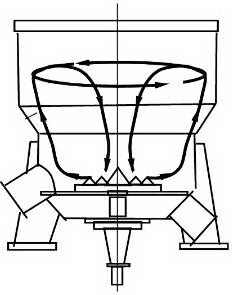

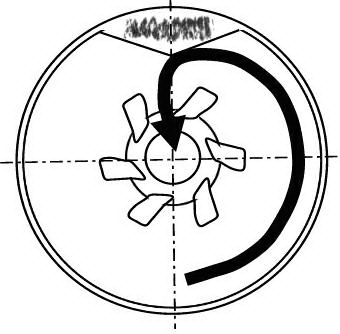

Vertical hydrapulper with drum groove body and spiral backflow plates

A hydraulic pulper, plate vertical technology, applied in the direction of textiles and papermaking, raw material separation, papermaking, etc., can solve the problems of uneven force on the tank body, reduced fiber friction, increased maintenance costs, etc., to achieve enhanced pulping Opportunity and effect, increase centripetal reaction force, effect of saving space and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

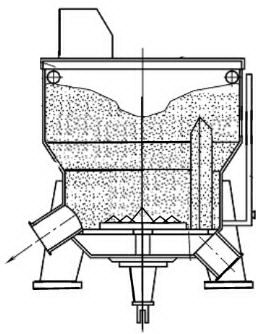

[0056] The vertical hydraulic pulper of the drum groove body spiral backflow plate of the present embodiment is as follows: Figure 11 As shown, the tank body is in the shape of a drum with a large middle and a small diameter at the upper and lower parts, including an upper straight body part 1, an upper ellipsoid body part 2 and a lower inverted cone part 3 connected in sequence. The height of the tank body is 1.0-1.2 times of its maximum end face diameter, and the maximum end face diameter is located at the junction of the upper ellipsoidal part 2 and the lower inverted cone part 3 .

[0057] The upper straight body part 1 is located at the top of the tank body, the tank wall is perpendicular to the tank bottom surface, its height accounts for about 18% of the tank body height, and the working liquid level is located below the vertical wall surface.

[0058] The diameter of the upper ellipsoid part 2 gradually increases from top to bottom, and it is an elliptical arc seen fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pitch | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com