An Axial Force-Forcing Mechanism for Welding Plastic Pipe Fittings with Equal Diameters

A technology of plastic pipe fittings and force mechanism, which is applied in the field of plastic pipe processing, can solve the problems of poor seam welding, reduced product or grid, affecting the quality of welding seams, etc., and achieves uniform welding force, compact structure, and guaranteed welding quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

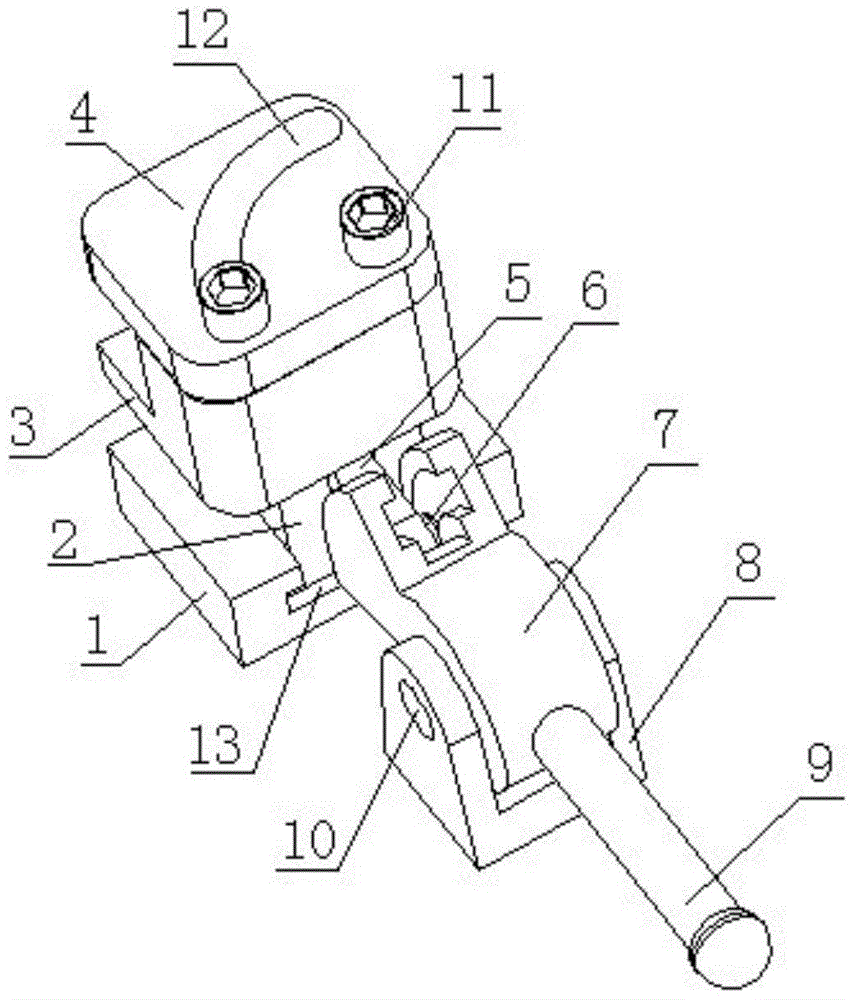

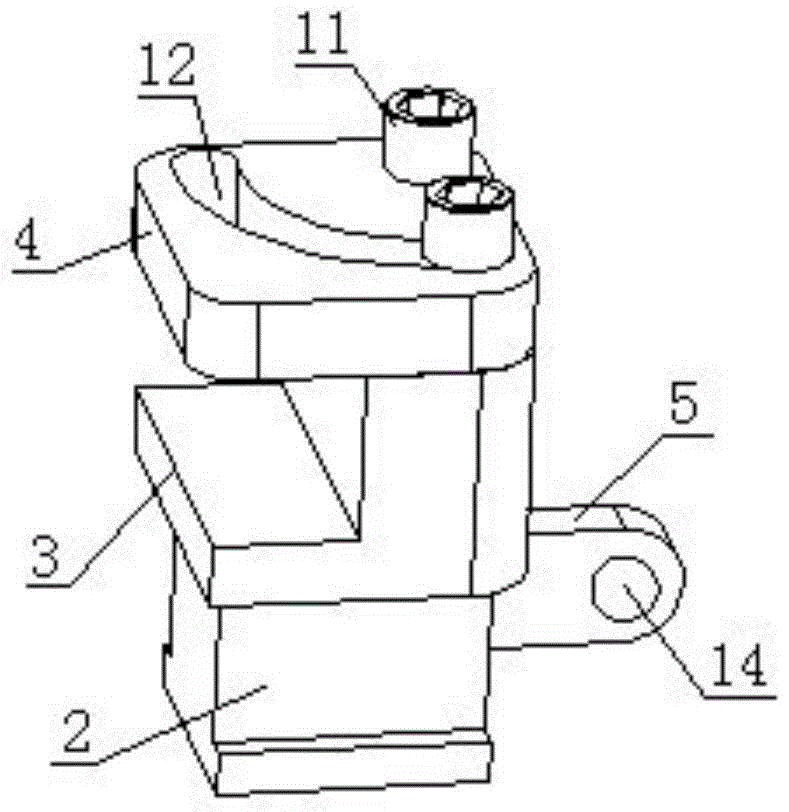

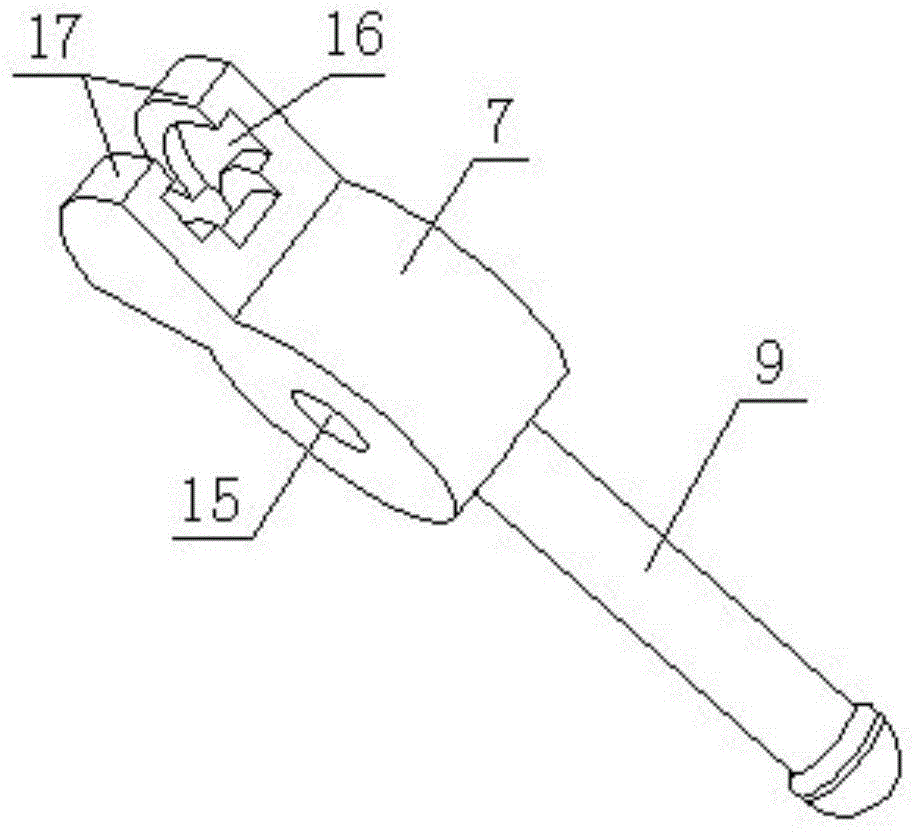

[0021] Such as Figure 1 to Figure 3 As shown, an axial force applying mechanism for welding equal-diameter plastic pipe fittings according to the present invention includes a base 1, a guide block 2, an eccentric lever 7 and a hinge seat 8, and the guide block 2 is installed on the base 1 , a pin seat 5 is provided on the guide block 2, one end of the eccentric lever 7 is connected with the pin seat 5 through the pin shaft A6, and the other end is connected with the hinge seat 8 through the pin shaft B10, and the guide block 2 is also fixed with a force fixture. With this technical solution, when in use, the guide block 2 is pushed forward or backward by rotating the eccentric wheel lever 7, so that the guide block 2 drives the force clamp connected to it to move back and forth, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com