Fixed blade plate full-automatic processing equipment of vehicle hinge

A technology for processing equipment and fixing blades, which is applied to metal processing equipment, metal processing, metal processing machinery parts, etc., and can solve problems such as increased production costs, low work efficiency, and large manpower consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

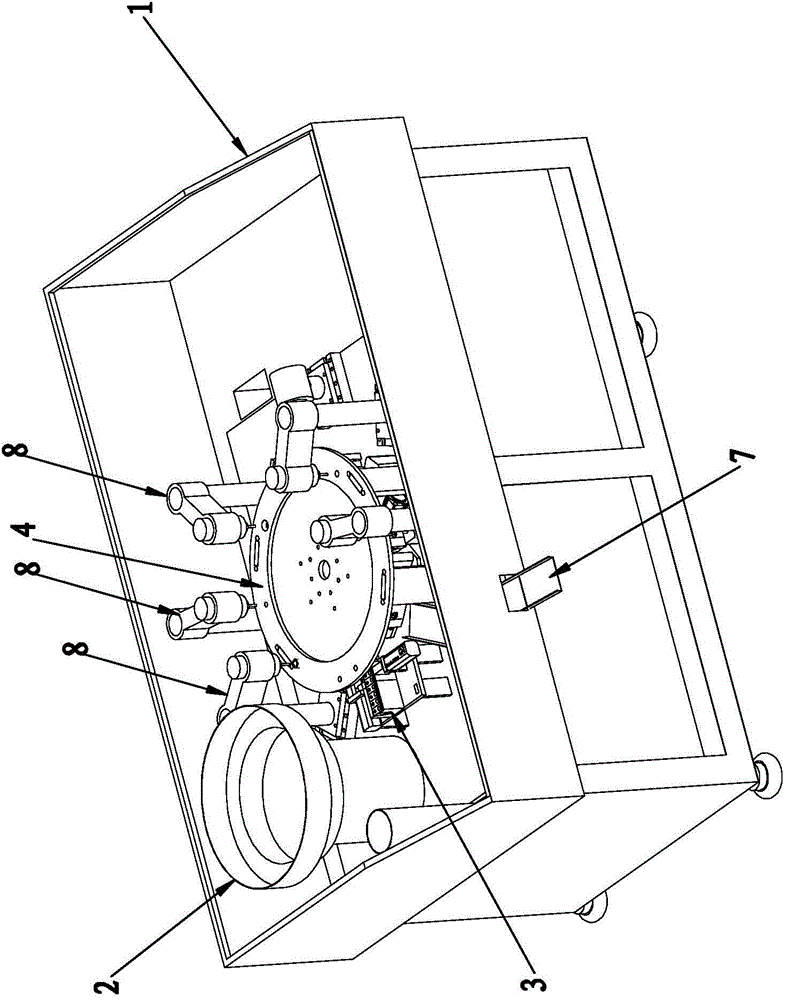

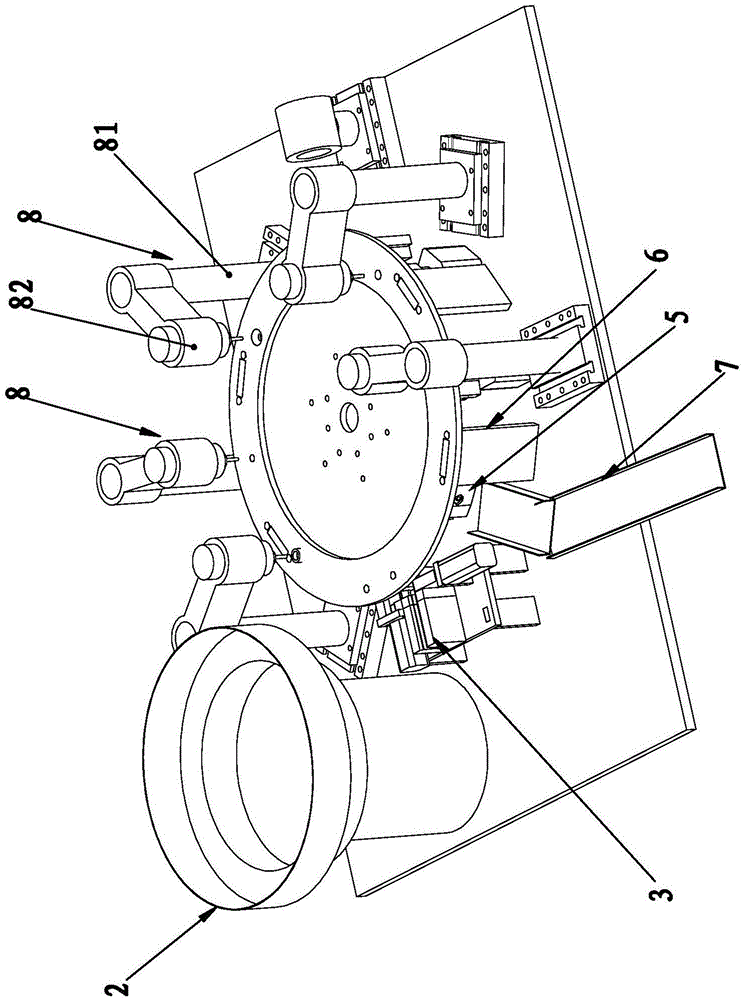

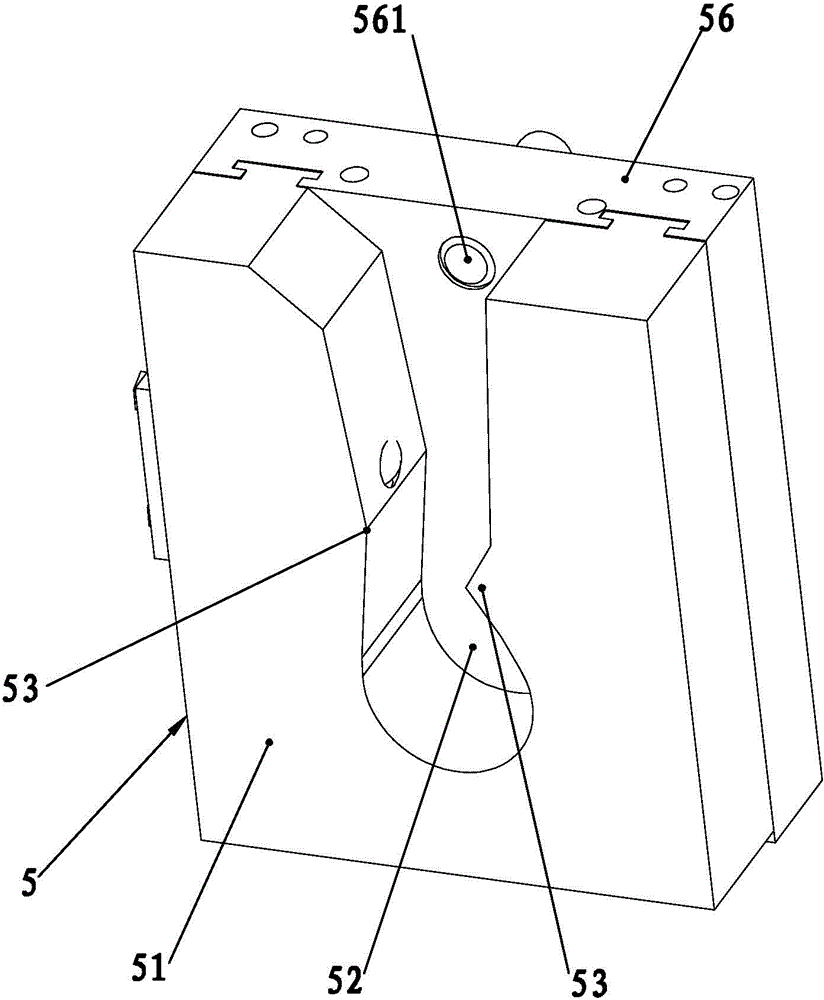

[0022] Such as figure 1 — Image 6 The shown automatic processing equipment for the fixed blade of a vehicle hinge includes a body 1, a tray 2 erected on the body 1, a rotatable workbench 4 connected to the tray 2 through a conveying mechanism 3, and a The fixed blade clamping mechanism 5 on the workbench 4 and the tripping mechanism 6 that can be adapted to the fixed blade clamping mechanism 5 and erected on the body 1, the material output mechanism 7 located at the tripping mechanism 6 and the winding There are at least three drilling mechanisms 8 arranged around the workbench 4 . In the above scheme, when the fixed blade to be processed enters the conveying mechanism 3 from the material tray 2, the conveying mechanism 3 conveys it to the fixed blade clamping mechanism 5 of the workbench 4, and then the workbench 4 rotates, and the The fixed blade clamping mechanism 5 holding the fixed blade is transported to the drilling mechanism 8 for drilling. After the drilling is com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com