Loading control method of pump and valve composite dual-degree-of-freedom electro-hydraulic motion

A control method and technology of degrees of freedom, applied in the field of simulation, can solve problems such as excess force interference of steering gear motion, and achieve the effects of flexible implementation, high energy utilization efficiency, and reduced throttling loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

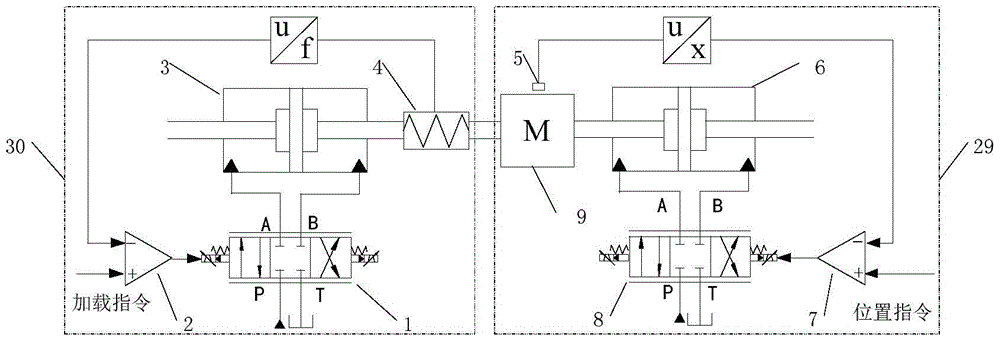

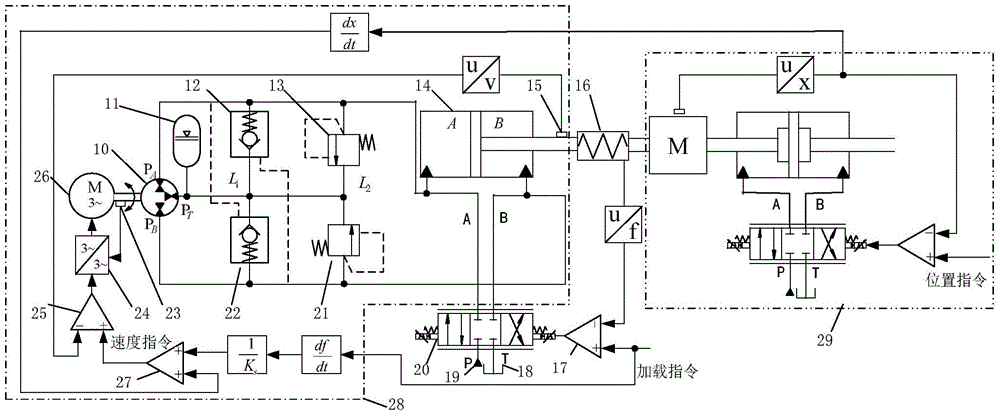

[0020] The present invention will be further described below with reference to the accompanying drawings.

[0021] The innovation of the present invention is to decompose the motion loading task of the electro-hydraulic load simulator based on the idea of functional division of labor: the first goal is to track the speed synchronous motion of the steering gear and decouple the interference caused by the active motion of the steering gear; Instruction tracking task. Aiming at goal 1, the pump-controlled speed servo subsystem based on speed adjustment is used to achieve, and for task 2, the valve-controlled pressure servo subsystem using an independent pressure source is used to achieve, through the independent coordinated control of the speed servo subsystem and the pressure servo subsystem , to realize the dual-degree-of-freedom control of the speed and output force of the electro-hydraulic load simulator. The invention can not only physically decouple the motion interferen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com