Plant dedusting wastewater treatment device

A technology for wastewater treatment and workshops, applied in waterway systems, water supply devices, sewer systems, etc., can solve the problems of secondary pollution, large dust slag, dust slag transportation, etc., to prevent secondary pollution, collect and treat secondary The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] to fully understand A plant dedusting wastewater treatment equipment The purpose, features and effects of the present invention will now be described in detail through the following specific embodiments in conjunction with the accompanying drawings.

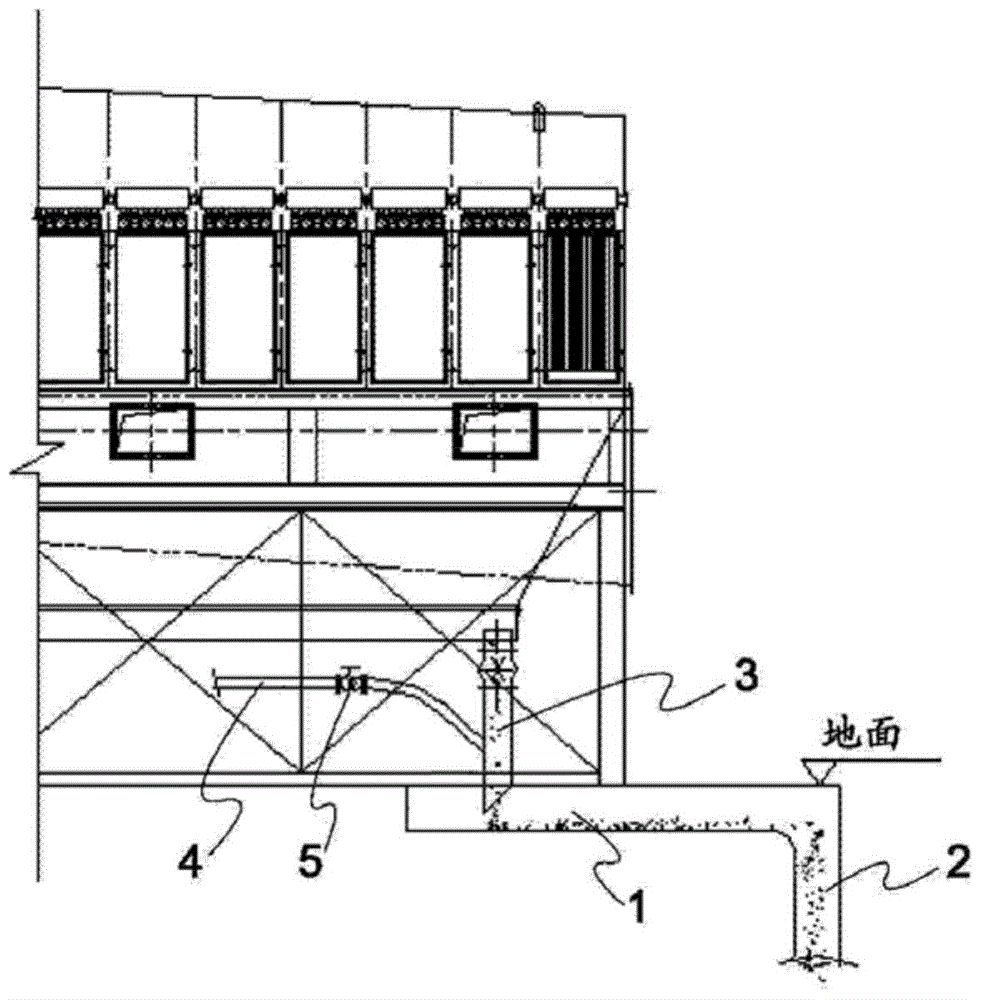

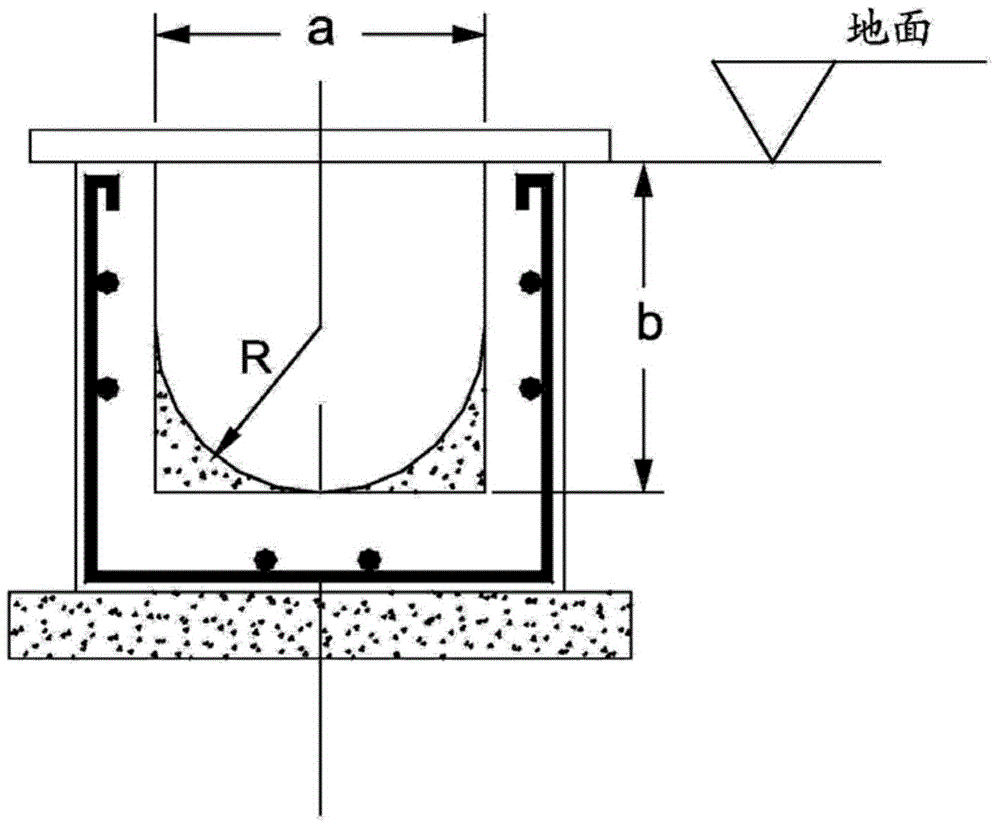

[0012] Such as figure 1 As shown, the ash unloading area of the factory dust collector is generally provided with a dust discharge pipe 3, and the present invention arranges a pipeline 4 for flushing waste water on the dust discharge pipe 3, so as to flush the dust slag discharged from the ash discharge pipe 3 to the outlet connected to it. Drain sewer 1. The other end of the drainage ditch 1 is connected to the lower drainage pipe 2, and the end of the lower drainage pipe 2 is connected to the inherent slag flushing pipeline of most workshops. Furthermore, in order to make the dust slag better flush into the main slag flushing pipe of the workshop, the slope of the drainage ditch 1 and the lower drainage waste pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com