Composite self-heating reflecting layer energy-gathered semiconductor ignition bridge

A technology of semiconductor and reflective layer, applied in the direction of offensive equipment, fuze, etc., can solve the problem of low ignition energy, achieve the effects of reducing heat loss, improving energy utilization, and improving ignition capability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention is described in further detail:

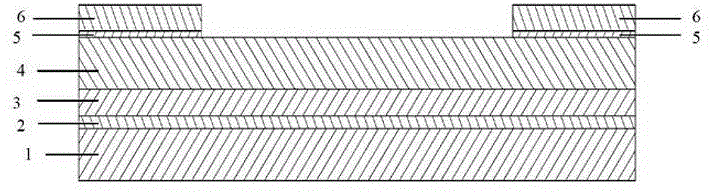

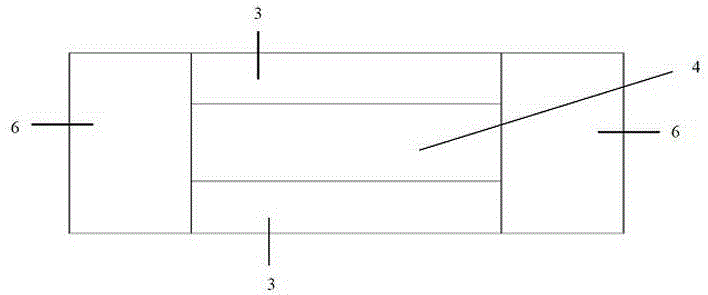

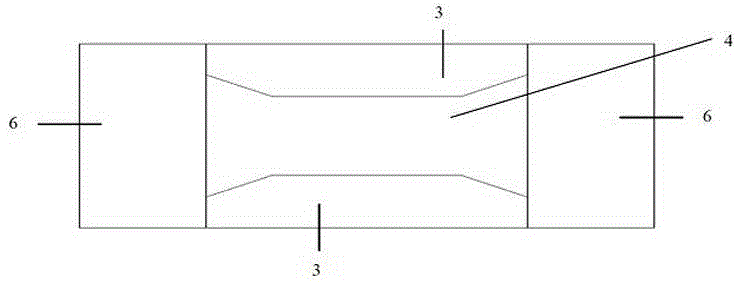

[0020] A compound self-heating reflective layer energy-gathering semiconductor ignition bridge, such as figure 1 As shown, the ignition bridge body consists of a base layer 1, an insulating layer 2, a heat-absorbing energy-gathering reflective layer 3, a semiconductor bridge layer 4, a discrete solder layer 5 and a discrete electrode layer 6 (electrode 1, electrode 2) from bottom to bottom The above are stacked sequentially; the base layer 1, the insulating layer 2, and the heat-absorbing and energy-gathering reflective layer 3 are all rectangular in shape and the same size, and the semiconductor bridge layer 4 is narrow in the middle and wide at both ends, such as figure 2 with image 3 As shown, it can be a butterfly shape, an H shape, or a more complex shape. The discrete electrode layers 6 are separated from each other and cover the wide part at both ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com