Method for preparing nano-porous light silicon oxide microspheres

A lightweight silica and nanoporous technology, applied in the direction of silica, silicon oxide, nanotechnology, etc., can solve the problems of complex process and high cost, and achieve simple preparation process, low production cost and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Mix 100g of water glass (modulus 3.0) with 300g of deionized water at room temperature, add 50g of hydrochloric acid (37 wt%) and 300g of n-hexane, stir well to obtain a mixed solution; add 10g of Tween-20 to the mixed solution Surfactant, after stirring rapidly at 400rpm to make the system form an emulsion, add 10g of dimethyldiethoxysilane to it, stir and react at 30°C for 3h, after the reaction is over, let stand, filter, A white precipitate was obtained; the white precipitate was washed with n-hexane for 3 times, then placed in a blast drying oven, and dried at 100° C. for 6 hours to obtain white nanoporous light silica microspheres.

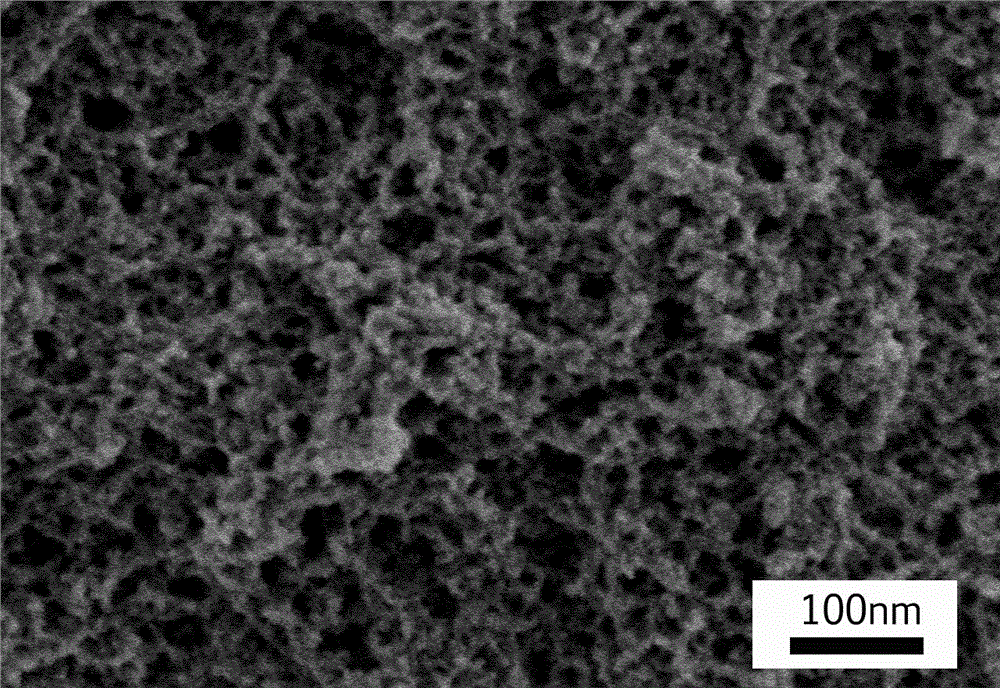

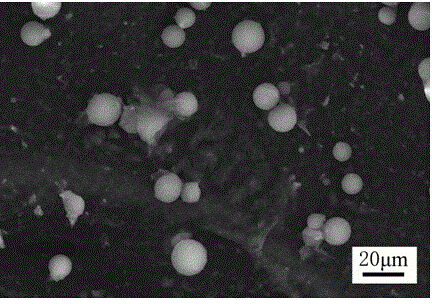

[0030] The scanning electron microscope image of the prepared nanoporous lightweight silica microspheres is shown in the attached figure 1 And attached figure 2 As shown, the particles are spherical, and the particle size distribution is between 10 and 20 μm. figure 2 It can be seen that the prepared nanoporous lightweight silica ...

Embodiment 2

[0037]Mix 100g of water glass (modulus 3.0) with 800g of deionized water at room temperature, add 120g of perchloric acid ((50 wt %) and 600g of n-heptane, and stir to obtain a mixed solution; add 1g of Tween-40 surfactant, after stirring rapidly at 1500rpm to make the system form an emulsion, add 90g of octamethylcyclotetrasiloxane to it, and stir and react at 60°C for 1.5h. After the reaction, Stand still and filter to obtain a white precipitate; wash the white precipitate 3 times with n-heptane, then place it in a blast drying oven, and dry it at 80°C for 3 hours to obtain a white nanoporous light silica microparticle. ball.

[0038] Test Results:

[0039] Particle size: 50~120μm;

[0040] Bulk density: 0.15g / cm3;

[0041] Specific surface area: 1000 m2 / g;

[0042] Average pore diameter: 80nm.

Embodiment 3

[0044] Mix 100g of water glass (modulus 3.2) with 600g of deionized water at room temperature, add 100g of hydrochloric acid (37 wt%) and 1200g of n-octane, and stir to obtain a mixed solution; add 20g of Tween- 60 surfactant, after the system forms an emulsion by rapid stirring at 800rpm, add 80g of dodecyltriethoxysilane to it, stir and react at 50°C for 1.5h, after the reaction is over, let it stand , filtered to obtain a white precipitate; the white precipitate was washed 3 times with n-octane, then placed in a blast drying oven, and dried at 180 ° C for 2 hours to obtain white nanoporous light silica microspheres.

[0045] Test Results:

[0046] Particle size: 1~20μm;

[0047] Bulk density: 0.05g / cm3;

[0048] Specific surface area: 1200 m2 / g;

[0049] Average pore diameter: 10nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com