Waterproof high polymer easy plaster

A polymer and Yijiao technology, applied in the field of building materials, can solve the problems of insufficient strength and poor waterproof performance of Yijiao

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

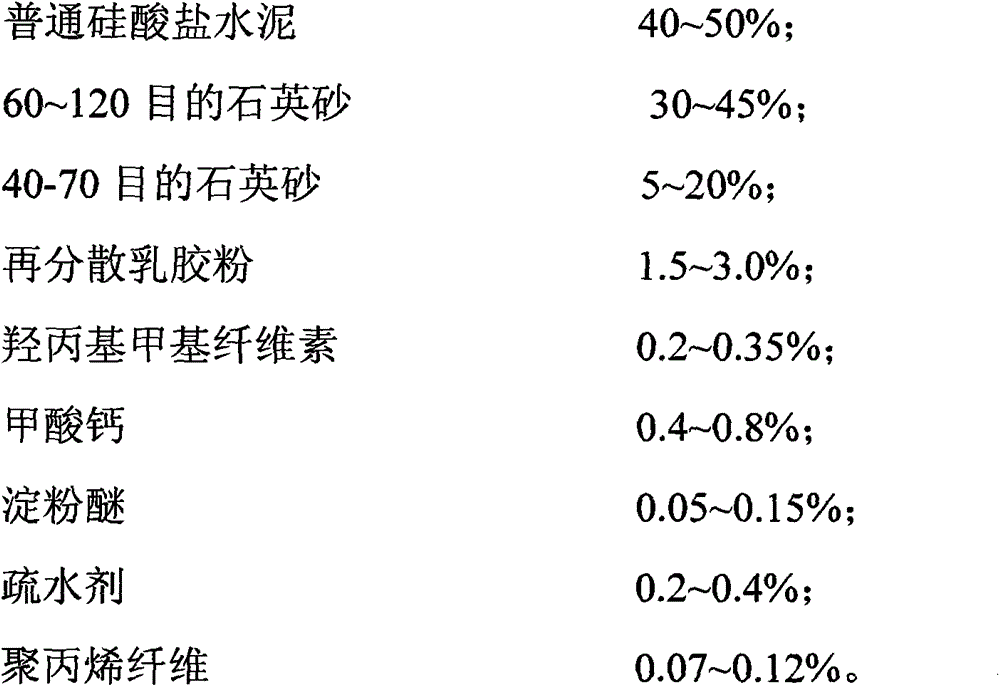

[0019] Ordinary Portland cement 40%; quartz sand with a particle size of 60-120 mesh accounts for 42.5%, quartz sand with a particle size of 40-70 mesh accounts for 13.58%; redispersed latex powder 2.5%; hydroxypropyl methylcellulose 0.35%; Calcium formate 0.5%; starch ether 0.15%; hydrophobic agent 0.35%; polypropylene fiber 0.07%.

[0020] Its test data is as follows:

[0021]

Embodiment 2

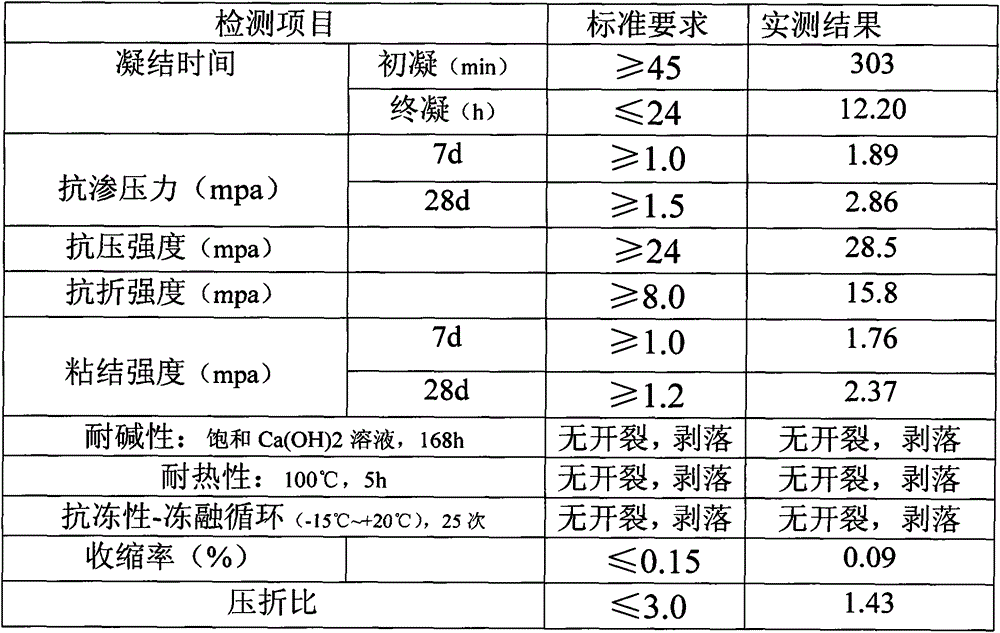

[0023] Ordinary Portland cement 45%; quartz sand with a particle size of 60-120 mesh accounts for 43%, quartz sand with a particle size of 40-70 mesh accounts for 7.7%; redispersed latex powder 2.8%; hydroxypropyl methylcellulose 0.25%; Calcium formate 0.75%; starch ether 0.1%; hydrophobic agent 0.3%; polypropylene fiber 0.1%.

[0024] Its test data is as follows:

[0025]

Embodiment 3

[0027] Ordinary Portland cement 44%; quartz sand with a particle size of 60-120 mesh accounts for 40.63%, and quartz sand with a particle size of 40-70 mesh accounts for 12%; redispersed latex powder 1.8%; hydroxypropyl methylcellulose 0.3%; Calcium formate 0.8%; Starch ether 0.05%; Hydrophobic agent 0.3%; Polypropylene fiber 0.12%

[0028] Its test data is as follows:

[0029]

[0030]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com