LED epitaxial wafer and preparation method thereof

An LED epitaxial wafer and epitaxial growth technology, applied in chemical instruments and methods, crystal growth, electrical components, etc., can solve the problems of insufficient surface flatness of epitaxial wafers and high defect density of epitaxial wafers, and increase antistatic ability, crystal lattice, etc. Good quality, avoid too fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

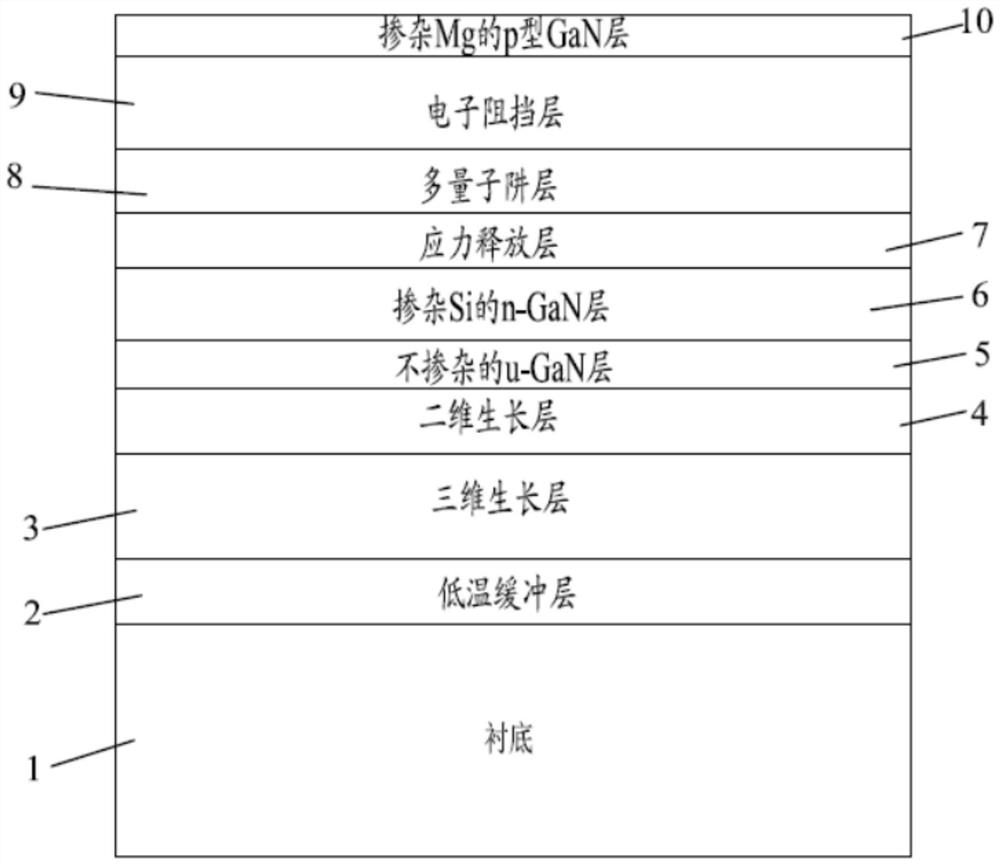

[0036] see figure 1 , shows the LED epitaxial wafer in the first embodiment of the present invention, including a substrate 1, and a low-temperature buffer layer 2, a three-dimensional growth layer 3, a two-dimensional growth layer 4, a GaN layer, a stress Release layer 7 , multiple quantum well layer 8 , electron blocking layer 9 and Mg-doped p-type GaN layer 10 , wherein the GaN layer includes an undoped u-GaN layer 5 sequentially grown on the two-dimensional growth layer 4 And the Si-doped n-GaN layer 6 , a stress relief layer 7 is grown on the Si-doped n-GaN layer 6 .

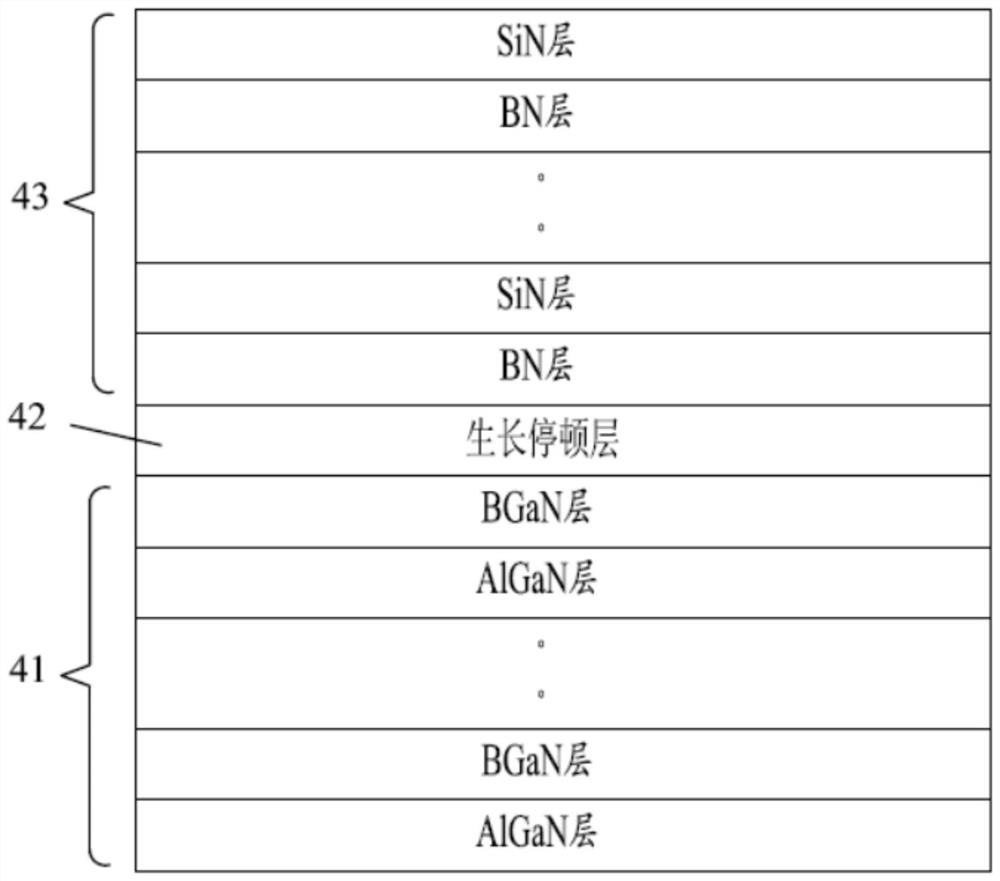

[0037] In this example, see figure 2 , the two-dimensional growth layer 4 includes a first sub-layer 41, a second sub-layer 42 and a third sub-layer 43 grown in sequence; wherein, the first sub-layer 41 is composed of AlGaN layers and BGaN layers that are repeatedly overlapped (alternately stacked) Periodic composite layer, and in the growth cycle of the first sublayer 41, the growth temperature increase...

Embodiment 2

[0042] The second embodiment of the present invention provides a method for preparing an LED epitaxial wafer, which is used for preparing the LED epitaxial wafer in the above-mentioned first embodiment. The method specifically includes steps S21 to S30, wherein:

[0043] Step S21, providing a substrate required for epitaxial growth, preferably a sapphire substrate.

[0044] Specifically, the temperature can be controlled to be 1000 ° C ~ 1200 ° C, at H 2 The substrate is annealed at high temperature for about 5 min under the atmosphere.

[0045] In step S22, a low temperature buffer layer is grown on the substrate, the material of the low temperature buffer layer may be AlGaN, the temperature of the reaction chamber is 500°C to 700°C, and the pressure is 200 to 400 Torr.

[0046] Step S23 , growing a three-dimensional growth layer on the low temperature buffer layer, the temperature of the three-dimensional growth layer reaction chamber is 1000° C.˜1050° C., and the pressure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com