A kind of preparation method of high-refractive-index high-transparency frictional silica

A silicon dioxide, refractive index technology, applied in the direction of silicon dioxide, silicon oxide, etc., can solve the problem of no effective solution, no specific disclosure of refractive index, transparency, transparency, etc., to reduce the interface free energy and transparency. Enhanced, uniform particle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

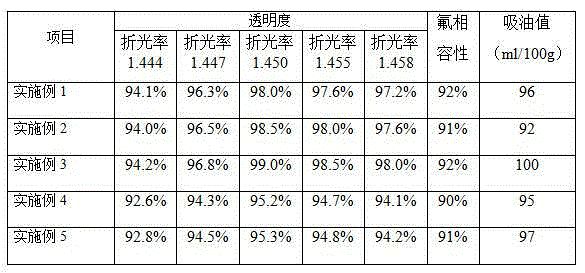

Examples

Embodiment 1

[0029] A method for preparing high-refractive-index high-transparency friction-type silica, comprising the following steps:

[0030] (1) The deployment concentration is 2.0M sodium silicate solution 10m 3 , add 1.0kg surfactant, stir evenly, described surfactant is the mixture that sodium lauryl sulfate and sodium laureth sulfate mix with weight ratio 1:1;

[0031] (2) Inject 10m of 2.5% sodium sulfate solution into the reaction tank 3 , turn on the stirring device and heat to 80°C;

[0032] (3) Add sodium silicate solution to the reaction tank at a flow rate of 12m3 / h, add sulfuric acid solution at the same time after 0.5min, control the pH value at 9.0, continue to add sulfuric acid solution after adding the sodium silicate solution to control the pH value at the end of the reaction When the temperature is 4.4, stop adding the sulfuric acid solution, keep the temperature at 80°C, and continue to stir and sink for 10 minutes to obtain a slurry;

[0033] (4) Press filter th...

Embodiment 2

[0035] A method for preparing high-refractive-index high-transparency friction-type silica, comprising the following steps:

[0036] (1) The deployment concentration is 2.5M sodium silicate solution 13m 3 , add 2.0kg of surfactant and stir evenly, the surfactant is a mixture obtained by mixing sodium lauryl sulfate and polyethylene glycol (600) dilaurate at a weight ratio of 1:1;

[0037] (2) Inject 10m of 4.5% sodium sulfate solution into the reaction tank 3 , turn on the stirring device and heat to 90°C;

[0038] (3) Add sodium silicate solution to the reaction tank at a flow rate of 16m3 / h, add sulfuric acid solution at the same time after 1min, control the pH value at 9.5, continue to add sulfuric acid solution after adding the sodium silicate solution to control the pH value at the end of the reaction 4.8, stop adding sulfuric acid solution, keep the temperature at 85°C, continue stirring and sinking for 15 minutes to obtain slurry;

[0039] (4) Press filter the slurry...

Embodiment 3

[0041] A method for preparing high-refractive-index high-transparency friction-type silica, comprising the following steps:

[0042] (1) The deployment concentration is 2.3M sodium silicate solution 11m 3 , add 1.5kg surfactant, stir, and described surfactant is the mixture that cocamidopropyl amine oxide and sodium lauryl sulfate mix with weight ratio 1:1.5;

[0043] (2) Inject 10m of 3.5% sodium sulfate solution into the reaction tank 3 , turn on the stirring device and heat to 85°C;

[0044] (3) Add sodium silicate solution to the reaction tank at a flow rate of 14m3 / h, add sulfuric acid solution at the same time after 0.5min, control the pH value at 9.3, continue to add sulfuric acid solution after adding the sodium silicate solution to control the pH value at the end of the reaction When the temperature is 4.5, stop adding the sulfuric acid solution, keep the temperature at 85°C, and continue to stir and sink for 10 minutes to obtain a slurry;

[0045] (4) Press filter t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| cloud point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com