Detection device and detection method for detecting the growth rate and diameter of polycrystalline silicon rod

A technology of growth rate and polysilicon rods, which is applied in the direction of measuring devices, devices used to measure the time required to move a certain distance, optical devices, etc., can solve the problems of wasting energy, materials, current matching can not achieve the best effect, and raw material gas is vented and other issues to achieve the effect of improving operational efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

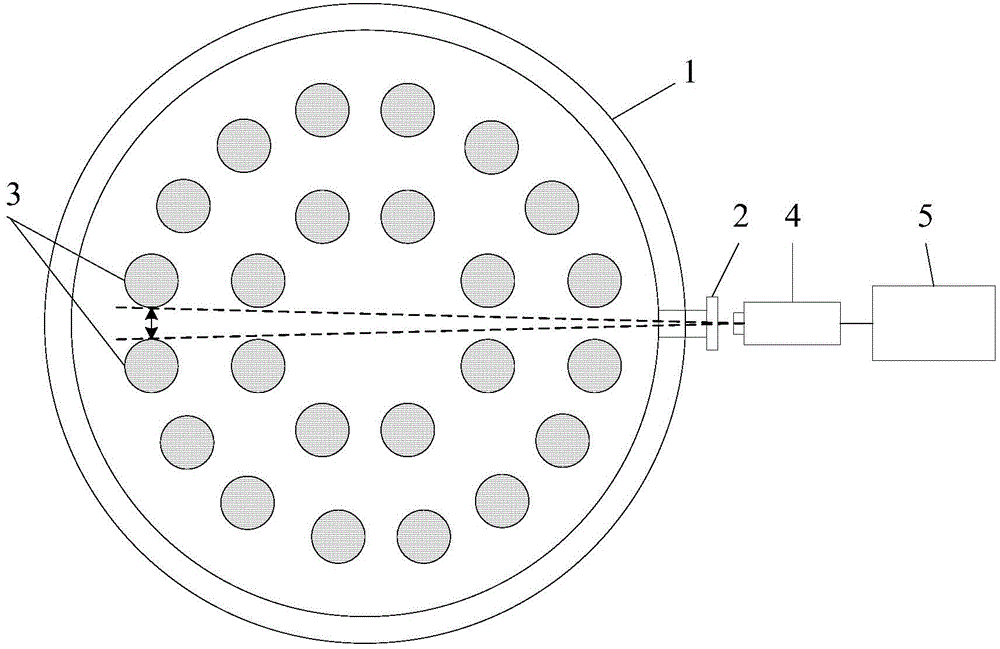

[0034] Embodiment 1: A detection device for the growth rate and diameter of a polycrystalline silicon rod, which includes a high-temperature-resistant fixed-focus digital camera 4 and an industrial computer 5, the high-temperature-resistant fixed-focus digital camera 4 is electrically connected to the industrial computer 5, and the high-temperature resistant fixed-focus digital camera 4. Set in front of the quartz mirror 2 on the furnace wall of the polysilicon reduction furnace 1.

Embodiment 2

[0035] Embodiment 2: A method for detecting a polysilicon rod growth rate and diameter using a detection device in Embodiment 1, which includes the following steps: (1) placing a silicon rod core in a polysilicon reduction furnace; (2) collecting data by a camera; (3) Industrial computer data analysis; among them,

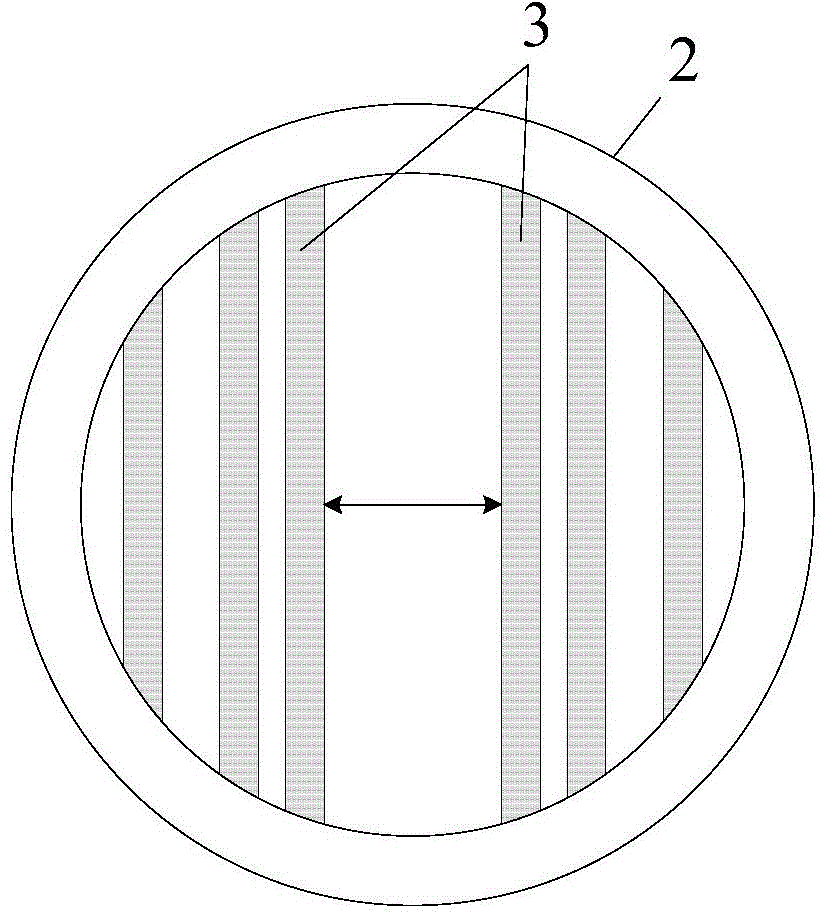

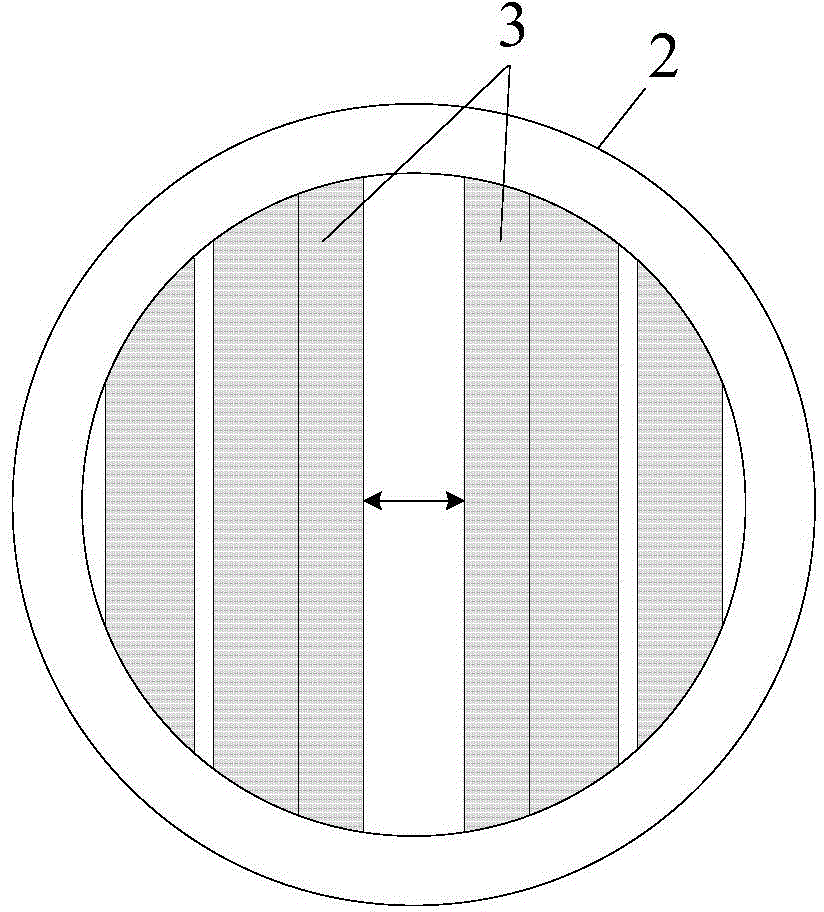

[0036] (1) Silicon rod cores are placed in the polysilicon reduction furnace: with the diameter of the quartz mirror 2 as the axis of symmetry, 24 silicon rod cores are evenly and symmetrically arranged on both sides of the axis of symmetry;

[0037] (2) Camera data collection: select a pair of adjacent silicon rod cores on both sides of the symmetry axis as the detection silicon rod 3, adjust the high-temperature resistant fixed-focus digital camera 4 so that the high-temperature resistant fixed-focus digital camera 4 focuses on the detection silicon rod 3, and start Taking pictures continuously to collect image data, and transmitting the collected image data to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com