Warpage control method of silicon substrate material for gan epitaxy

A control method and technology for silicon substrates, which are used in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of large thermal expansion coefficient, large wafer warpage, and high lattice mismatch rate, and reduce a large number of The incidence of defects and the effect of reducing the warpage variation of silicon wafers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The method for controlling the warpage of the silicon substrate material for GaN epitaxy according to the present invention will be further described in detail below in conjunction with the accompanying drawings.

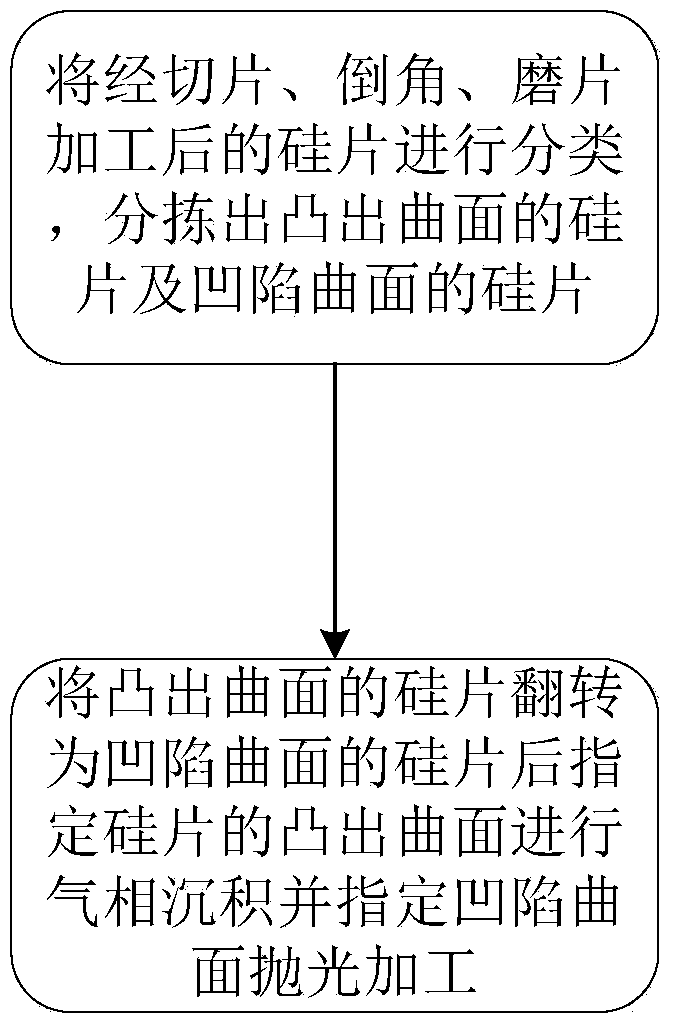

[0011] Such as figure 1 As shown, the method for controlling the warpage of silicon substrate materials for GaN epitaxy in the present invention first classifies the silicon wafers processed by slicing, chamfering and grinding, and sorts out the silicon wafers with convex curved surface (+BOW) And the silicon wafer with concave surface (-BOW), then turn the silicon wafer with convex surface into the silicon wafer with concave surface, and then specify the convex surface of the silicon wafer for vapor deposition and specify the concave surface polishing process.

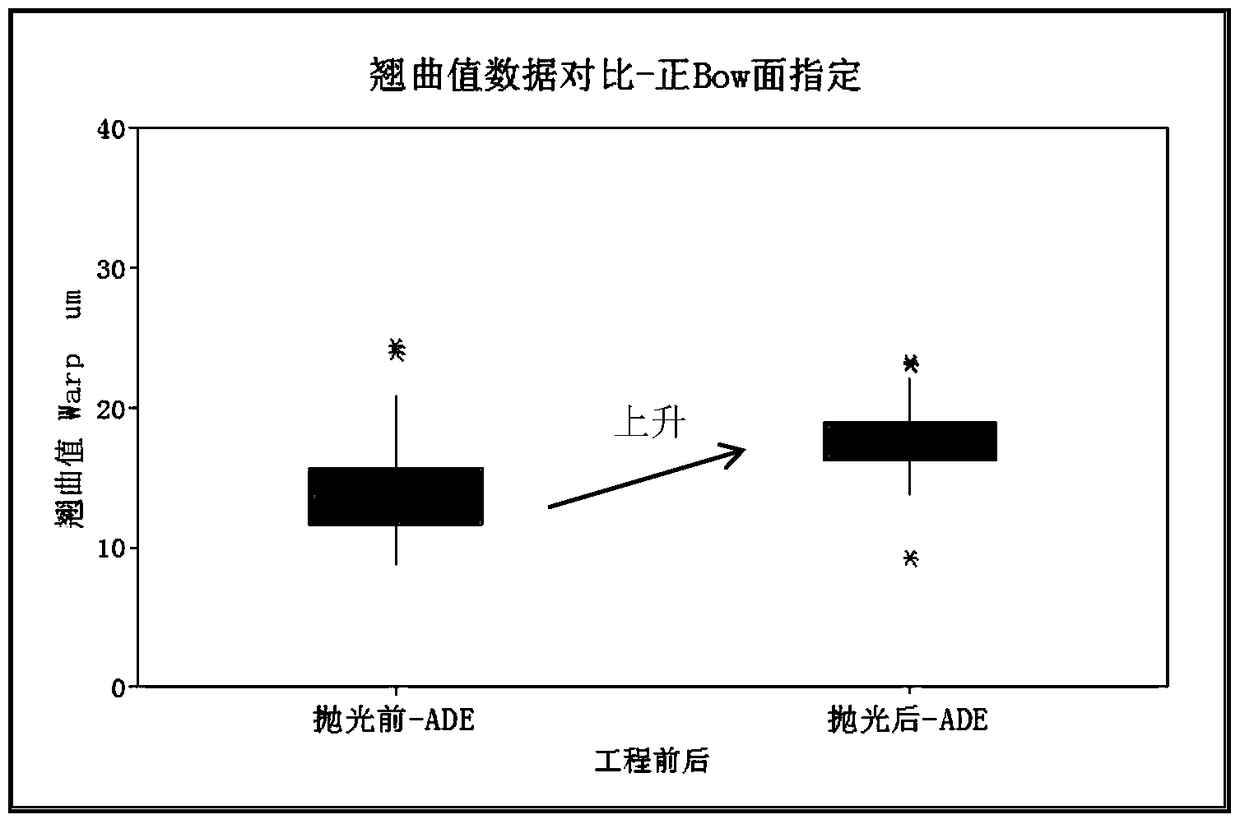

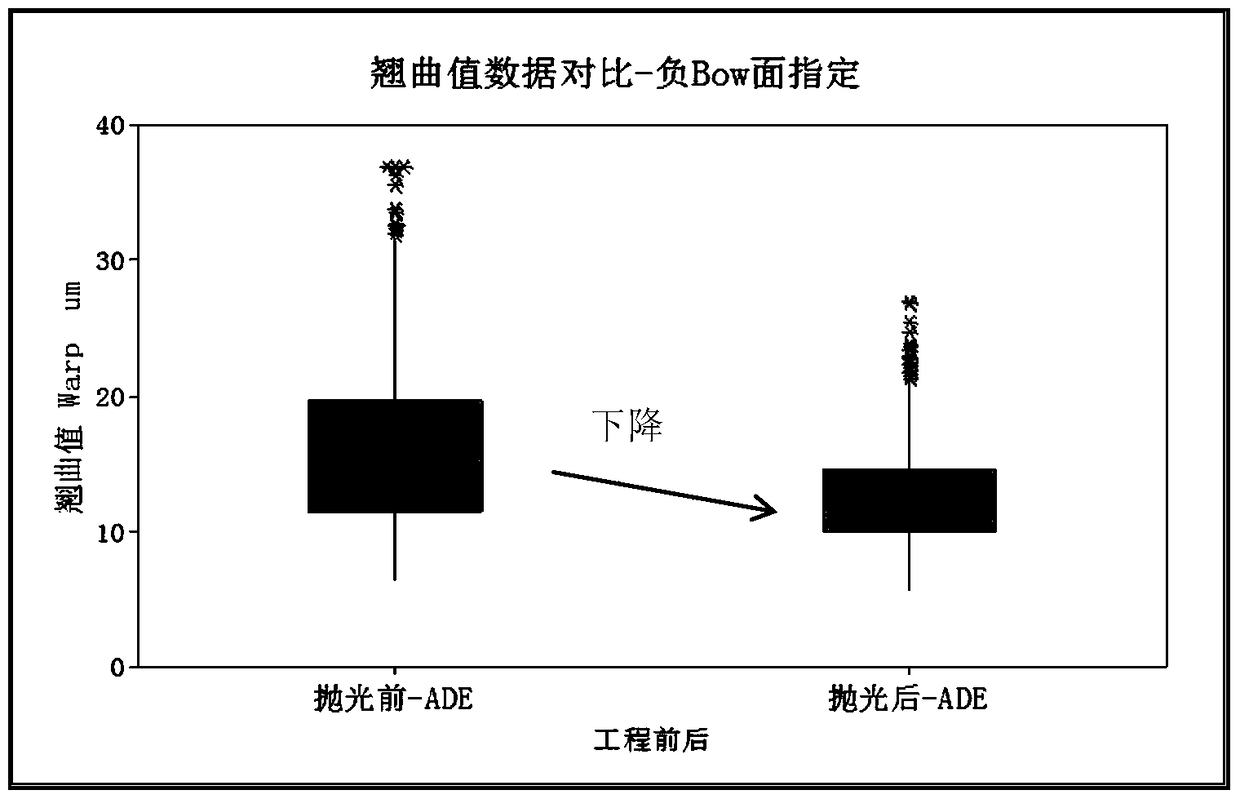

[0012] figure 2 It is: designate the concave curved surface as the vapor deposition surface, and designate the convex curved silicon wafer as the polished surface to change the warpage data before ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com