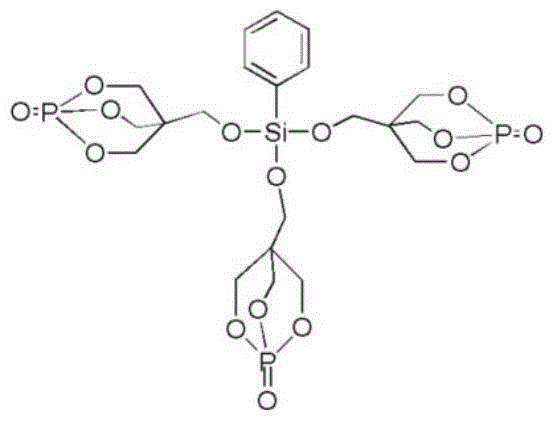

Bicyclic caged phenyl phosphate silicone modified flame-retardant PC/ABS (polycarbonate/acrylnitrile-butadiene-styrene) alloy and preparation method thereof

A technology of phosphate ester siloxane and alloy materials, applied in flame retardant polycarbonate/styrene-butadiene-acrylonitrile copolymer alloy materials, double-ring cage phosphate ester siloxane flame retardant PC/ABS alloy materials In the field of its preparation, it can solve the problems of reducing heat distortion temperature and fluidity, and achieve the effects of excellent mechanical properties, good processing fluidity, and high flame retardant grade.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

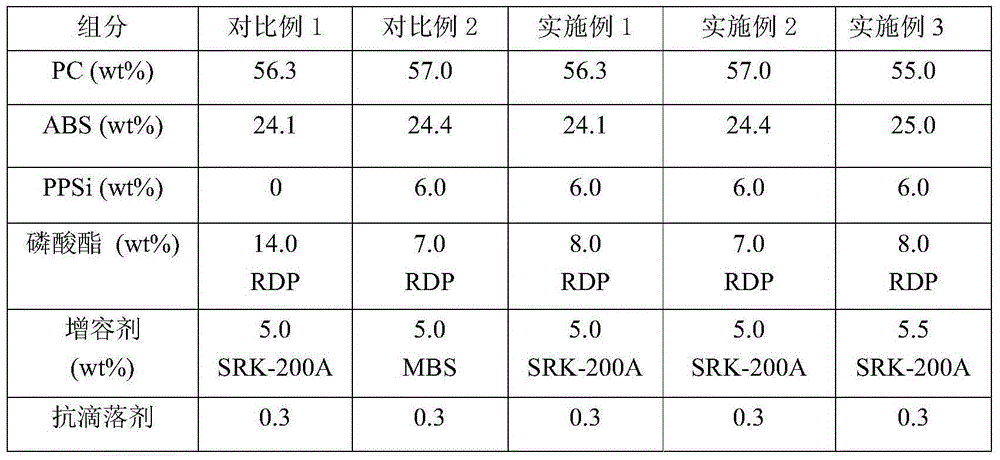

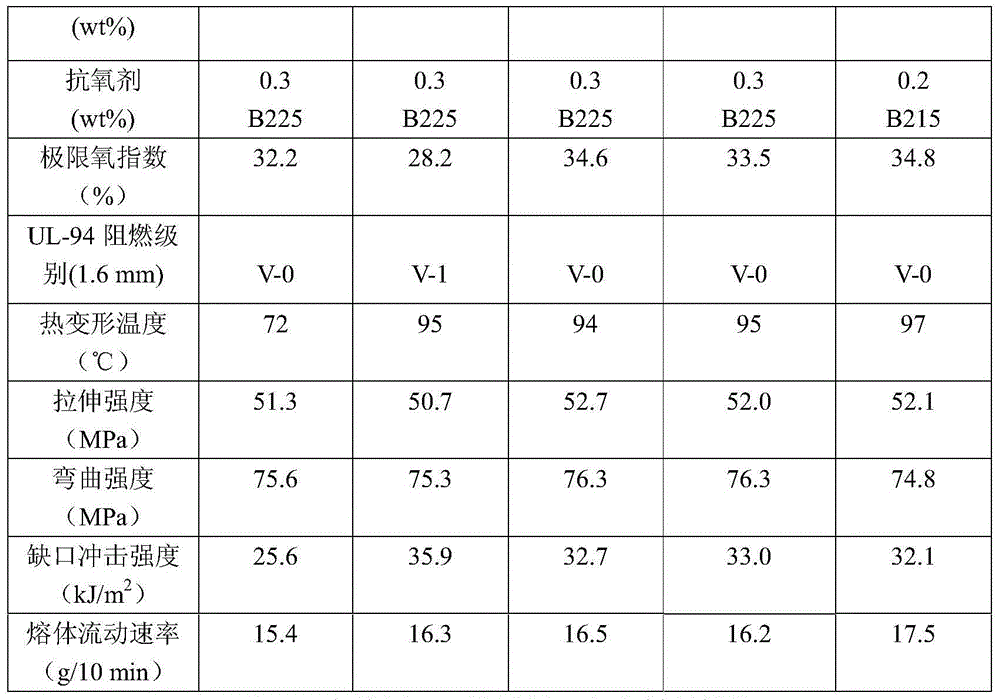

Embodiment 1

[0022] The total amount of control is 3Kg, according to 56.3wt% (mass percentage) PC, 24.1wt% ABS, 8.0wt% RDP, 6.0wt% PPSi, 5.0wt% polydimethylsiloxane-styrene-methyl methacrylate Copolymer (the trade mark is SRK-200A), 0.3wt% anti-dripping agent (the trade mark is PTFE LK-6102), 0.3 wt% antioxidant (the trade mark is B225) joins in the high-speed mixer, after stirring and mixing evenly, the obtained prepared The mixed material is melted, kneaded, extruded, cooled, pelletized and dried through a twin-screw extruder at a temperature of 240-270° C. to obtain a double-ring cage-shaped phosphate ester siloxane flame-retardant PC / ABS alloy material. Change the proportioning of each raw material (such as Table 1 and Table 2), and prepare other 7 examples of the present invention according to the method of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat distortion temperature | aaaaa | aaaaa |

| Notched impact strength | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com