Method for generating super-high giant magneto impedance effect on amorphous microwire

An amorphous microwire and giant magneto-impedance technology, which is applied in the field of amorphous microwire with extremely high giant magneto-impedance effect, can solve problems such as no related reports on amorphous microwire, and achieves easy repeatable annealing and simple equipment and process. , the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

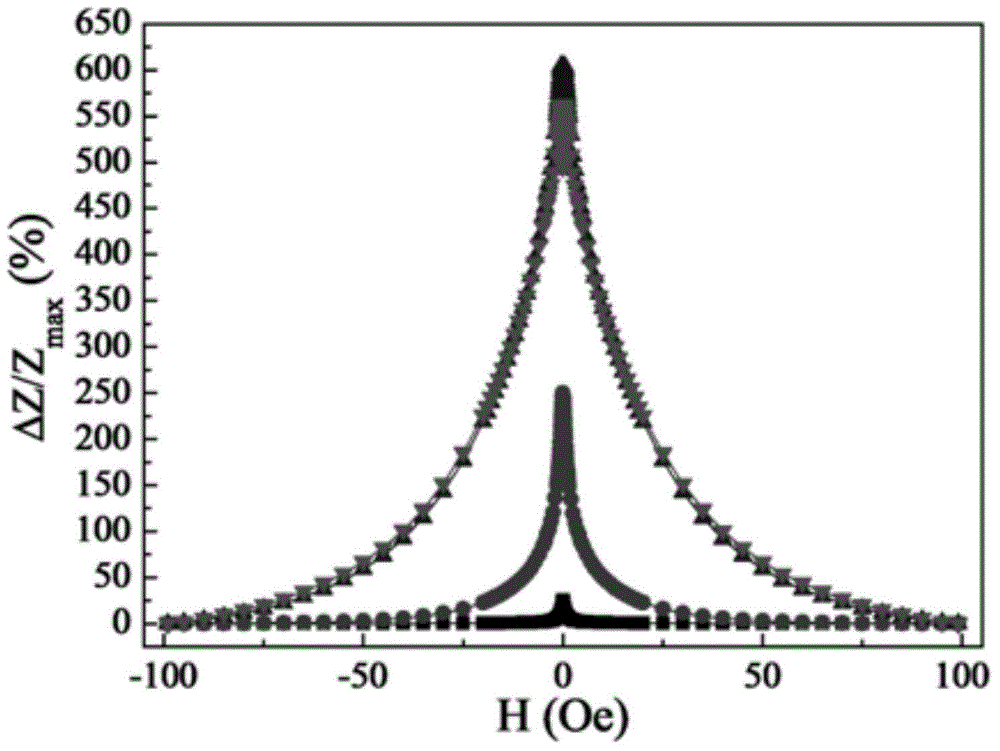

[0018] Specific embodiment one: a kind of amorphous microwire of this embodiment has the method for very high giant magneto-impedance effect to carry out according to the following steps:

[0019] 1. Select Co 68.15 Fe 4.35 Si 12.25 B 13.25 Nb 1 Cu 1 For amorphous microwires, the two ends of the microwires are fixed with copper flat-head fixtures, and placed in a zero-magnetic shielding space for impedance testing;

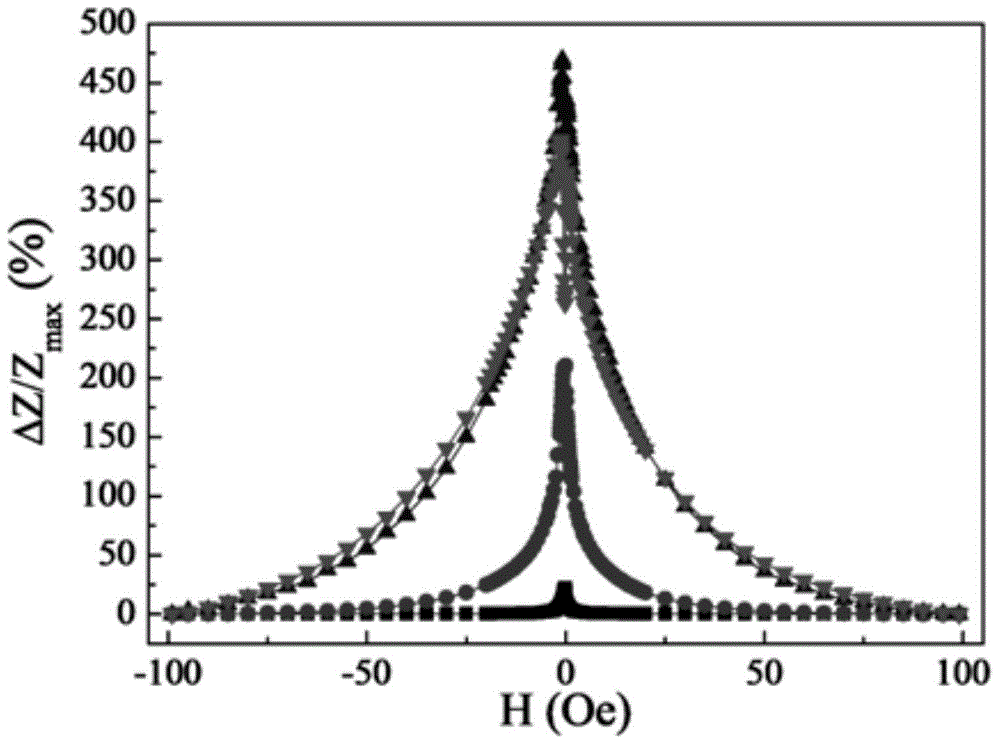

[0020] 2. After completing the impedance test of step 1, connect the microwire and the copper fixture into the circuit with a stable DC power supply, and perform the first step of step Joule annealing: the annealing current is 30-40mA, and the annealing time 8 to 10 minutes, after completion, connect it to the impedance test circuit for impedance test;

[0021] 3. After completing the first step of step two step Joule annealing, carry out the second step of step Joule annealing. The annealing current is 50-60mA, and the annealing time is 8-10min. After compl...

specific Embodiment approach 2

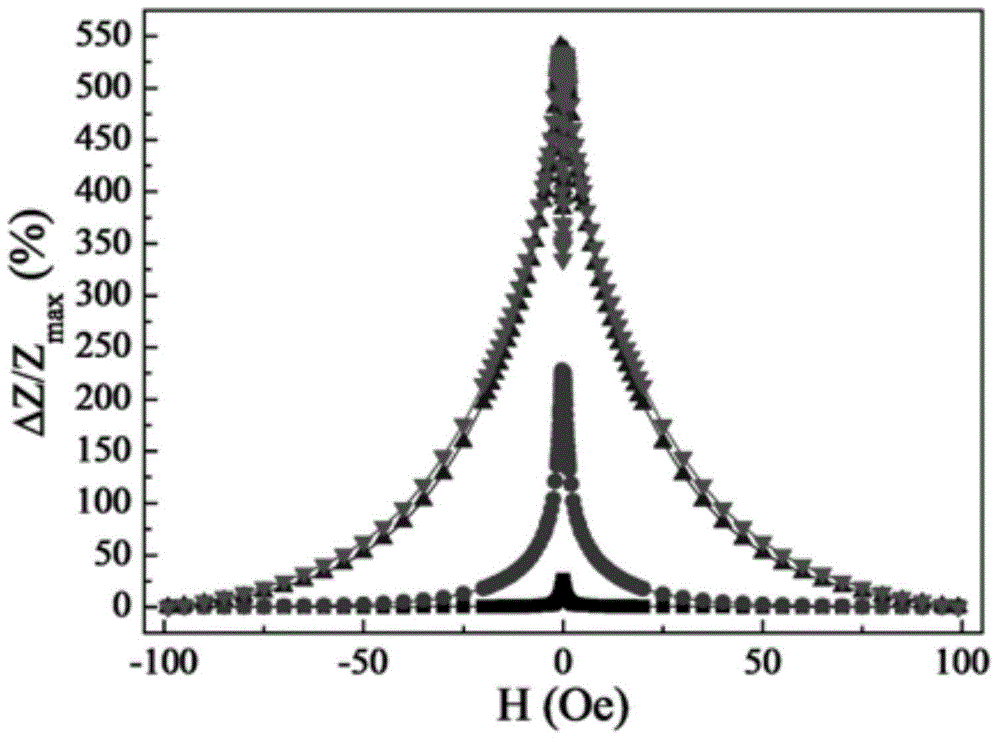

[0027] Embodiment 2: This embodiment is different from Embodiment 1 in that: in step 2, the annealing current is 40 mA, and the annealing time is 10 min. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0028] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: in Step 3, the annealing current is 60 mA, and the annealing time is 10 min. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com