Ammonia recovery system for high ammonia nitrogen wastewater treatment

A wastewater treatment and ammonia recovery technology, applied in the high ammonia nitrogen wastewater treatment ammonia recovery system, ammonia nitrogen wastewater treatment process field, can solve the problems of impossible conversion, high construction cost, harsh operating conditions, etc., to achieve operating conditions and reasonable construction costs , the effect of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

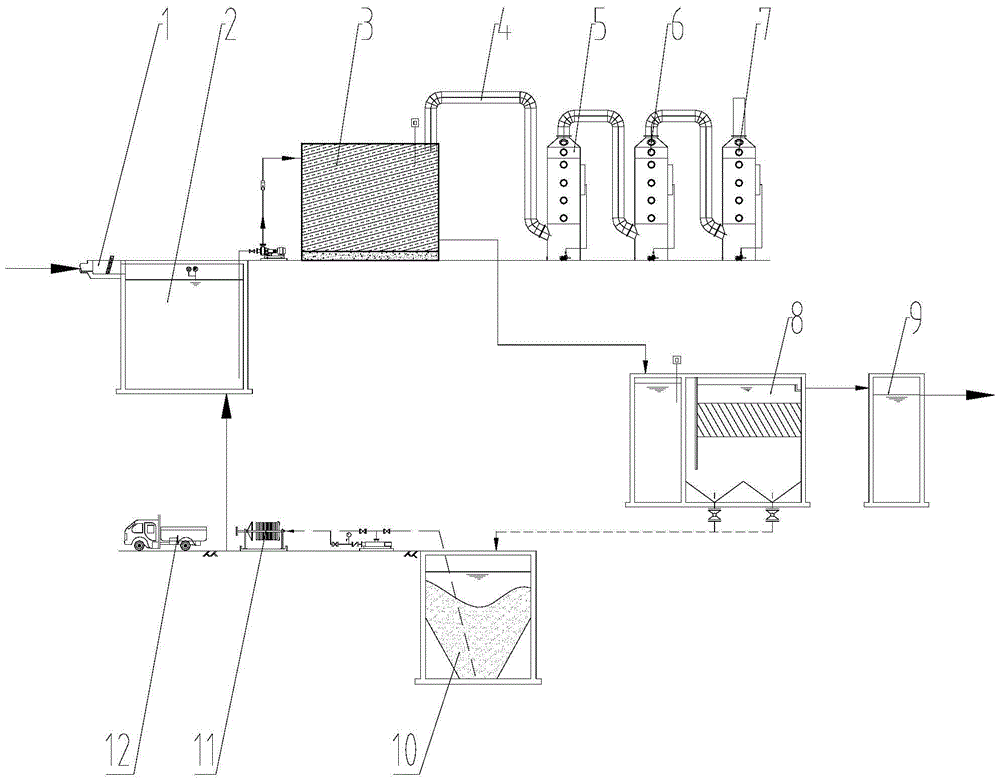

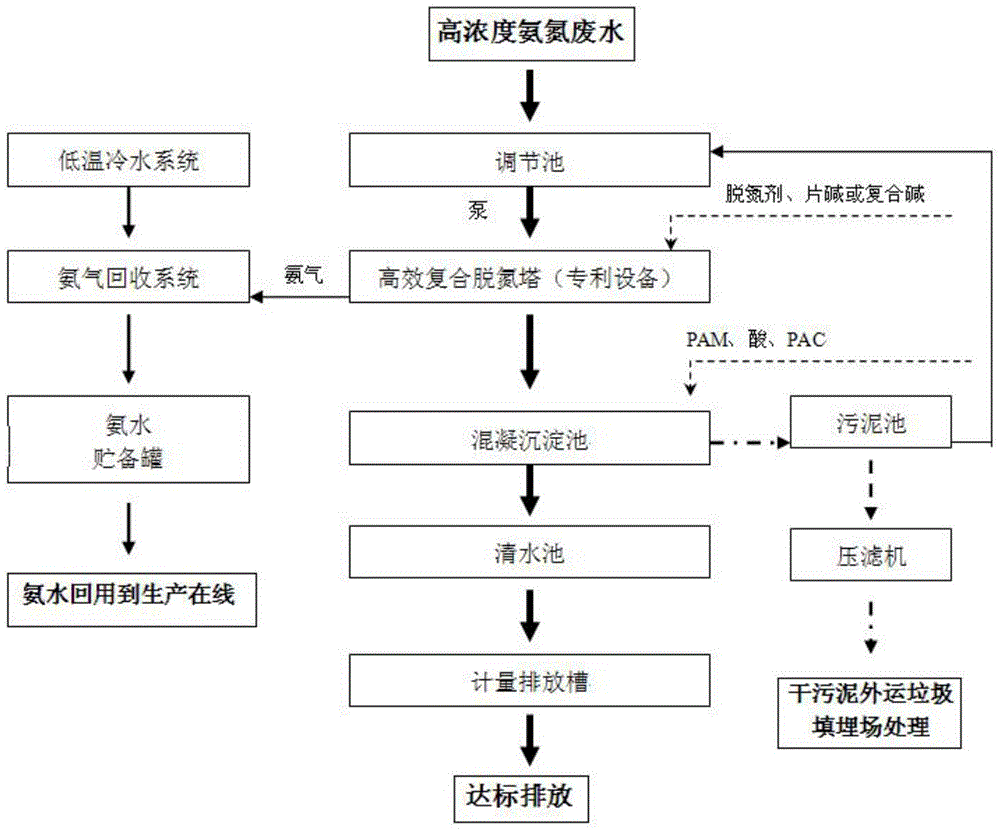

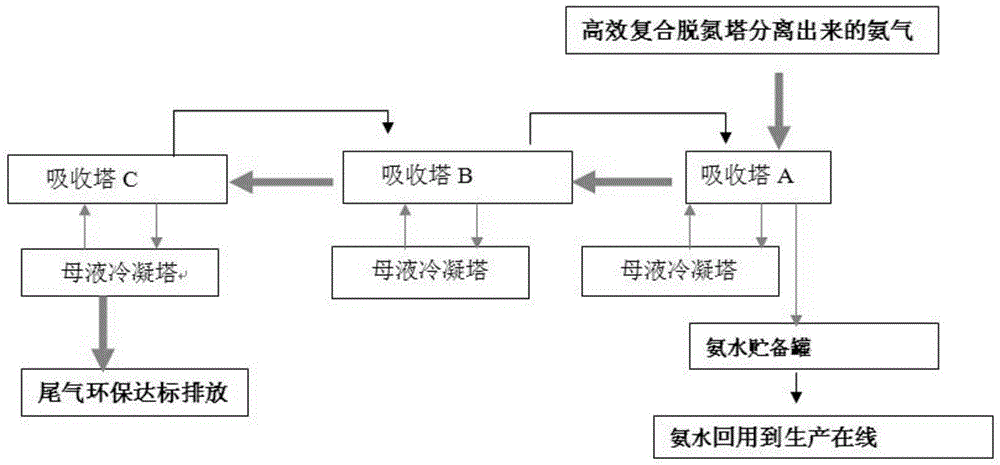

[0030] This embodiment provides an ammonia recovery system for high ammonia nitrogen wastewater treatment, the structure is as follows figure 1 As shown, it includes a waste water inlet 1, a pipeline 4, an absorption tower, a coagulation sedimentation tank 8, a sludge tank 10, a box filter press 11 and a mud cake export port 12, and the waste water inlet 1 leads to a regulating tank 2, and the regulating tank 2 is connected to the high-efficiency composite denitrification tower 3 through a pump, and the ammonia gas separated by the high-efficiency composite denitrification tower 3 enters the absorption tower through the upper pipeline 4; 8 is divided into a reaction pool and a separation pool. Coagulant is added to the reaction pool, and the clear water separated from the upper layer of the separation pool is introduced into the clear water pool 9, and discharged after the final test is up to standard. The turbid liquid separated from the lower layer of the separation pool ente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com