Anti-sinking rapid assembling platform

A fast splicing and platform technology, applied in the platform field, can solve the problems of slow assembly and disassembly, inconvenient cleaning, easy damage, etc., and achieve the effect of beautiful area, simple structure and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

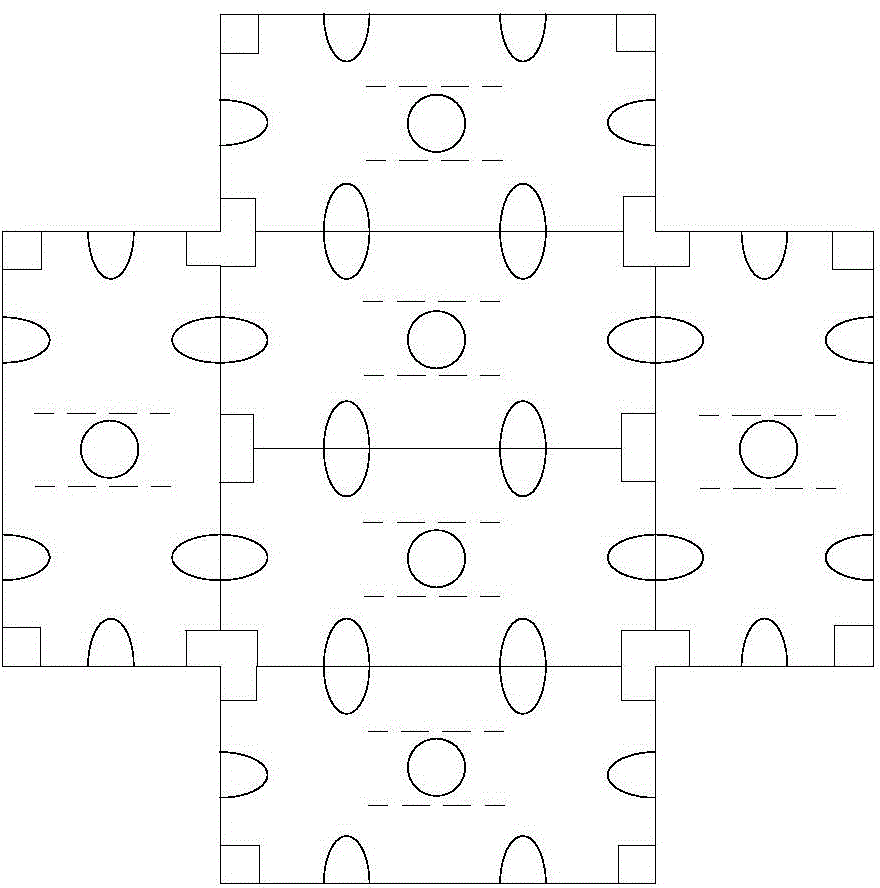

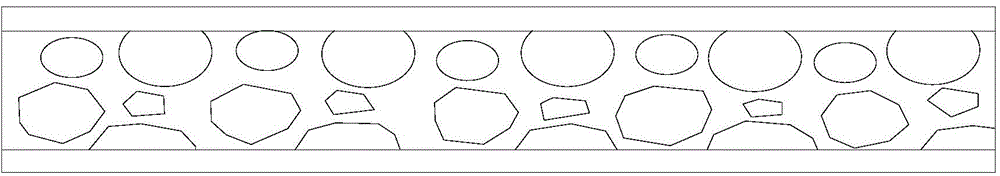

[0026] like figure 1 and figure 2 As shown, the anti-collapse rapid assembly platform of the present invention includes two or more splicing modules, and the splicing modules are connected to each other by side bolts and corner positioning cards. Each splicing module is composed of 6 identical rectangular splicing modules. board composition;

[0027] The rectangular splicing plate is composed of a composite structural plate and a groove frame connected on both sides of the composite structural plate. There are side bolt holes on the groove frame on the four sides of the rectangular splicing plate, and the side bolt holes are located on the composite structural plate. There are bolt mounting holes;

[0028] There are corner positioning card installation holes at the four corners of the rectangular splicing board;

[0029] The length of the rectangular splicing board is twice the width, the long sides of the two rectangular splicing boards are spliced side by side with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com