Zinc powder sherardizing method of machined steel product with no hydrogen embrittlement and low surface damage

A technology of machining and powder galvanizing, applied in metal material coating process, coating, solid-state diffusion coating, etc. hidden dangers and other problems, to achieve the effect of avoiding the hidden danger of hydrogen embrittlement and low surface damage by hot galvanizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

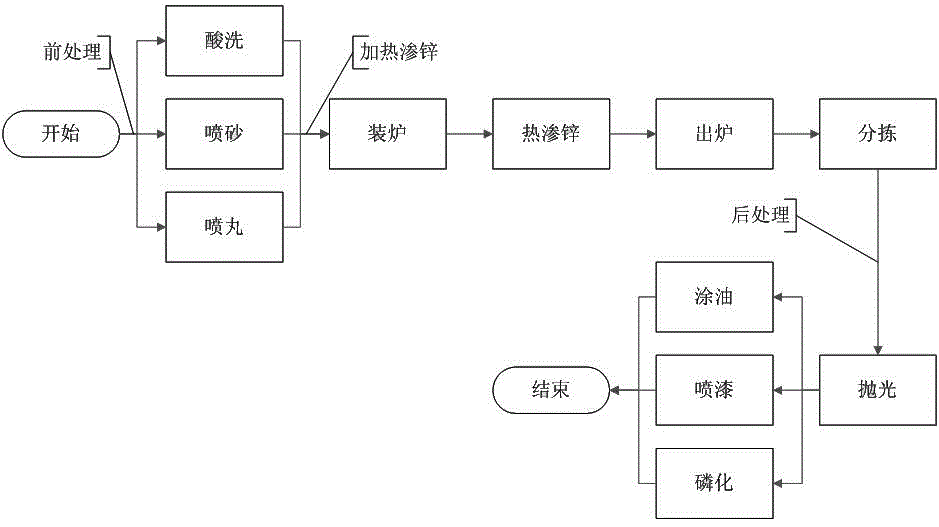

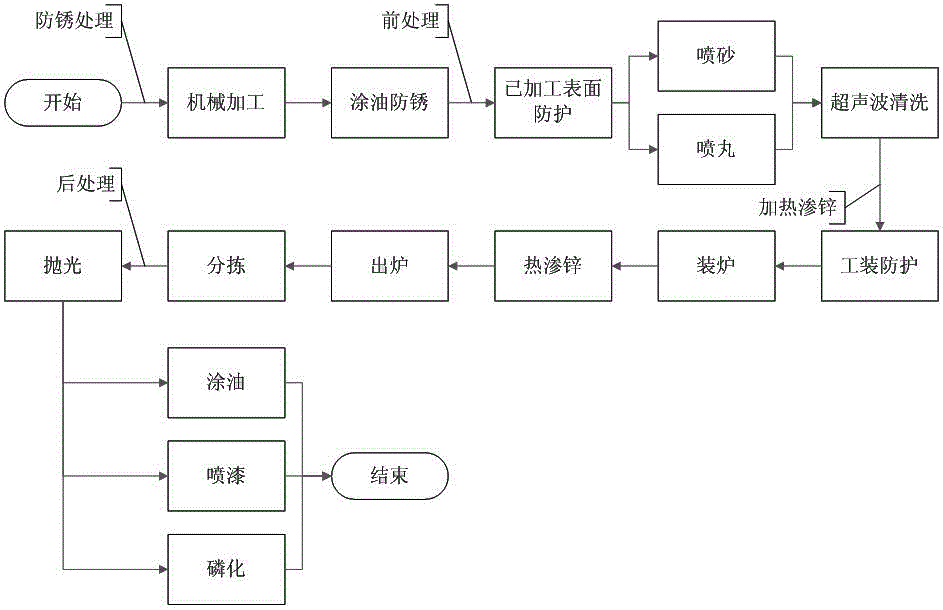

Method used

Image

Examples

Embodiment 1

[0053] A method for mechanically processing thin-walled iron and steel cylinder parts without hydrogen embrittlement and low surface damage powder galvanizing method, comprising the following steps:

[0054] 1) Anti-rust treatment of machined steel parts

[0055] After finishing or final machining of machined steel parts, the machined surface is coated with anti-rust oil for oil sealing, and no other surface treatment is performed before the pre-treatment process of powder galvanizing;

[0056] 2) Pre-processing

[0057] Use ultrasonic cleaning to remove oil stains on the surface of the workpiece;

[0058] 3) Heating zinc sherardizing

[0059] Before the parts are loaded into the furnace, the parts are hot-dip galvanized after being bundled with barbed wire.

Embodiment 2

[0061] A method for mechanically processing thin-walled iron and steel cylinder parts without hydrogen embrittlement and low surface damage powder galvanizing method, comprising the following steps:

[0062] 1) Anti-rust treatment of machined steel parts

[0063] After finishing or final machining of machined steel parts, the machined surface is coated with anti-rust oil for oil sealing, and no other surface treatment is performed before the pre-treatment process of powder galvanizing;

[0064] 2) Pre-processing

[0065] Use ultrasonic cleaning to remove oil stains on the surface of the workpiece;

[0066] 3) Heating zinc sherardizing

[0067] Before the parts are loaded into the furnace, the parts are hot-dip galvanized after being bundled with barbed wire.

Embodiment 3

[0069] A method for mechanically processing thin-walled iron and steel cylinder parts without hydrogen embrittlement and low surface damage powder galvanizing method, comprising the following steps:

[0070] 1) Anti-rust treatment of machined steel parts

[0071] After finishing or final machining of machined steel parts, the machined surface is coated with anti-rust oil for oil sealing, and no other surface treatment is performed before the pre-treatment process of powder galvanizing;

[0072] 2) Pre-processing

[0073] Use ultrasonic cleaning to remove oil stains on the surface of the workpiece;

[0074] 3) Heating zinc sherardizing

[0075] Before the workpiece is loaded into the furnace, the workpiece is hot-dip galvanized after being treated by means of tooling isolation.

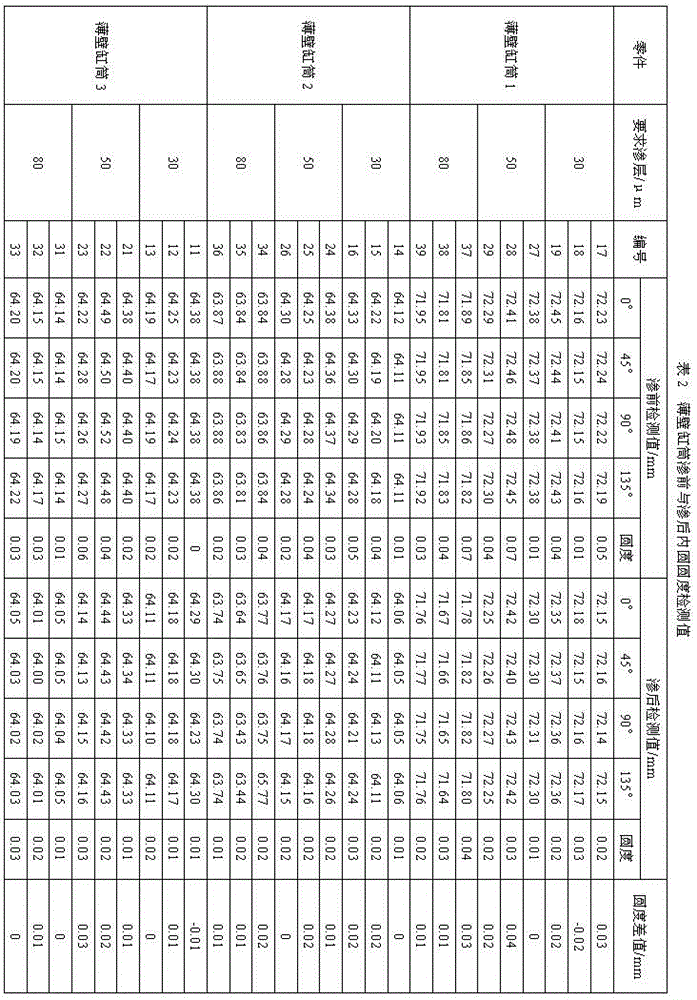

PUM

| Property | Measurement | Unit |

|---|---|---|

| Circularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com