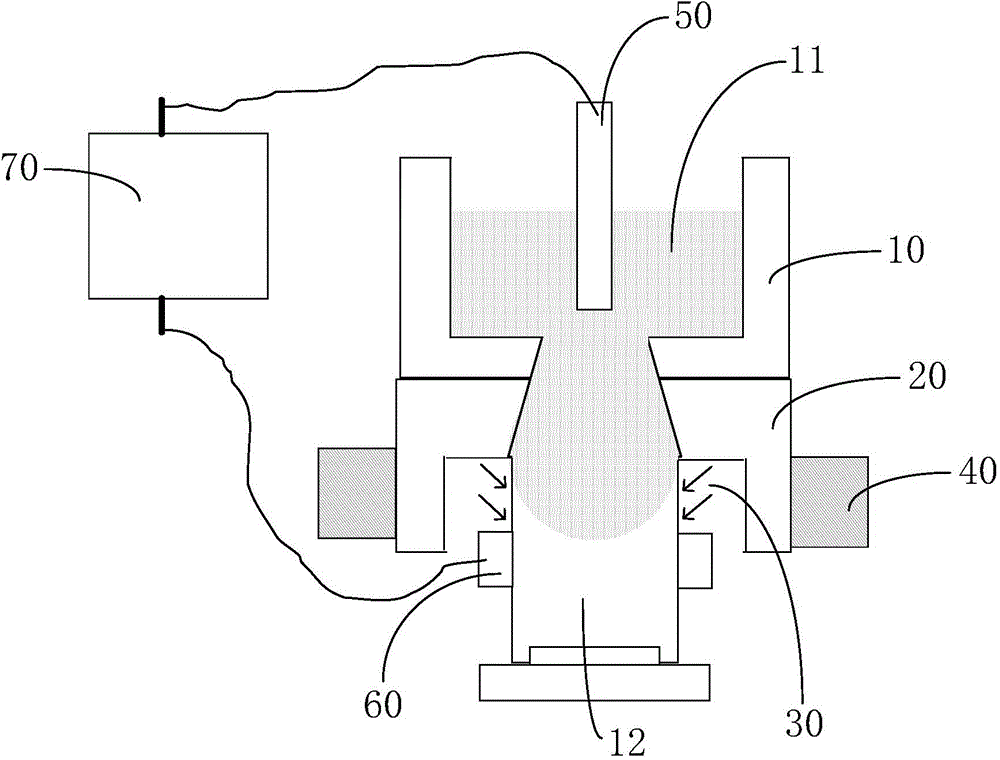

Aluminum alloy semi-continuous cast electromagnetic stirring device and method

An electromagnetic stirring and semi-continuous technology, applied in the field of foundry metallurgy, can solve the problems of long flow formation time, inability to adapt to the solidification speed of semi-continuous casting, uncontrollable flow mode, etc., and achieve the effect of homogenization and refinement of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

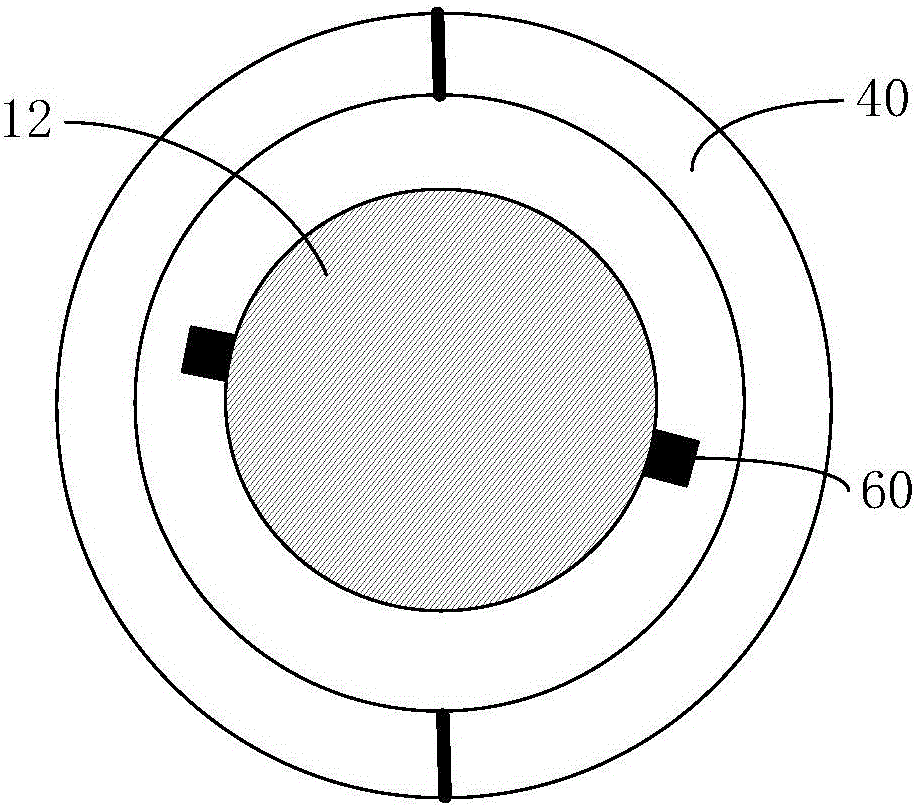

[0028] For round ingots with small diameter (eg φ=180mm), please refer to figure 2 , using the design of half-type permanent magnets, the sliding electrodes 60 are two or four, arranged in pairs, and the current adopts 10A, pulsed continuous current. For A356 alloy, the grain size can be controlled below 50 microns.

Embodiment 2

[0030] For a round ingot with a large diameter (eg, φ=500mm), a half-type permanent magnet design is adopted, and the sliding electrodes 60 are four or six, arranged in pairs, and the current adopts 30A, a pulsed continuous current. For 6016 alloy, the grain size can be controlled below 100 microns.

Embodiment 3

[0032] For large slab ingots (for example, the size is 1300mm×620mm), use the opposed multi-pole magnet design, design 4-6 pairs of sliding electrodes 60 on the long side, and design 2 pairs of electrodes on the short side, the current adopts 50A, pulse type and The electric current whose polarity is periodically reversed is used to balance the temperature of the large-section melt 11 and the distribution of alloying elements. The grain size of 6061 alloy can be controlled below 300 microns.

[0033] In summary, the present invention provides an aluminum alloy semi-continuous casting electromagnetic stirring device and method, the device includes a launder 10 for carrying a melt 11, a crystallizer 20 is provided under the launder 10, and the The lower outlet of the crystallizer 20 is provided with a cooling water injection zone 30, the outside of the crystallizer 20 is provided with permanent magnets 40 in pairs, the melt 11 is inserted with a graphite electrode 50, and the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com