Box liquid level sensor

A liquid level sensor and tank technology, applied in liquid level indicators, instruments, machines/engines, etc., can solve the problems of easy crystallization and blockage of urea solution, complex structure of liquid level sensor, high sealing requirements, etc., to achieve product resistance Good vibration performance, solve the problem of exhaust emission, and strong ability to adapt to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with drawings and embodiments.

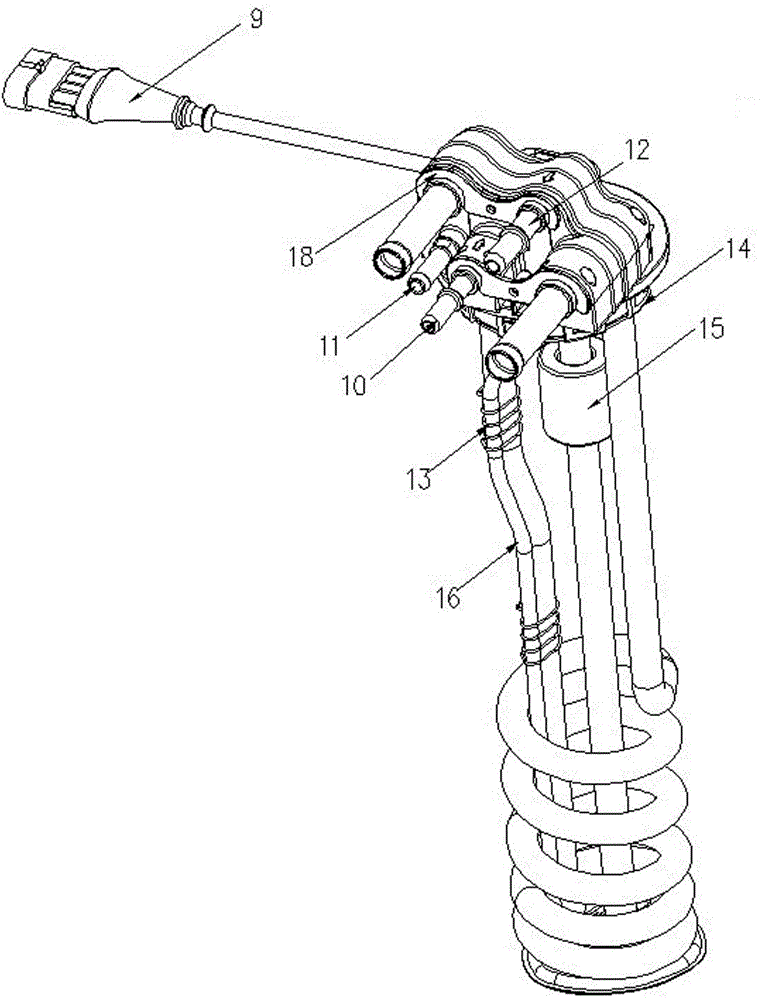

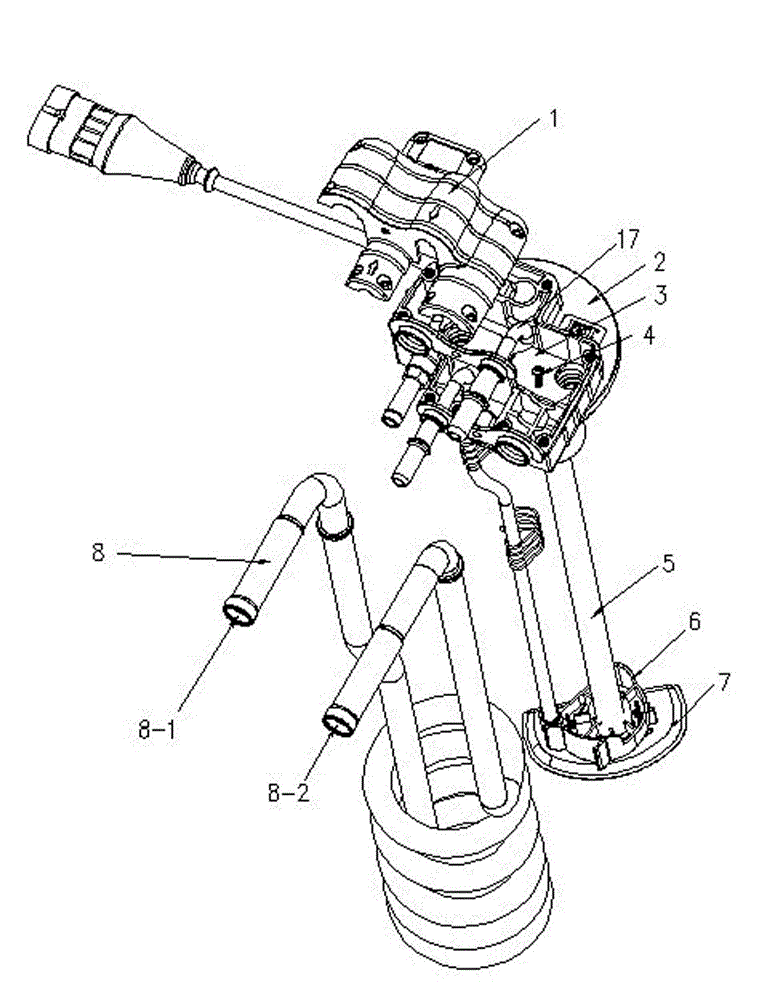

[0021] refer to figure 1 , figure 2 , a tank liquid level sensor, including a fixed seat, one side of the fixed seat is provided with a connector 9 for transmitting signals, the fixed seat is composed of a fixed seat main body 2 and an upper cover 1, and there is an electronic tube 5 under the fixed seat main body 2 , the upper end of the electronic tube 5 is installed on the main body 2 of the fixed seat, the magnetic buoy 15 that can move up and down along the electronic tube 5 is installed on the electronic tube 5, and the urea suction tube 16 that can extend into the inside of the urea tank is equipped with the bottom of the fixed seat main body 2. Pipe 17 and hot water pipe 8; the head end of the urea suction pipe 16 is provided with a urea suction pipe joint 10, the head end of the urea return pipe is provided with a urea return pipe joint 12, and the hot water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com