Prestress concrete box girder end sealing formwork construction method

A technology of concrete box girder and construction method, applied in bridges, bridge construction, bridge materials, etc., can solve the problems of large investment in personnel and machinery, low safety performance, long construction period, etc., and achieves low cost investment, reduced pollution, and construction period short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

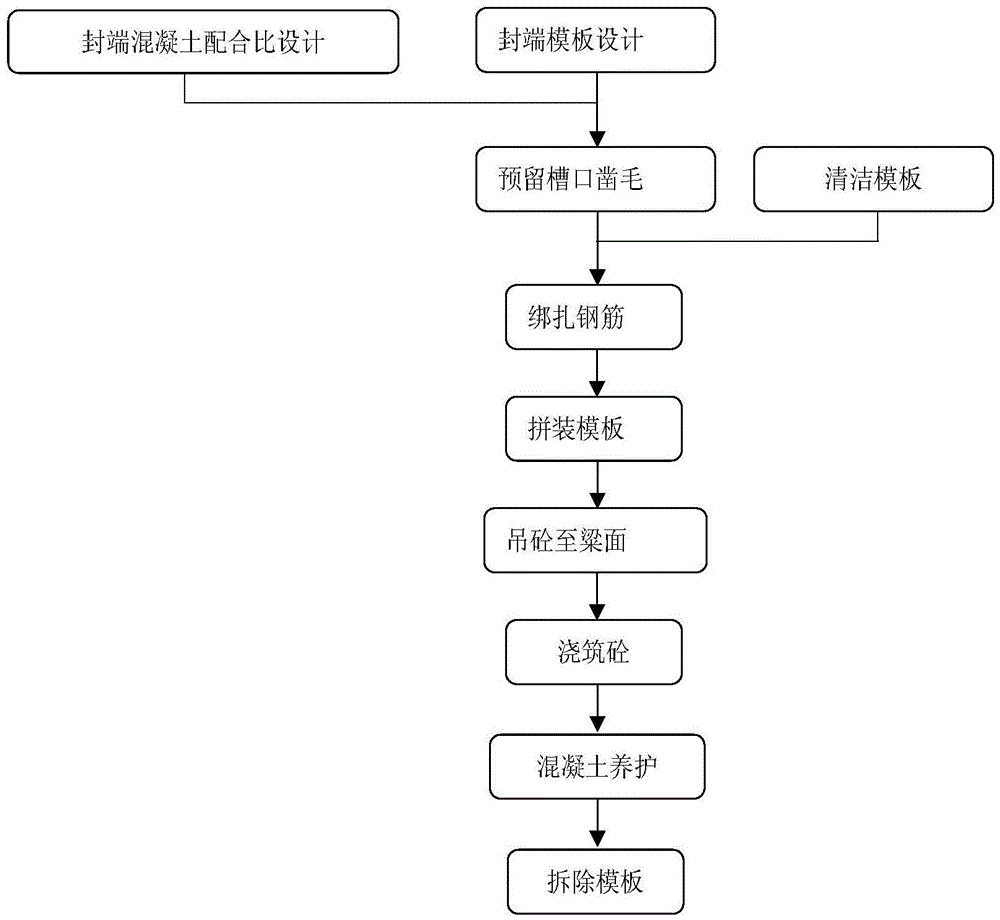

Image

Examples

Embodiment 1

[0023] In this example, the structural form of the beam end and the actual situation on site (the adjacent beam gap width is 10cm, the pier height is 0.5m-18m, and there is no construction space on the top of the pier, etc.), the design uses 3mm steel plate as the panel of the formwork, and the angle steel ∠30× 4. The combined form of small steel molds used as ribs ensures sufficient rigidity of the formwork and at the same time solves the requirements of light weight and convenient operation;

[0024] The combined formwork (the formwork is welded by thin steel plate and angle steel as the back corrugation, and the whole set of formwork is reinforced by bolts, U-shaped clips, and tie rods) is divided into three parts: the inner and outer sides of the web, the bottom plate and the end formwork, all according to The beam profile designs its formwork shape. Among them, the bottom plate and the web formwork are designed to overlap 5cm inside, and the outside is close to the end fo...

Embodiment

[0055] Embodiment Benefits and advantages

[0056] 1 The overall design is the construction method of transporting concrete under the bridge - mechanical lifting - pouring concrete on the bridge deck, which not only solves the technical problem that concrete trucks cannot go on the bridge for construction, but also forms a cyclic operation system with a short construction period.

[0057] 2 The overall design solves the end-sealing construction of the narrow space at the beam end and pier top.

[0058] 3 Light weight, the formwork is welded with thin steel plate and angle steel as the back corrugation; good rigidity, can be recycled repeatedly.

[0059] 4. It is easy to operate. The whole set of formwork is reinforced with bolts, U-shaped clips and tie rods, which is easy to master and has low labor intensity; and the reinforcement is firm and reliable, with strong integrity and safe and reliable construction.

[0060] 5 Compared with the common method (the method of using ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com