Curve cutting machine for amorphous alloy strips

An amorphous alloy and cutting machine technology, applied in the field of mechanical processing, can solve the problems of easy lateral tearing, high brittleness, and high hardness of amorphous alloy strips, and achieve the effects of avoiding tearing, small tensile force, and preventing tearing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to have a clearer understanding of the technical features, objects and effects of the present invention, the specific embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

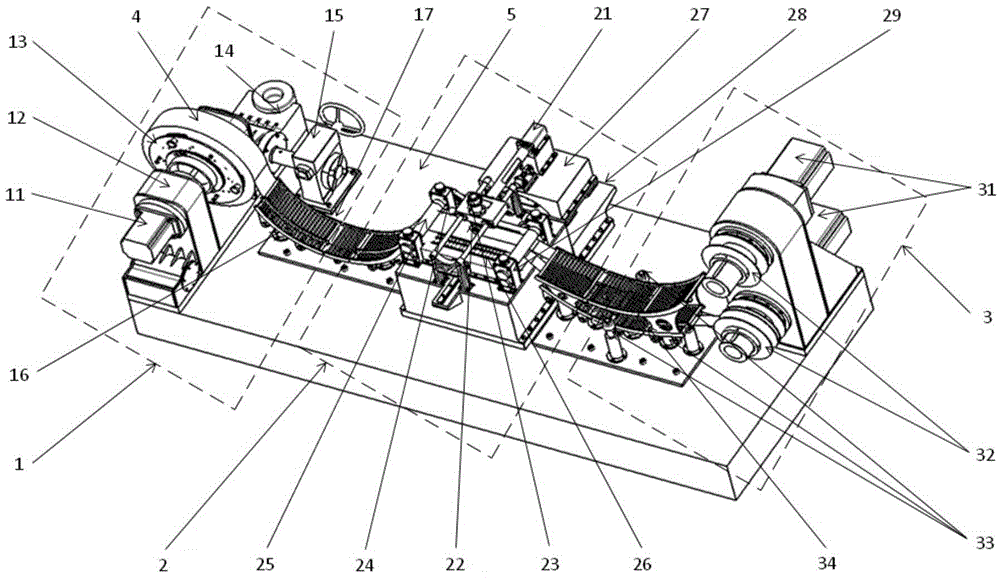

[0018] like figure 1 shown, as figure 1 As shown, the amorphous alloy strip curve cutting machine of the present invention includes a strip zone 1 , a shear zone 2 , and a take-up zone 3 .

[0019] The tape-playing area 1 includes a tape-playing servo motor 11 , an auxiliary support base 12 , a lifting device 13 , a reversible fixing base 14 , a turning system 15 , a tape-playing zone pressure sensor 16 , and a sensor frame 7 . The amorphous tape needs to be installed in the tape-out zone 1 of the present invention. The rolled amorphous alloy strip is placed on the lifting device 13 , and the lifting device 13 is turned over by operating the turning system 15 and fixed on the turnable fixing base 14 . At this time, the strip wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com