Finishing Method for Improving Durable and Waterproof Function of Nylon Fabric

A waterproof finishing and fabric technology, which is applied in the field of textile printing and dyeing, can solve the problems of unable to meet the requirements of waterproof function, expensive bridging agent, and decreased waterproof effect, so as to reduce color fastness, increase processing procedures, and improve washability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

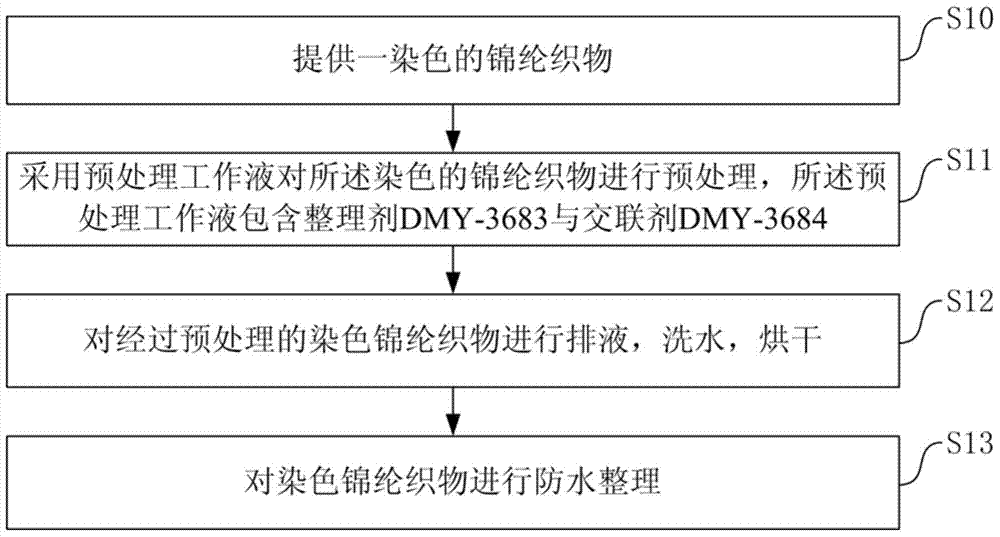

[0016] The specific implementation of the finishing method for improving the durable waterproof function of nylon fabric provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] see figure 1 The finishing method for improving the durable waterproof function of nylon fabric of the present invention comprises the following steps: step S10, providing a dyed nylon fabric; step S11, using a pretreatment working solution to pretreat the dyed nylon fabric, and the pretreatment work The liquid contains finishing agent DMY-3683 and crosslinking agent DMY-3684; step S12, draining, washing and drying the pretreated dyed nylon fabric; step S13, performing waterproof finishing on the dyed nylon fabric.

[0018] Step S10, providing a dyed nylon fabric. The formula of the dyed working solution is shown in Table 1.

[0019] The formula of the working solution of table 1 dyeing

[0020]

red

blue

Acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com