CT real-time scanning triaxial stress, seepage and chemical coupling rheology test system

A triaxial stress and rheological test technology, applied in the direction of applying stable tension/pressure to test material strength, scientific instruments, permeability/surface area analysis, etc., can solve the problem that the size of the triaxial pressure chamber is large and the hydraulic station is not suitable for long Time work and other issues to achieve reasonable test data results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

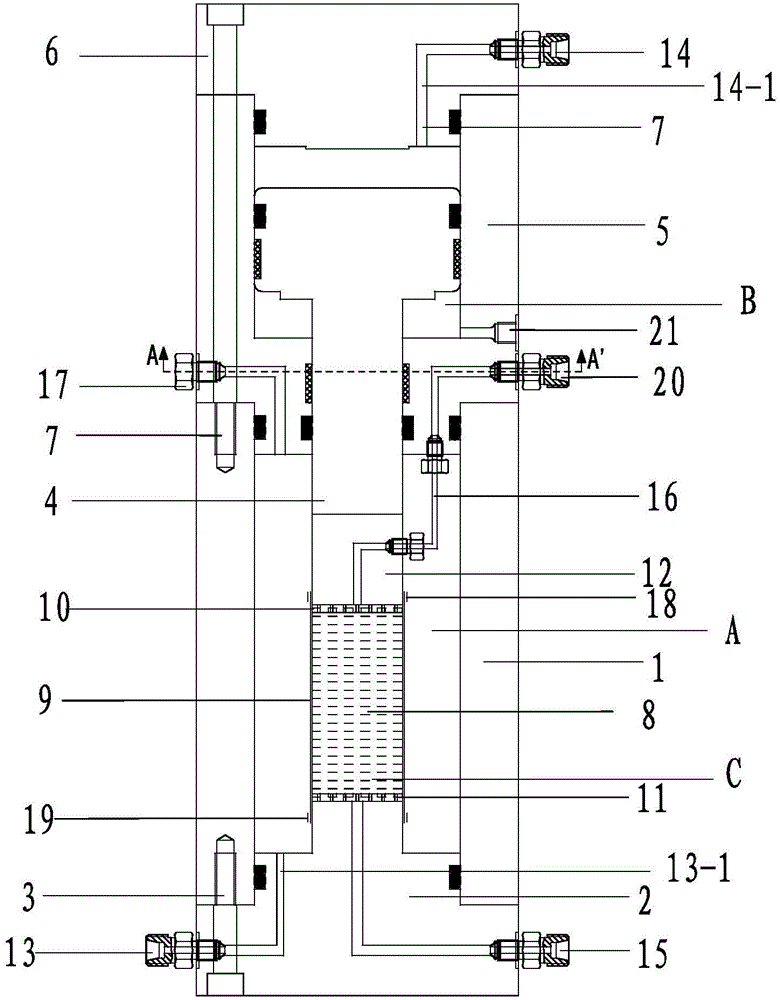

[0030] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand.

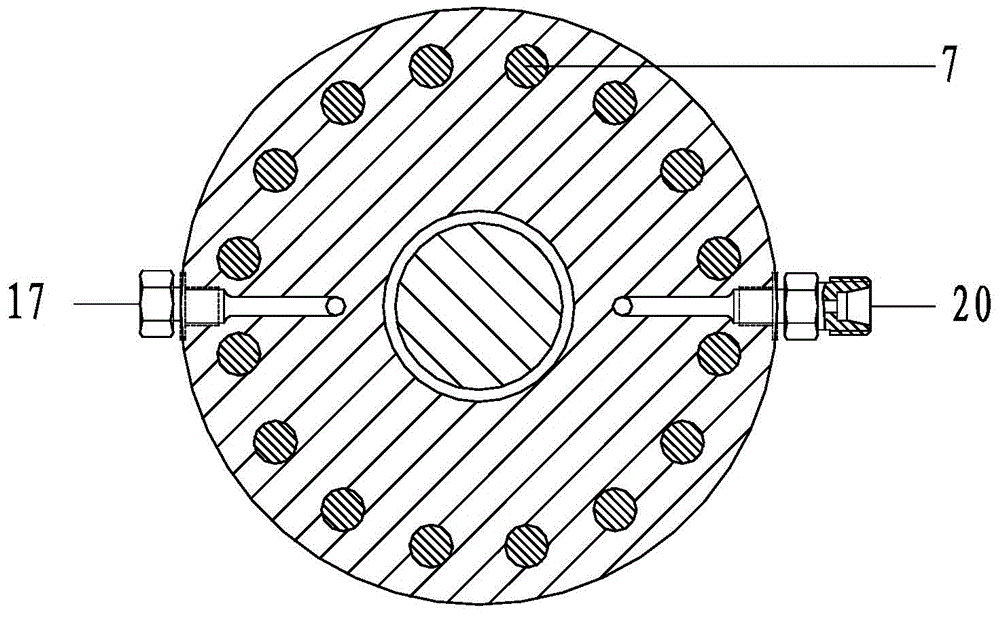

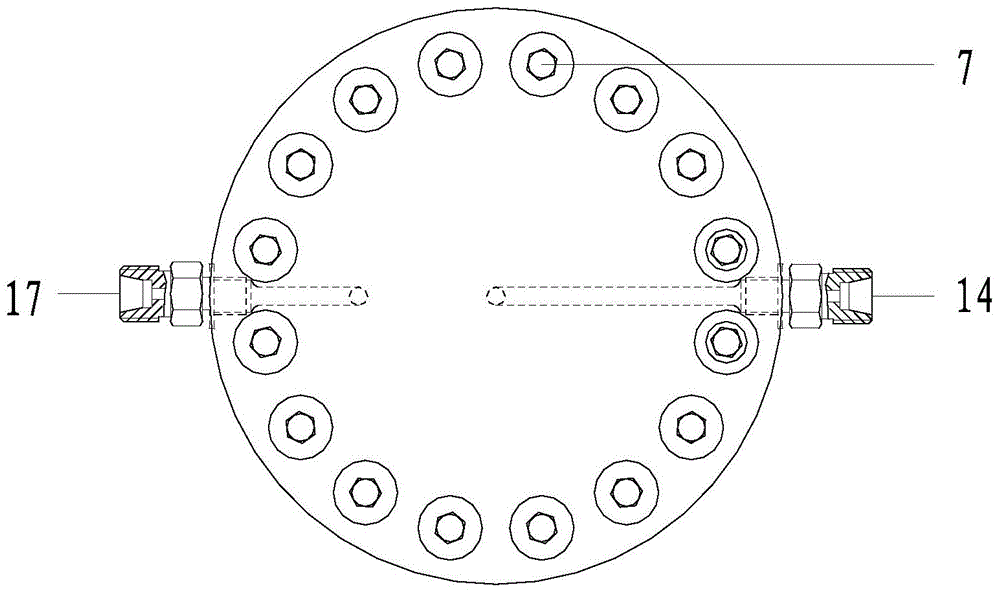

[0031] Referring to the accompanying drawings, it can be seen that the triaxial stress, seepage and chemical coupling rheological test system of CT real-time scanning of the present invention includes confining pressure chamber A, axial pressure chamber B and test chamber C,

[0032] The confining pressure chamber A includes a confining pressure chamber cylinder 1 and a confining pressure cylinder base 2, and the confining pressure cylinder 1 and the confining pressure cylinder base 2 are fixed and sealed by the bottom screw 3;

[0033] The axial pressure chamber B includes an axial piston 4, an axial pressure cylinder 5 and an axial pressure cylinder top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com