Oil field sewage treatment device

A technology for treatment device and oilfield sewage, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, centrifugal separation water/sewage treatment, etc. It has the advantages of ingenious design, simple structure and reduced impurity content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

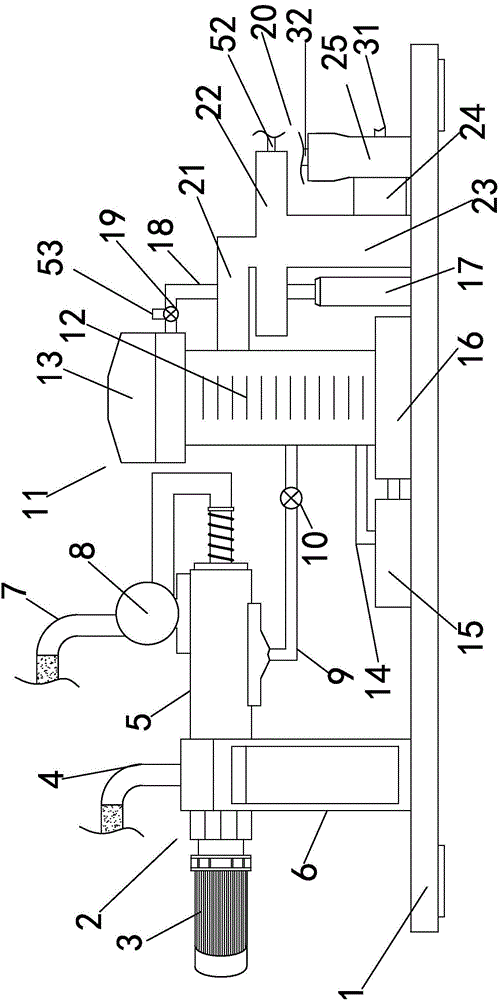

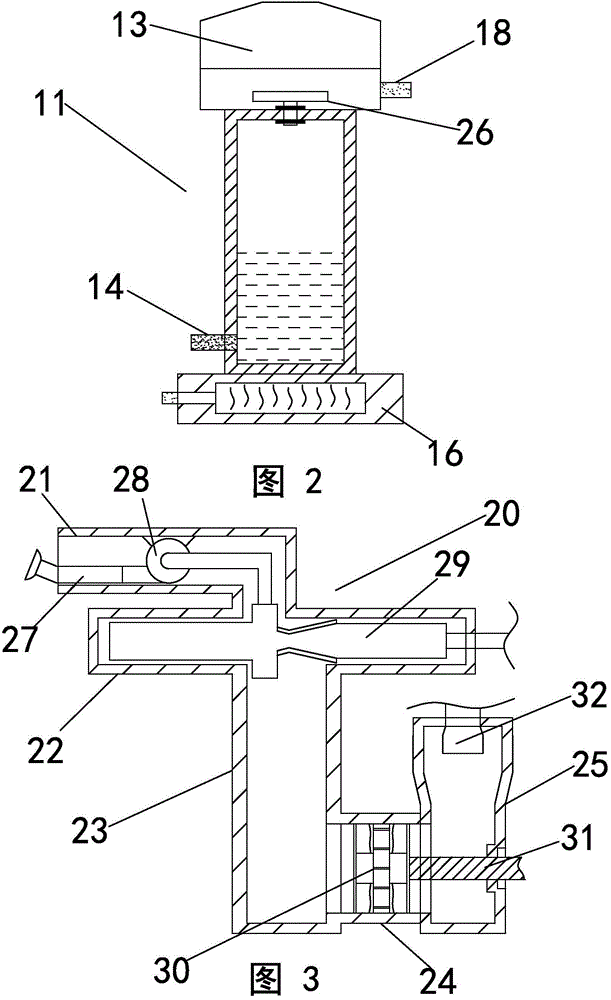

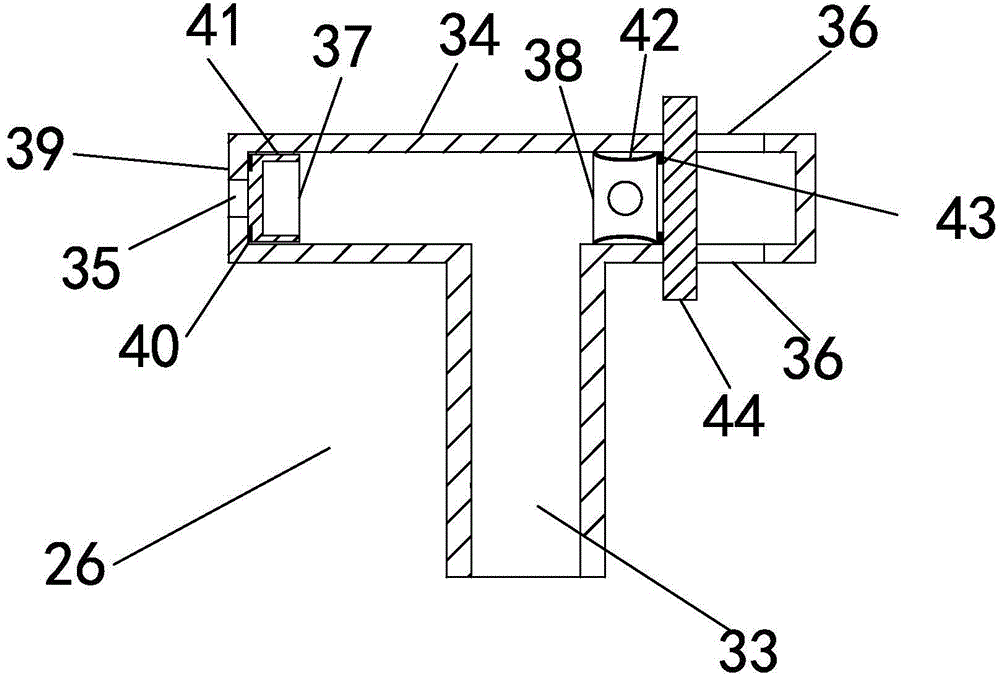

[0029] Such as figure 1 middle Figure 8As shown, an oilfield sewage treatment device is composed of a horizontal centrifuge 2 , a primary separation device 11 , a secondary separation device 20 and a base 1 . The base 1 is fixed on the ground and is used to support the horizontal centrifuge 2 , the primary separation device 11 and the secondary separation device 20 to obtain excellent stability. The lower end of the horizontal centrifugal separator 2 is connected with a connecting seat 6, and the connecting seat 6 is used for connecting the base 1, so that the stability of the horizontal centrifugal separator 2 is good. The horizontal centrifugal separator 2 includes a motor 3 and a centrifugal separator 5. The motor 3 is connected to the centrifugal separator 5. The operation of the motor 3 can drive the centrifugal separator 5 to move at high speed, so that the materials in the centrifugal separator 5 can obtain centrifugal force. The upper end of the centrifugal separato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com