Forming process of hollow carbon fiber product

A molding process, carbon fiber technology, applied in the field of molding technology of hollow carbon fiber products, can solve problems such as dents and material shortages, and achieve the effect of solving material shortages or dents and good molding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

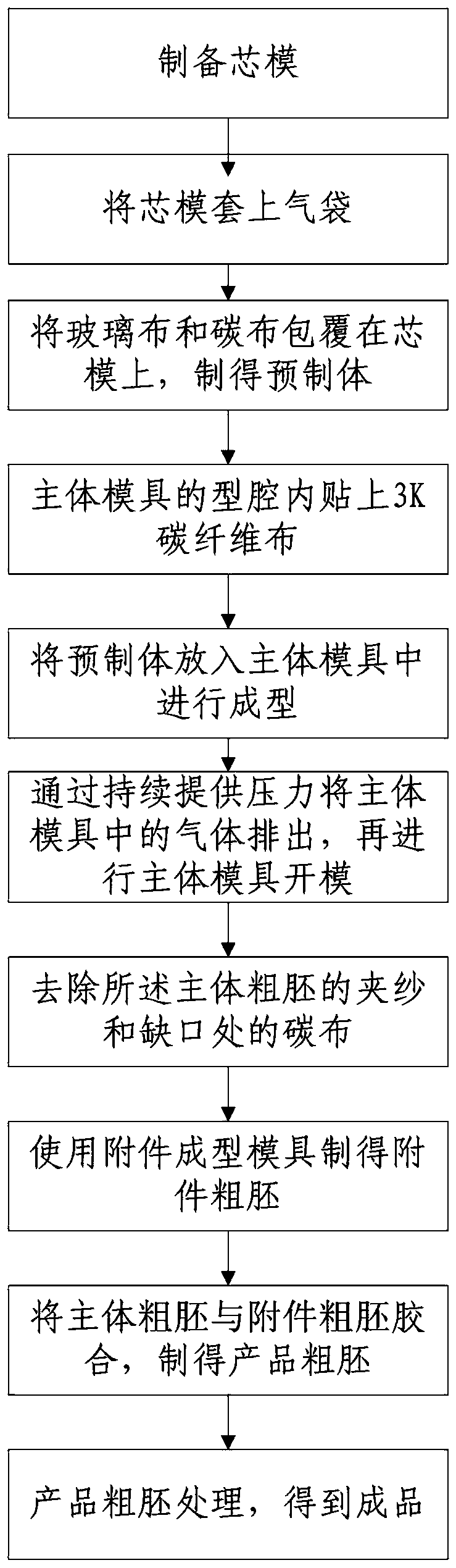

[0083] The molding process of the hollow carbon fiber product of the embodiment of the present invention, the method comprises the following steps:

[0084] S1. Pour the polystyrene foam raw material into the mandrel mold, place the mandrel mold with the polystyrene foam raw material in a vacuum hot-press furnace for molding, and obtain the mandrel;

[0085] S2, putting the mandrel on an air bag;

[0086] S3. Cover the mandrel with glass cloth and carbon cloth according to the shape of the mandrel, reserve an air inlet on the air bag, connect the air bag air inlet to the air pipe on the molding equipment, and obtain a prefabricated product ;

[0087] S4, paste 3K carbon fiber cloth in the cavity of the main mould;

[0088] S5. Put the prefabricated body into the main mold, put the main mold into the forming furnace, connect the air intake pipe, and perform molding control; apply a release agent on the surface of the upper mold and the lower mold of the main mold to facilitat...

Embodiment 2

[0124] Embodiment 2: The molding process of the hollow carbon fiber product of the embodiment of the present invention, the method includes the following steps:

[0125] S1. Pour the polystyrene foam raw material into the mandrel mold, place the mandrel mold with the polystyrene foam raw material in a vacuum hot-press furnace for molding, and obtain the mandrel;

[0126] S2, putting the mandrel on an air bag;

[0127] S3. Cover the mandrel with glass cloth and carbon cloth according to the shape of the mandrel, reserve an air inlet on the air bag, connect the air bag air inlet to the air pipe on the molding equipment, and obtain a prefabricated product ;

[0128] S4, paste 3K carbon fiber cloth in the cavity of the main mould;

[0129] S5. Put the prefabricated body into the main mold, put the main mold into the forming furnace, connect the air intake pipe, and perform molding control; apply a release agent on the surface of the upper mold and the lower mold of the main mold...

Embodiment 3

[0165] Embodiment 3: The molding process of the hollow carbon fiber product of the embodiment of the present invention, the method includes the following steps:

[0166] S1. Pour the polystyrene foam raw material into the mandrel mold, place the mandrel mold with the polystyrene foam raw material in a vacuum hot-press furnace for molding, and obtain the mandrel;

[0167] S2, putting the mandrel on an air bag;

[0168] S3. Cover the mandrel with glass cloth and carbon cloth according to the shape of the mandrel, reserve an air inlet on the air bag, connect the air bag air inlet to the air pipe on the molding equipment, and obtain a prefabricated product ;

[0169] S4, paste 3K carbon fiber cloth in the cavity of the main mould;

[0170] S5. Put the prefabricated body into the main mold, put the main mold into the forming furnace, connect the air intake pipe, and perform molding control; apply a release agent on the surface of the upper mold and the lower mold of the main mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com