Device for ball surface coating

A surface coating and rolling ball technology, which is applied in sputtering coating, ion implantation coating, vacuum evaporation coating, etc., can solve the problems of uneven coating and affecting the quality of film formation, and achieve simple structure, uniform film layer, The effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0020] The invention provides a device for coating the surface of a ball, wherein the device is in a vacuum chamber.

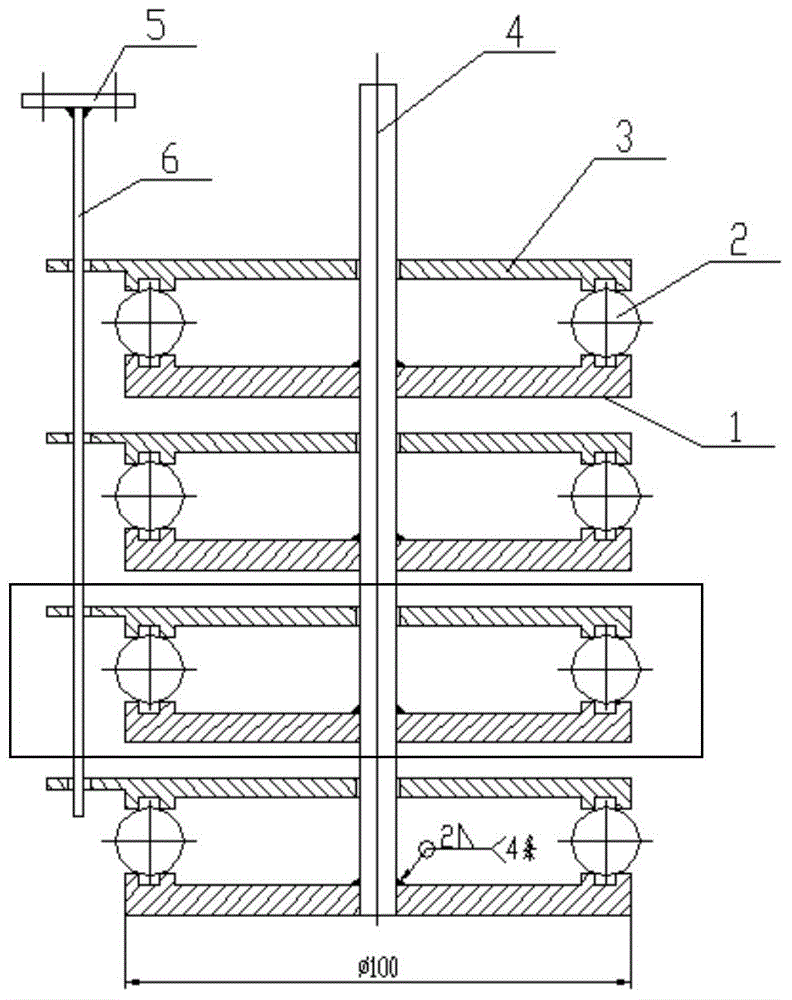

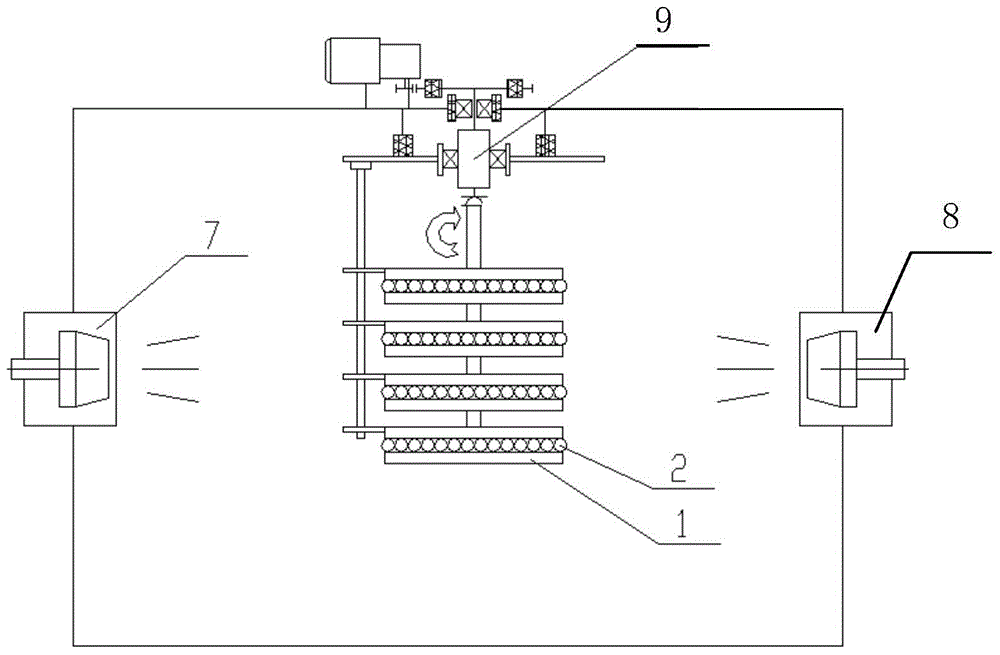

[0021] see figure 1 , the ball surface coating device of a preferred embodiment of the present invention includes a rotating shaft 4, a tooling frame 11, a target source 7, an ion source 8 and a transmission device 9;

[0022] The tooling frame is composed of a fixed plate 5, a fixed rod 6, a rotating shaft 4 and a plurality of rotating assemblies; wherein, each rotating assembly is composed of an upper rotating disk 3 and a lower rotating disk 1, and the upper rotating disk 3 and the lower rotating disk 1 are on the opposite surfaces. A circle of annular groove is processed; the structure of the annular groove can not only play a limiting role, but also reduce the probability of adhesion between the ball and large particles due to the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com