Device for treating high-concentration pectin wastewater in processing canned citrus petals

A technology for pectin wastewater and treatment devices, which is applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of difficulty and high cost of bacterial strain cultivation, and improve solid Liquid separation effect, improvement of reaction effect, improvement of separation and removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

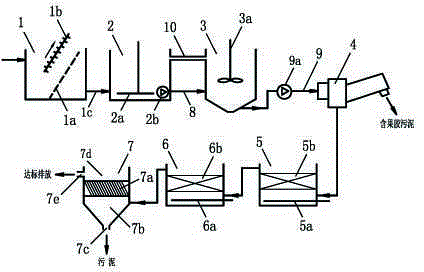

[0024] See attached picture. It includes a grid tank 1 and an aeration regulating tank 2, and the grid tank communicates with the aeration regulating tank through a component 1c; the grid tank 1 is provided with a mechanical grid 1a for filtering out suspended pollutants such as orange peel and orange network ; The aeration regulating tank 2 is provided with a first perforated aeration pipe 2a, which agitates the waste water pneumatically to achieve uniform and homogeneous treatment. In the grid pool 1, the suspended matter such as orange peel and orange network is filtered out by the mechanical grid 1a. The mechanical slag discharge mechanism 1b is arranged in the grid pool 1 of the present invention. type slag discharge mechanism.

[0025] There are reaction sedimentation tank 3, snail sludge dehydration device 4, hydrolytic acidification tank 5, biological contact oxidation tank 6 and sedimentation tank 7;

[0026] The aeration regulating tank 2 is provided with a first p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com