Small power deep well pumping unit

A pumping unit, low-power technology, applied in mechanical equipment, wellbore/well components, machines/engines, etc., can solve the problems of accelerated pump damage, short working period, shortened service life, etc., and achieves convenient frequency conversion and speed regulation. , reduce fatigue damage, the effect of low motor power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manner and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

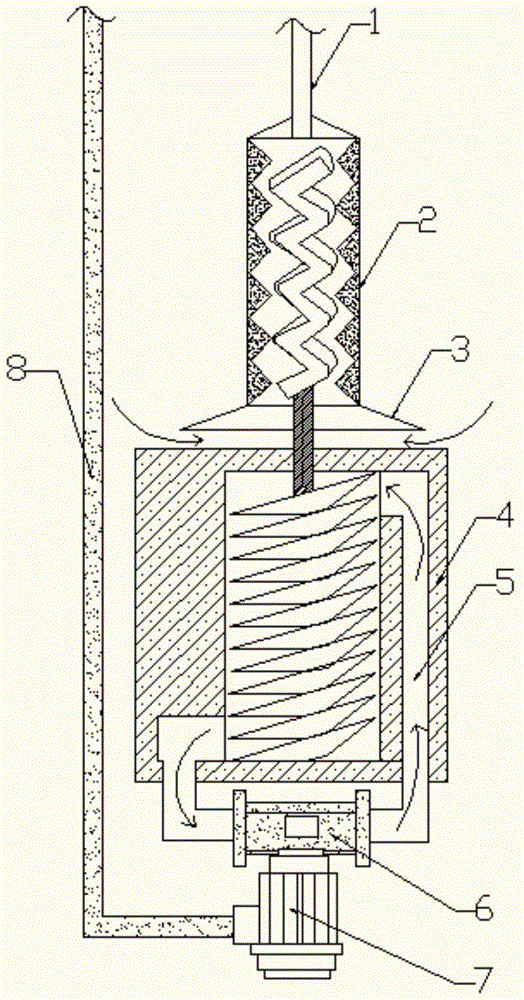

[0016] like figure 1 As shown, a low-power deep well pumping unit includes a turbo pump 4 and a vane pump 6. The outlet of the circulating fluid of the turbo pump 4 is connected to the inlet of the vane pump 6 through a pipeline, and the outlet of the vane pump 6 is connected to the vane pump 6 through a pipeline. The circulating fluid inlet of the turbo pump 4 is connected, and a closed liquid circuit circulation channel is formed between the turbo pump 4 and the vane pump 6 and filled with circulating fluid. The rotating shaft of the vane pump 6 is connected downward to the output of the drive motor 7 On the shaft phase, a cable 8 is connected to the drive motor 7, and the rotating shaft of the turbo pump 4 is connected upward to the rotating shaft of the screw pump 2, and the lower end of the scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com