Fluid-assisted injection molding system

A technology of injection molding and injection molding machines, which is applied in the field of polymer material molding devices, and can solve problems such as water injection, affecting production continuity, and relaxation of melt pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] specific implementation plan

[0015] The technical characteristics of the present invention and related technologies thereof are further elaborated below in conjunction with the accompanying drawings through specific implementation schemes:

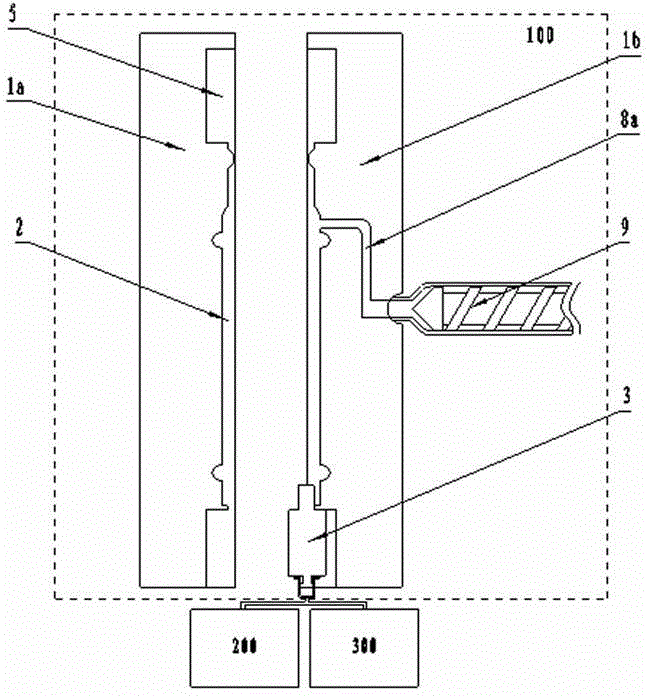

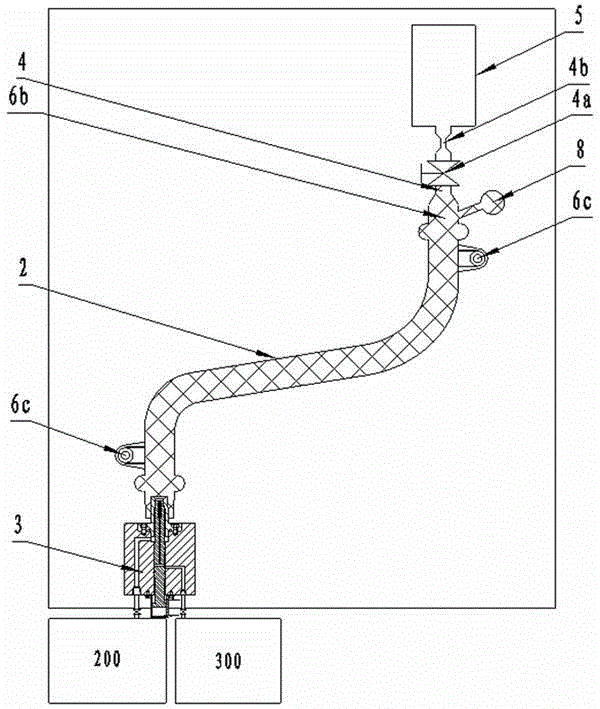

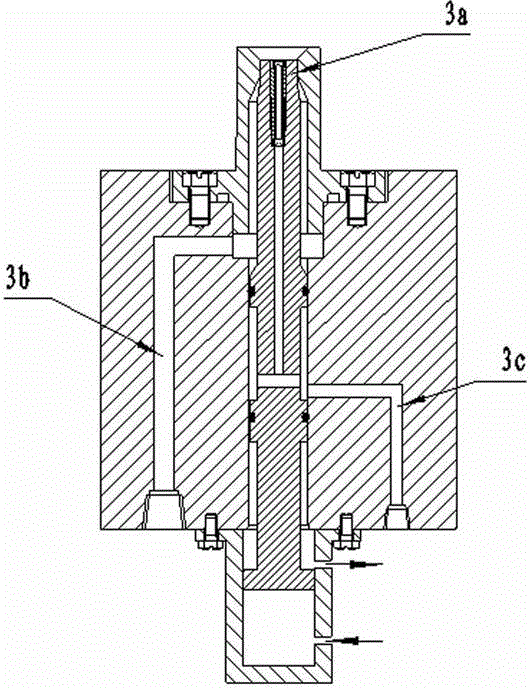

[0016] Such as Figure 1-8 Schematic, the numbers in the figure represent respectively: 100 - injection molding machine, 200 - water injection control device, 300 - high pressure gas injection control device, 400 - injection molding mold, 1a - moving mold, 1b - fixed mold, 2 - mold type cavity, 3 - water needle device, 3a - fluid output port, 3b - water channel, 3c - gas channel, 4 - connecting channel, 4a - switch valve, 4b - flow limiting element, 5 - overflow cavity, 6 - hollow product , 6b - process remaining material, 6c - external fixed connection structure, 7 - water, 8 - gate, 8a - runner system, 9 - injection unit of injection molding machine

[0017] Such as Figure 8 The hollow product 6 shown in this embodiment is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com