A hydraulic support truck

A technology of hydraulic supports and transport vehicles, which is applied in the direction of motor vehicles, vehicle parts, transportation and packaging, etc., which can solve the problems of poor adaptability of support transport vehicles, difficulties in long-distance transportation, narrow installation roadways, etc., and achieve convenient bearing clearance and improve Safety and reliability, the effect of reducing the number of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

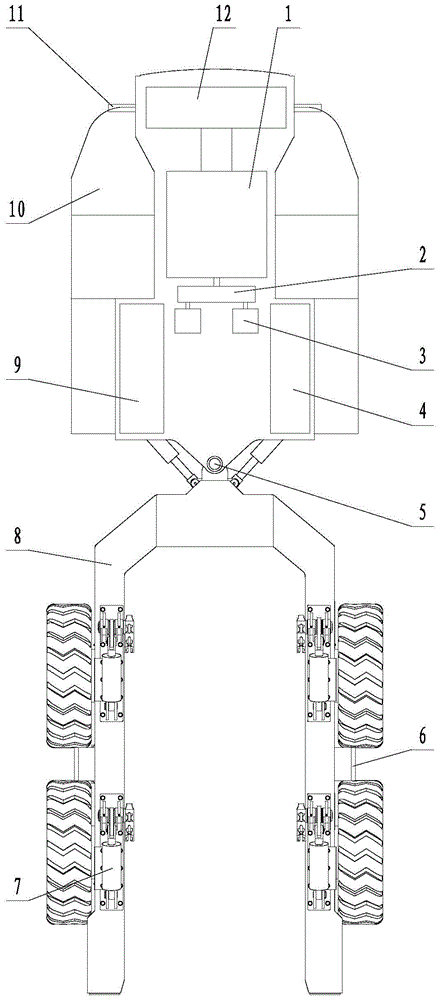

[0041] Such as figure 1 As shown, the hydraulic support truck of the present invention is divided into a front car 10 and a rear car 8, and the rear car 8 is articulated with the front car 8 through the hinge device 5, which can realize a 45° deflection.

[0042] The front car 10 is equipped with a driving device for driving the truck. The driving device includes a diesel engine 1, a transfer case 2, an oil pump 3, a water supply tank 4 and a hydraulic oil tank 9, and a radiator is arranged in front of the diesel engine 1. 12. The hydraulic oil tank 9 and the water supply tank 4 are arranged symmetrically on both sides of the front car 10, which not only avoids the air duct of the radiator 12, but also facilitates the air circulation, and increases the internal space of the front car 10, so that future pipeline layout And maintenance is more convenient. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com