Asphalt composition particle and preparation method thereof

A technology of asphalt composition and granules, which is applied in the field of high softening point asphalt composition granules and its preparation, which can solve the problems of reduced effective components of asphalt powder, limited deformation capacity of granules, and damage to mud system, so as to reduce high-temperature and high-pressure filtration loss , increase the deformability, improve the effect of compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

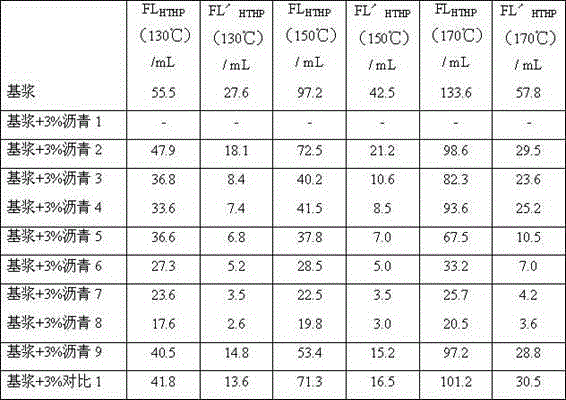

Examples

Embodiment 1

[0031] Take 200g of high softening point asphalt with a softening point of 153°C, add 3.5% hexadecyltrimethylammonium chloride, freeze at -5°C for 3 hours, pulverize in a small universal grinder for 15 seconds, and use the obtained asphalt powder with 60 Mesh and 80 mesh standard sieves are used to obtain 60-80 mesh high softening point asphalt granules. Take 85g of styrene-butadiene latex (40% solid content) in a watering can, spray the latex evenly on the asphalt particles obtained in the above test, and stir while spraying. After spraying, let it stand at room temperature for 30 minutes, and perform vacuum freeze-drying (pre-freezing temperature is -40°C, pre-freezing time is 2 hours, drying temperature is -20°C, drying time is 10 hours) to obtain asphalt composition particles.

Embodiment 2

[0033] Take 200 g of high softening point asphalt with a softening point of 172.8°C, freeze it at -10°C for 4.5 hours, and pulverize it in a small universal grinder for 20 seconds. The asphalt powder obtained is sieved with 80-mesh and 100-mesh standard sieves to obtain 80-100-mesh high softening point asphalt. Take 96g of neoprene latex (solid content 30%) and put it in a watering can, spray the latex evenly on the asphalt particles obtained in the above test, and stir while spraying. After spraying, let stand at room temperature for 45 minutes. Add 5.0% sodium lignosulfonate, mix well, and carry out vacuum freeze-drying (prefreezing temperature -30°C, prefreezing time 2.5 hours; drying temperature -18°C, drying time 12 hours) to obtain asphalt composition granules.

Embodiment 3

[0035]Take 200g of high softening point asphalt with a softening point of 146.6°C, add 6.0% sodium secondary alcohol sulfate, freeze at -25°C for 5.5 hours, pulverize in a small universal pulverizer for 30 seconds, and use 100 mesh and 120 mesh standard Sieve to obtain 100-120 mesh high softening point asphalt. Take 128g of nitrile latex (solid content 30%) and place it in a watering can, spray the latex evenly on the asphalt particles obtained in the above test, and stir while spraying. After spraying, let stand at room temperature for 60 minutes. Vacuum freeze drying (prefreezing temperature -35°C, prefreezing time 3 hours; drying temperature -25°C, drying time 15 hours) to obtain asphalt composition particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com