Crankshaft follow-up abrasive belt grinding device

A technology of abrasive belt grinding and follow-up, which is applied in the direction of abrasive belt grinders, grinding/polishing equipment, grinding machines, etc., can solve the problems of complex roundness compensation model and complex motion control in finishing machining, so as to improve processing efficiency and Machining quality, ease of crankshaft shape error compensation, overall mass reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing, the patent of the present invention is further described.

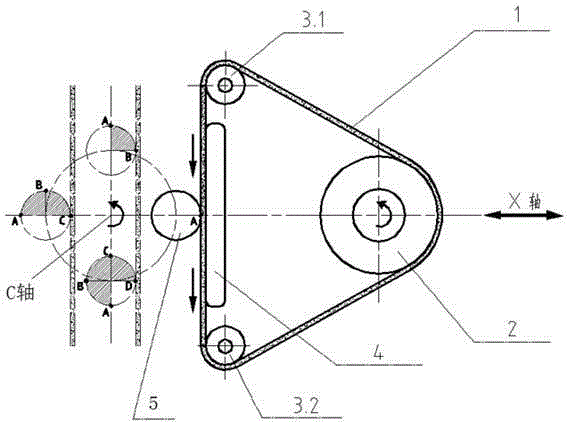

[0011] Such as figure 1 As shown, the crankshaft follow-up abrasive belt grinding device of the present invention includes an abrasive belt 1, a drive wheel 2, upper and lower support wheels 3.1, 3.2, shape and position support blocks 4, and the like.

[0012] The abrasive belt 1 surrounds the driving wheel 2 and the upper and lower supporting wheels 3.1 and 3.2, and the abrasive belt 1 is driven by the driving wheel 2 and supported and tensioned by the upper and lower supporting wheels 3.1 and 3.2 to realize abrasive belt grinding. The movement direction of the cutting area is perpendicular to the reciprocating movement direction (X axis) of the whole device, and the tangent direction of the grinding point remains unchanged. The upper and lower supporting wheels 3.1 and 3.2 are adjustable in position, realizing the adjustment of the direction of the abrasive bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com