Intelligent control mode for barrel fixing

A control mode, the technology of drum fixing, applied in the direction of tea processing before extraction, can solve the problems of different fixing process conditions and low production efficiency, and achieve the effect of ensuring the quality of fixing and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to facilitate the understanding and implementation of the present invention, a preferred embodiment of the present invention is selected for further description.

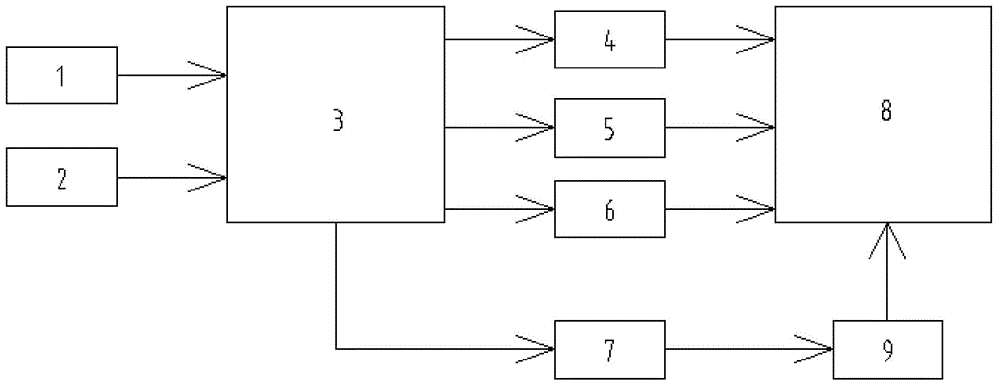

[0020] like figure 1 As shown, a kind of drum finishing intelligent control mode described in this embodiment, the steps are:

[0021] Step 1. Pre-set the tea tenderness level to multiple levels, determine the tea tenderness level 1 according to the condition of the tea raw materials, and input the tea tenderness level 1 into the control system 3;

[0022] Step 2, measuring the moisture content 2 of the tea leaves, and inputting the moisture content 2 of the tea leaves into the control system 3;

[0023] Step 3, the control system 3 automatically sets the drum inclination 4, heating temperature 5, and drum speed 6 of the drum greening machine 8 according to the tea tenderness level 1 and the tea moisture content 2, and then starts the drum greening machine 8, and the drum greening machine 8 meets th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com