Horizontal drainage system for vacuum preloading processing soft soil foundation

A soft soil foundation, horizontal drainage technology, applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of high construction difficulty, high labor cost, increased vacuum loss, etc., to reduce project cost and implementation risk. , Wide distribution of raw materials, small loss of vacuum degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

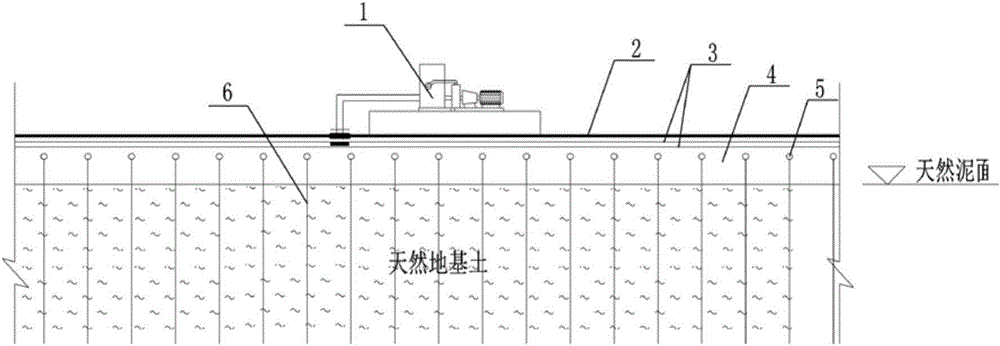

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0015] The present invention is a horizontal drainage system for vacuum preloading treatment of soft ground, comprising a drainage filter pipe 5, a drainage cushion 4 and an anti-cracking layer 3, and the drainage cushion 4 adopts graded crushed stones and pebbles with a diameter of 10 mm to 30 mm Coarse particles are mixed with mineral powder with a diameter of 0.075mm-0.5mm and medium-fine sand as fine particles in a weight ratio of 1:1; the mud content of the drainage cushion 4 is 5%-10%, and the permeability coefficient Greater than 1×10 -4 m 3 / s, the thickness of the drainage cushion layer 4 is 40cm~100cm, and the upper part of the drainage cushion layer is provided with a 400m 2 / s composite geotextile as anti-burst layer 3.

[0016] Drainage cushion 4 is mixed in advance according to the above-mentioned ratio, and after mixing, it is transported to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com