A kind of sealing structure of glass and metal and preparation method thereof

A bonding structure and glass technology, applied in the field of materials, can solve the problems of high wall thickness reduction, high expansion coefficient, high labor cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The glass and metal sealing structure of the present embodiment, its preparation method comprises the following steps:

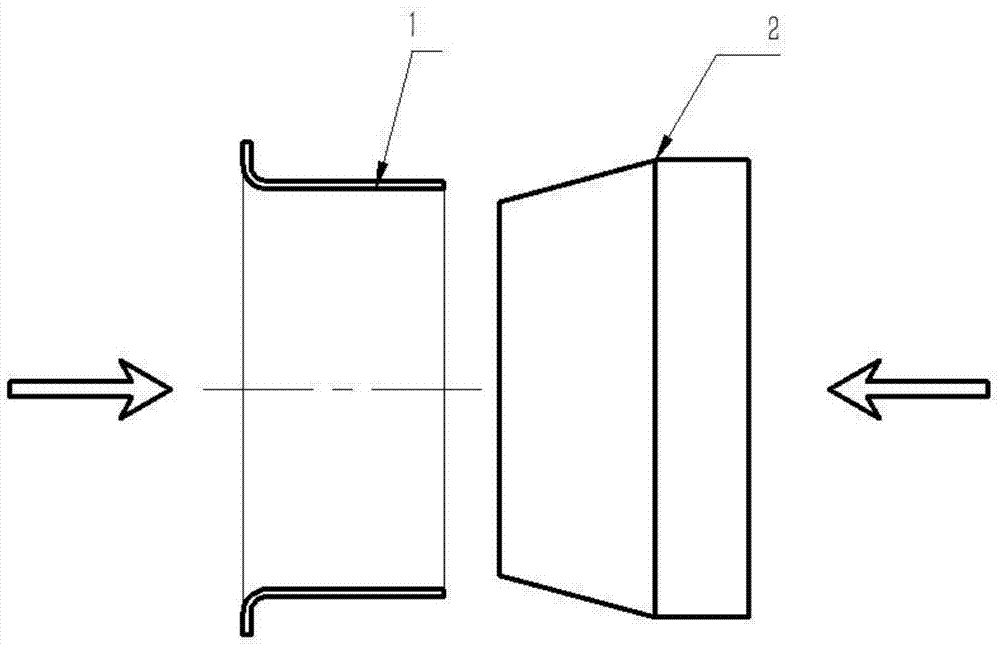

[0031] 1) Install the end of the ferritic stainless steel ring 1 to be sealed with the glass on the tapered expansion mold 2, such as figure 1 shown.

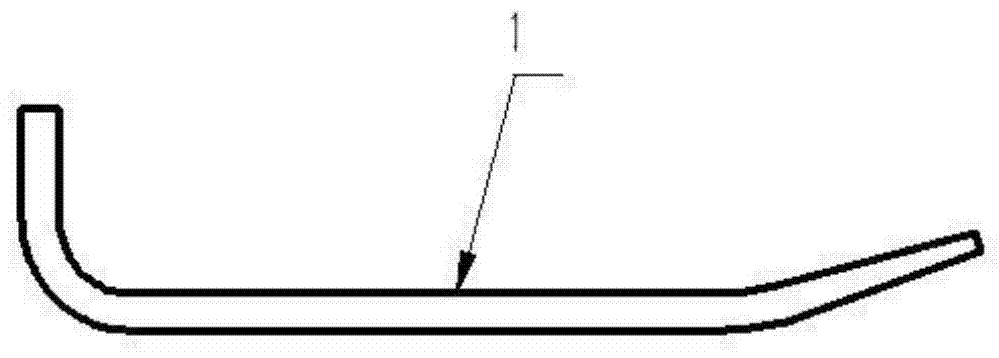

[0032] 2) Push the stainless steel ring 1 toward the tire mold 2 to expand the end, such as figure 2 shown.

[0033] 3) The end of the ferritic stainless steel ring 1 to be sealed with the glass is processed by CNC to an inclination angle of 3°.

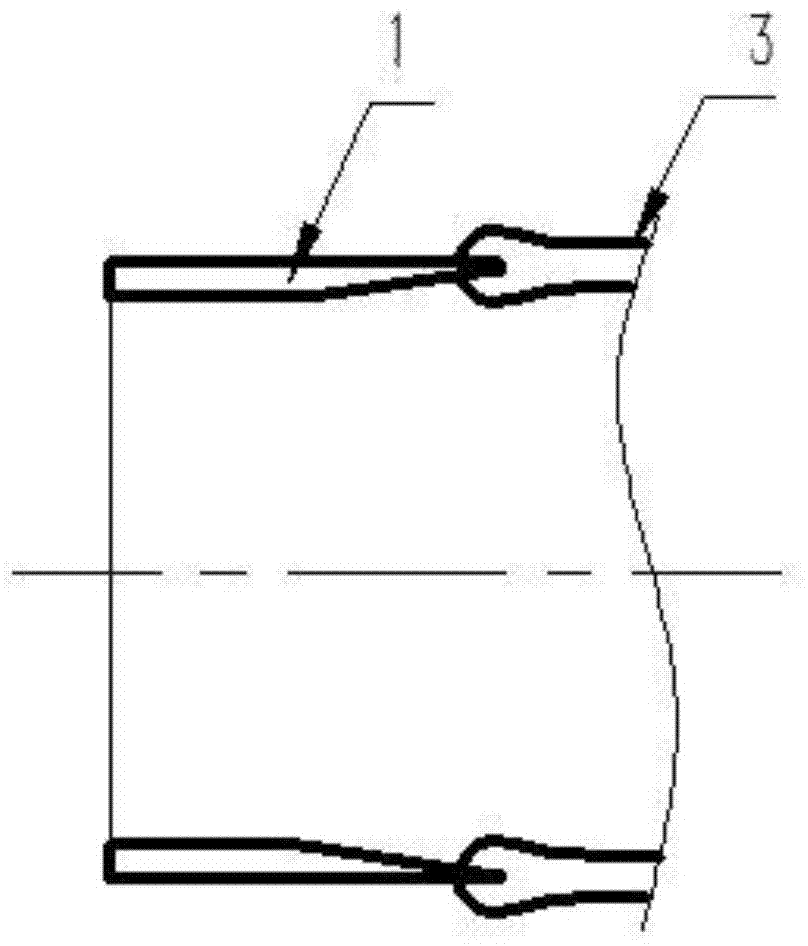

[0034] 4) Seal the stainless steel ring 1 prepared in the above steps and the glass 3 (refer to image 3 shown). The specific method of sealing is:

[0035] a) The metal is oxidized in a wet hydrogen furnace at a temperature between 800 and 1200°C. At this temperature, the wet hydrogen forms an oxide layer on the surface of the metal ring, which facilitates the bonding between the glass and the metal.

[0036] b) Sealing is carried out at high tempera...

Embodiment 2

[0041] The preparation method of the sealing structure of glass and metal in this embodiment comprises the following steps:

[0042] 1) Install the end of the ferritic stainless steel ring 1 to be sealed with the glass on the tapered expansion mold 2, as figure 1 shown.

[0043] 2) Push the stainless steel ring 1 toward the tire mold 2 to expand the end, such as figure 2 shown.

[0044] 3) The end of the ferritic stainless steel ring 1 to be sealed with the glass is processed by CNC to an inclination angle of 2°.

[0045] 4) Seal the stainless steel ring 1 prepared in the above steps with the glass, such as image 3 shown. The specific sealing method is the same as that in Embodiment 1.

[0046] In this embodiment, the expansion coefficient of the glass tube is 3.4×10 -6 m / (m.K), the expansion coefficient of ferritic stainless steel is 12×10 -6 m / (m.K). The chemical composition of the glass tube is (all mass fractions): 85% silicon oxide, 10% boron oxide, 2% sodium ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com