Micro-pore drilling device for flexible printed circuit board and processing method thereof

A technology of flexible printing and processing methods, applied in metal processing, etc., can solve the problems of difficult acceptance by manufacturers, high production costs, open circuits in holes, etc., and achieve the effect of improving micropore quality, low cost, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

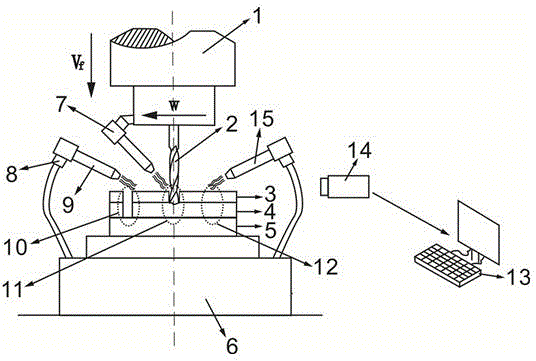

[0016] The structure diagram of the present invention is as figure 1 As shown, the microhole drilling device of the flexible printed circuit board of the present invention includes a cover plate 3, a backing plate 5, and a cold air injection device, wherein the microdrill 2 is installed on the main shaft 1, and the backing plate 5 is fixed on the machine tool table 6, and located below the micro-drill 2, the flexible printed circuit board 4 is placed on the backing plate 5, the cover plate 3 is placed on the top surface of the flexible printed circuit board 4, and the cold air injection device performs The cold air is sprayed to maintain the freezing temperature of the flexible printed circuit board 4. The spray is connected to the air source through the flow valve 8 to keep the gas output stable. The output end is connected to the signal input end of the control device 13, and the signal output end of the control device 13 is connected to the flow valve 8, and the air output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com