Compressed air energy storage system

A compressed air energy storage and energy storage technology, which is applied in the direction of gas turbine devices, machines/engines, mechanical equipment, etc., can solve the problem of demanding gas storage conditions in compressed air energy storage power stations, difficulties in natural gas supply, and impacts on compressed air energy storage technology Problems such as popularization and application, to achieve the effect of reducing the requirements of site selection conditions and increasing the overall output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention are described in detail below:

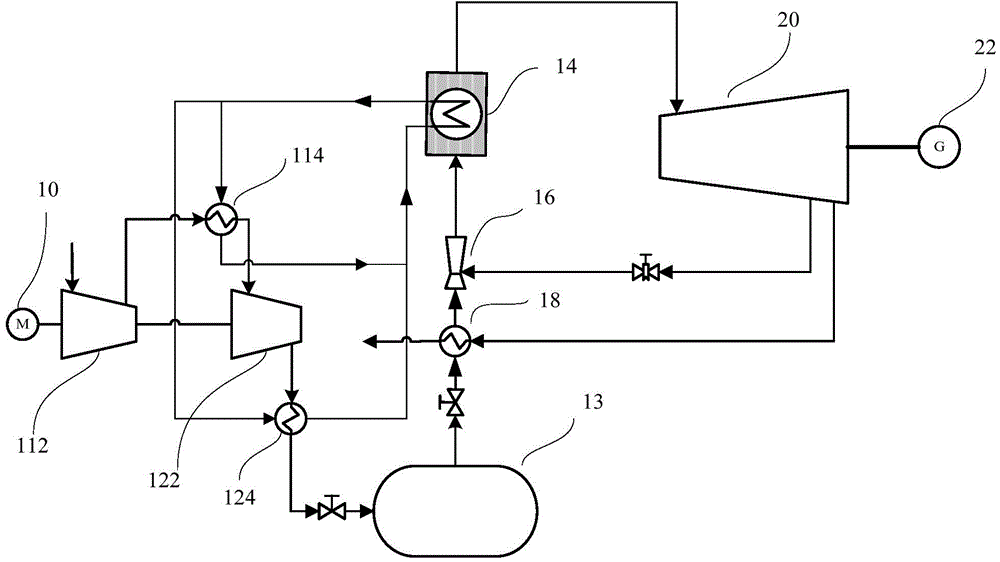

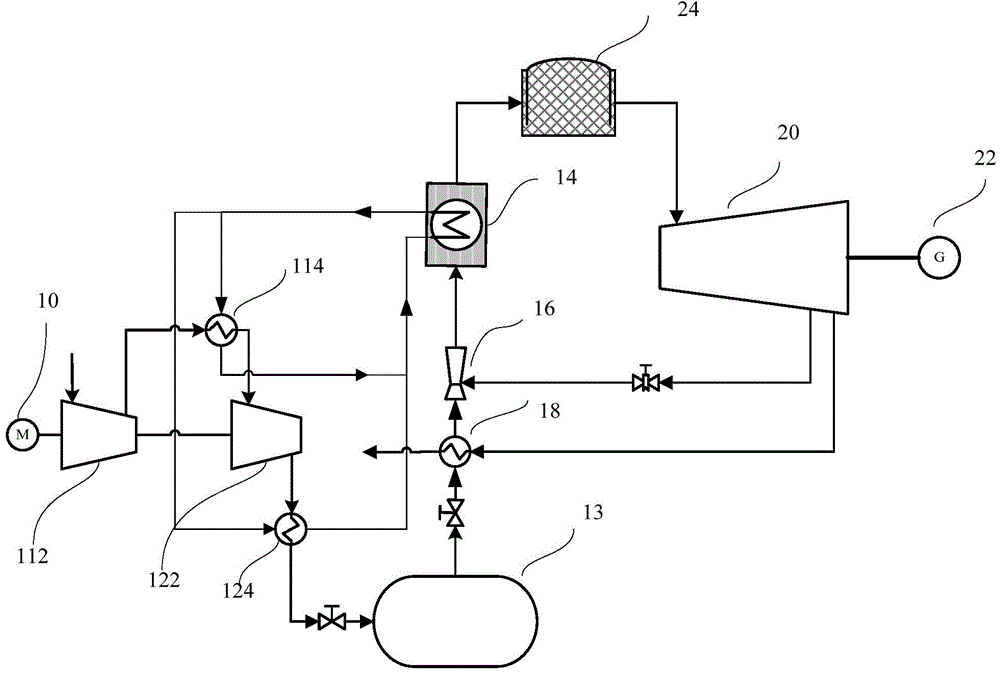

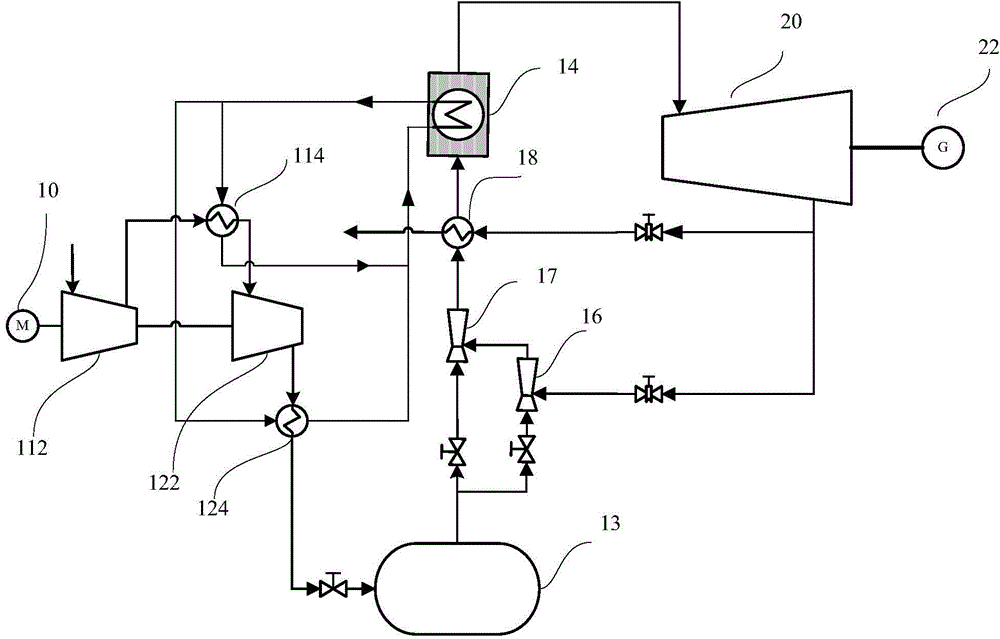

[0030] Such as figure 1 As shown, a compressed air energy storage system includes an energy storage part and an energy release part, and the energy release part includes an ejector 16, a first heat storage / heat exchanger 14, a turbo expander 20 and a generator 22 , the energy storage part is connected to the inlet of the ejector 16, and the outlet of the ejector 16 is connected to the first heat storage / heat exchanger 14, and the first heat storage / heat exchanger 14 is connected to the The inlet of the turboexpander 20 is connected, the entrainment port of the ejector 16 is connected to the turboexpander 20 for air extraction, and the turboexpander 20 is connected to the generator 22 .

[0031] In the energy release part of the compressed air energy storage system, the air compressor in the energy storage part injects compressed air into the air storage chamber 13, and at the same time, the compresse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com