Method for measuring pressure of gas in coal seam in fracture rock stratum

A coal seam gas pressure and measurement method technology, applied in drilling equipment and methods, measurement, earthwork drilling and mining, etc., can solve the problems of poor pressure bearing effect of drilling holes, unfavorable high-pressure grouting, unsuitability, etc., and achieve enhanced hole sealing Quality, strong applicability, and the effect of avoiding crack problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

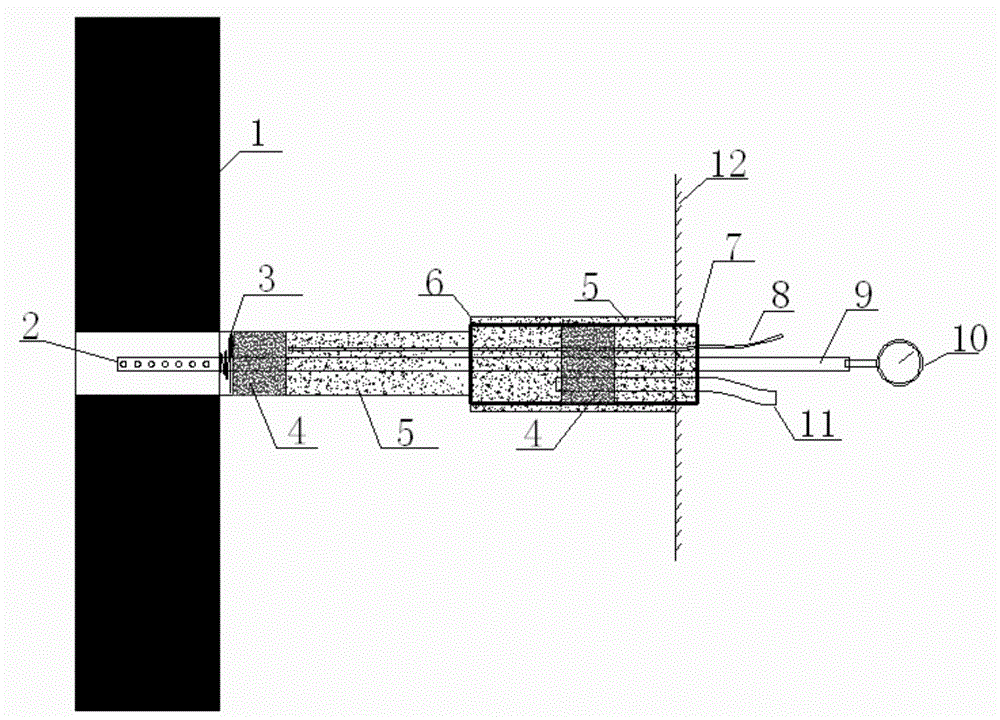

[0011] The present invention will be further described in conjunction with the accompanying drawings.

[0012] as attached figure 1 As shown, the method for measuring coal seam gas pressure in fractured rock formations includes the following steps: (1) Drilling a 6m-long hole with a diameter of 133mm for pressure measurement; (2) inserting a 6m long hole with a diameter of 108mm After sealing the orifice pipe 7, use cement slurry to fill the outer space of the orifice pipe 7 and solidify the pipe; (3) After 48 hours of solidification, inject water into the orifice pipe 7 for pressure test, and the test pressure shall not be less than 6MPa, stable for 10 minutes without water leakage is qualified, otherwise re-grouting; (4) After the solid pipe is qualified, use a drill bit with a diameter of 89mm to sweep the hole along the orifice pipe 7 to the mudstone of the coal seam floor (drill the down hole to the coal seam roof) Stop the construction (the length of the rock hole is no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com