A carbon fiber honeycomb skeleton and a plugging process for making carbon fiber honeycomb

A technology of carbon fiber and carbon fiber board, applied in the direction of slender components, building components, etc., can solve the problems of uneven rigidity of honeycomb surface and low efficiency of gluing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

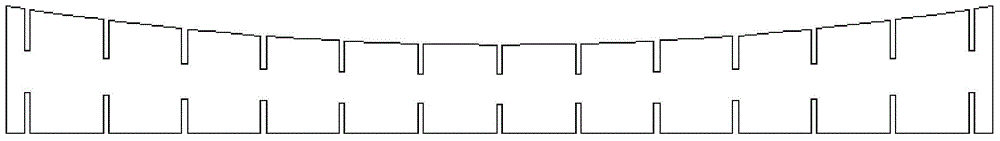

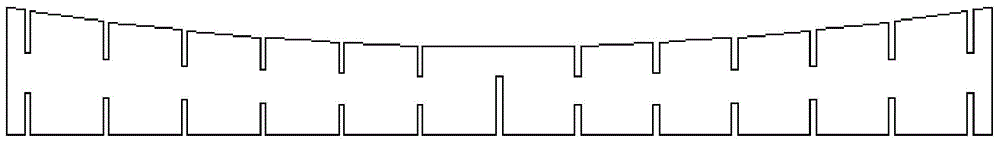

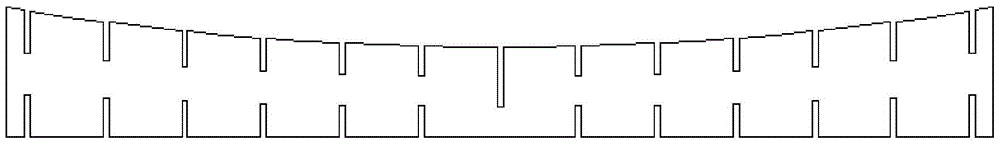

[0103] Example: such as Figure 1-Figure 10 shown.

[0104] First, based on the basic carbon fiber honeycomb panel 1, the central plug-in unit composed of carbon fiber honeycomb panels 2 and 3 is plugged up and down to form three evenly distributed honeycomb panels, and then the honeycomb panels 4, 5, 6, 7, 8, and 9 are plugged up and down in sequence, and then by analogy, the plugging of the entire honeycomb is completed from the inside to the outside.

[0105] Finally, select the appropriate structural adhesive for honeycomb adhesive process implementation. Structural adhesives must be fully suitable for the bonding of composite materials, can be cured at room temperature, have the characteristics of temperature resistance, environmental resistance and durability, small shrinkage after curing, and high tensile strength. The specific gluing method is: hand-held glue gun uses the mixing nozzle to directly inject glue at the joint of the plug-in board, and after it is complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com