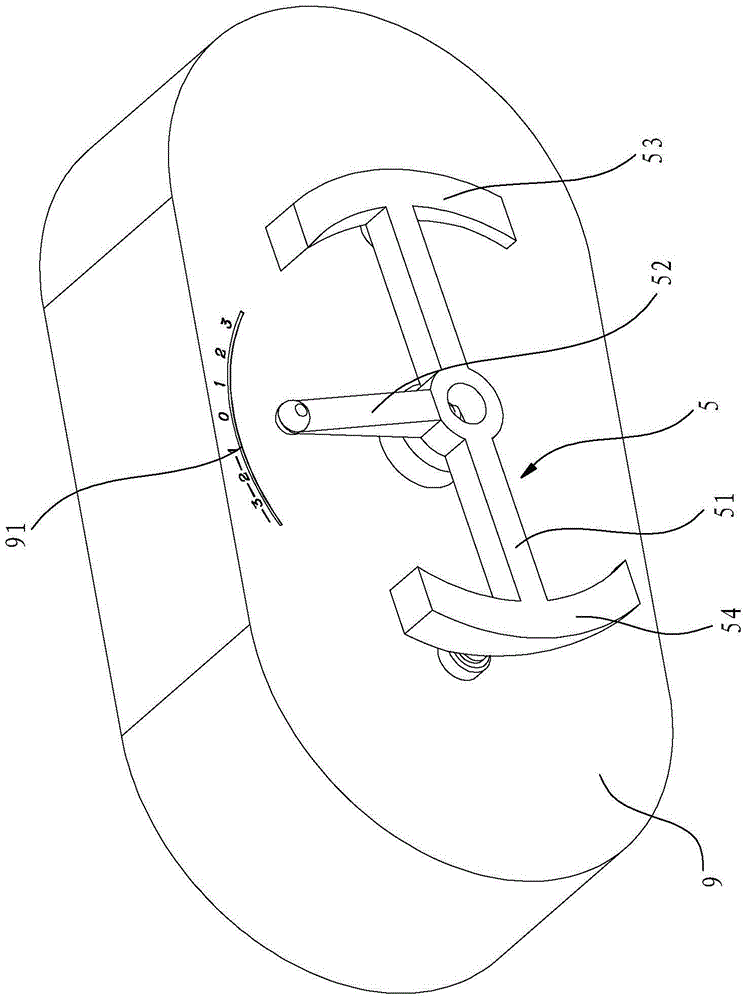

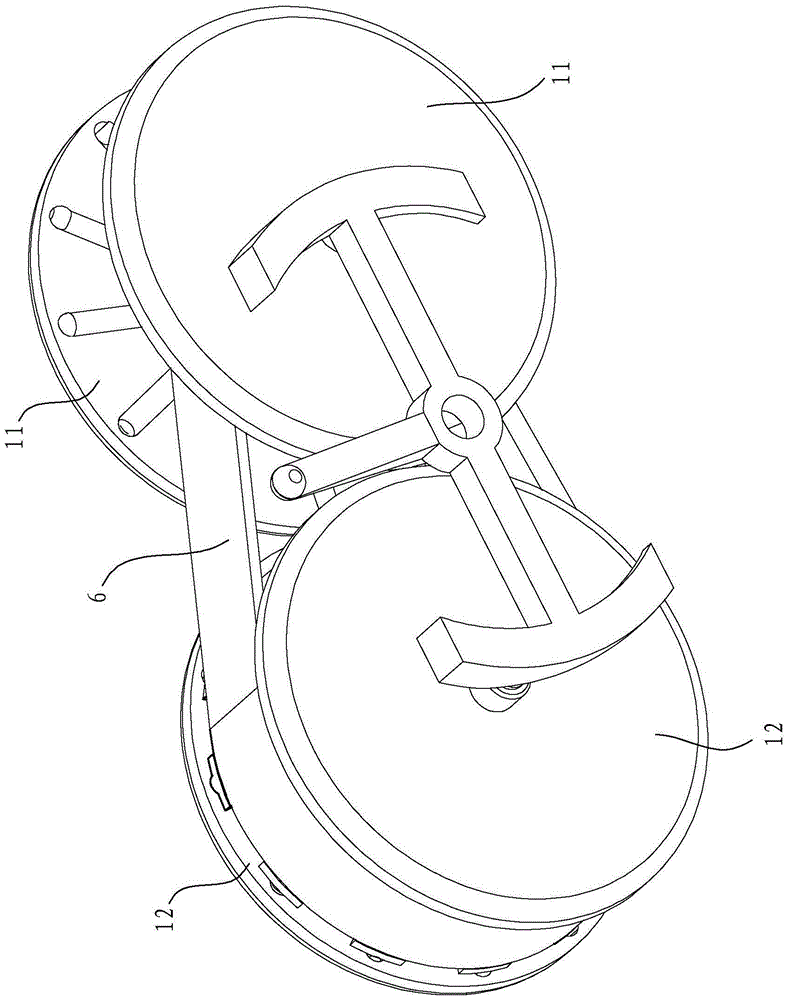

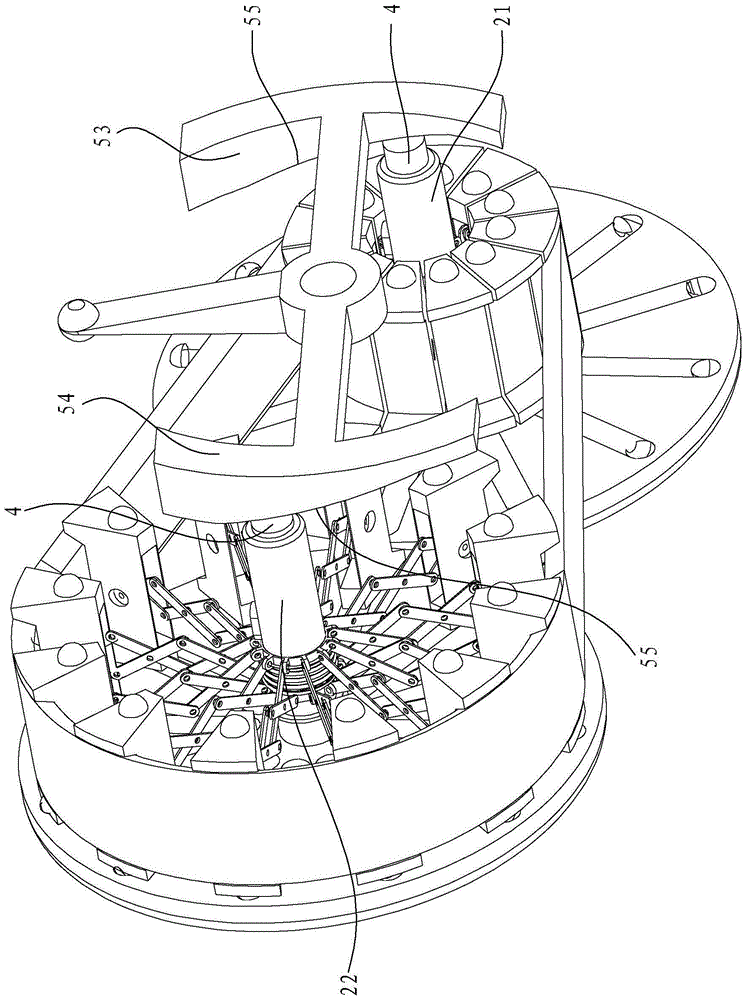

[0047] Such as Figure 1 to Figure 8 As shown, the continuously variable transmission in this embodiment includes a housing 9, a driving disc 11, a driven disc 12, a first mounting shaft 21, a second mounting shaft 22, a first slider group 31, and a second slider group 32 , the first connecting piece, the second connecting piece, the pin shaft 4, the trigger link 5, the transmission belt 6, the spring 7 and other main components. The driving disc 11 and the driven disc 12 are all located in the housing 9, the driving disc 11 is adjacent to the driven disc 12, the first mounting shaft 21 is the driving shaft and is installed in the center of the driving disc 11, and the second mounting shaft 22 is connected to the driving disc 11. The drive shaft is also installed in the center of the driven disk 12 , the first installation shaft 21 and the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com